CCD Visual Position Laser Marking Machine

CCD Laser Marking Machine: The Ultimate Solution for Zipper Manufacturers

Is your zipper marking process plagued by low efficiency and high costs? Our CCD Laser Marking Machine is the ultimate solution designed specifically for zipper manufacturers.

The core advantage of this machine lies in its CCD vision recognition system, which automatically locates and precisely marks zippers without any manual placement. This means you can say goodbye to tedious manual operations and achieve fully automatic batch production for your zippers.

It’s not only incredibly fast but also highly precise, capable of marking intricate patterns and tiny text on zippers with clarity and permanence. Choosing our CCD Laser Marking Machine means choosing higher efficiency, lower costs, and superior product quality for every zipper you produce.

CCD visual Position Laser Marking Machine Photo

As a zipper manufacturer, are you looking for a solution to overcome traditional marking challenges, improve production efficiency, and enhance product quality? You may be facing these common pain points:

Low Efficiency: Traditional marking methods require manual, step-by-step operation, which is slow and significantly impacts delivery times, especially for large orders.

Insufficient Precision: Manual operation often leads to positional deviations and inconsistent, blurry patterns, affecting product aesthetics and leading to rework and material waste.

Batch Processing Difficulties: Different sizes and shapes of zippers require frequent jig changes, preventing automated, continuous production.

High Labor Costs: Over-reliance on manual labor increases costs and raises the defect rate due to operator errors.

We understand your frustrations. That’s why we bring you the CCD laser marking machine, specifically tailored for zipper manufacturers. It’s not just a piece of equipment; it’s a complete solution to boost your core competitiveness.

How the CCD Laser Marking Machine Solves Your Pain Points

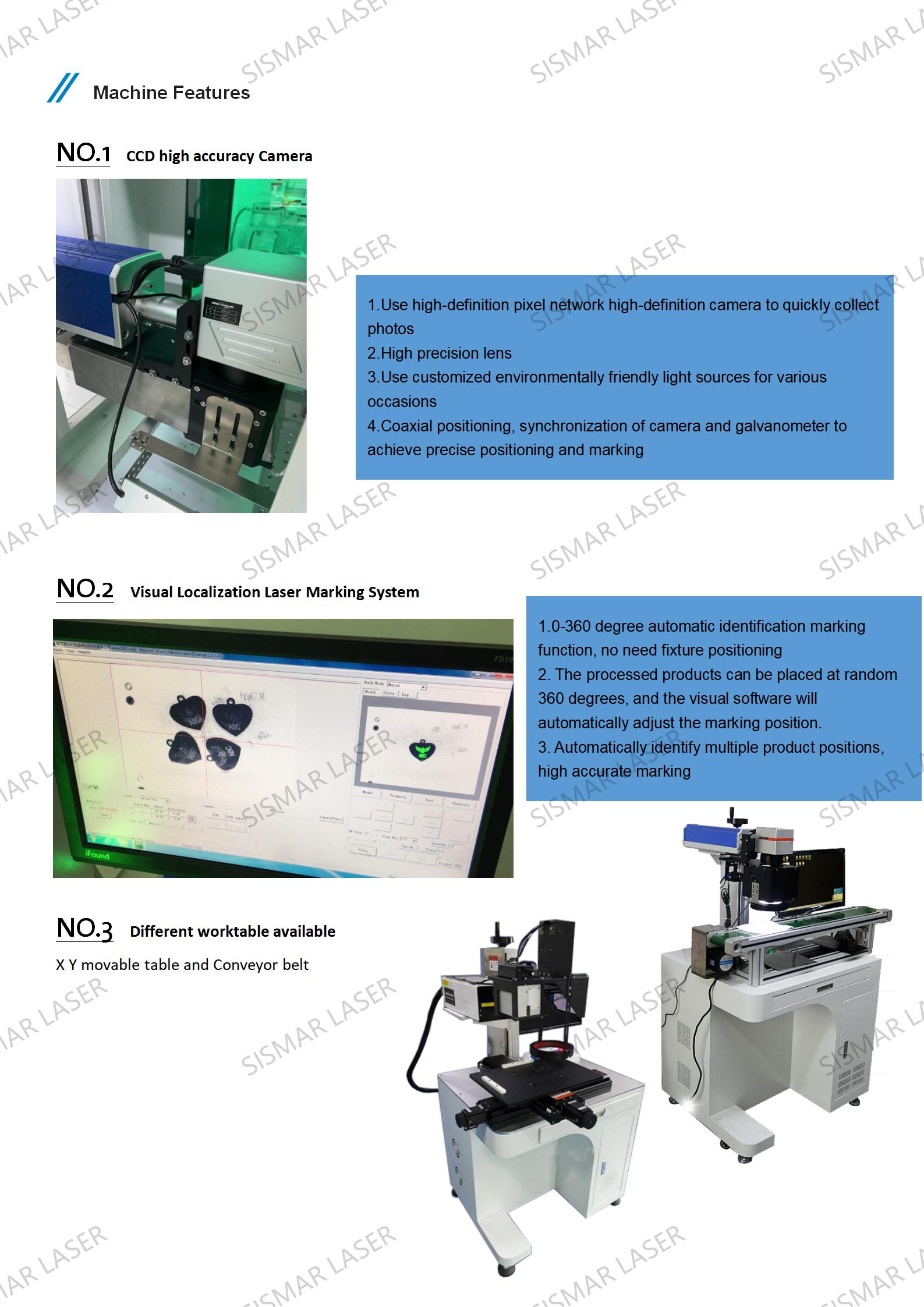

1. Core Advantage: Fully Automatic Recognition & High-Speed Marking

Our CCD laser marking machine for zipper is equipped with an advanced visual positioning system. It automatically captures and precisely identifies different workpieces like zipper pulls and sliders, allowing for jig-free marking. Simply load zippers in bulk, and the machine will automatically recognize and mark them, achieving a truly automated, unmanned production model.

2. Core Advantage: A Perfect Blend of Speed and Precision

The machine uses high-speed galvanometer technology, with marking speeds far exceeding traditional methods, capable of marking hundreds or even thousands of zippers per minute. At the same time, the laser marking precision reaches the micron level, ensuring that complex logos, tiny text, and high-definition QR codes are permanently and clearly marked on the zipper surface, significantly enhancing your product’s premium feel and anti-counterfeiting capabilities.

3. Core Advantage: Versatile and Highly Adaptable

This zipper laser marking solution is not only suitable for various materials like metal, plastic, and nylon but also easily handles different sizes, shapes, and colors of zippers. The software interface is intuitive and easy to use, allowing you to quickly switch between different marking tasks without complex adjustments.

Product Specifications (For Reference)

| Parameter | Technical Specification |

| Laser Type | Fiber Laser |

| Laser Power | 50W |

| Marking Area | 110mm x 110mm (Customizable) |

| Marking Speed | ≤ 7000mm/s |

| Marking Precision | ±0.001mm |

| Working Voltage | AC220V±10% / 50Hz |

| Cooling Method | Air Cooling |

| Vision System | CCD Automatic Recognition and Positioning System |

| Supported File Formats | PLT, DXF, BMP, JPG, CDR, AI, etc. |

| Software System | Dedicated Laser Marking Software |

Broad Range of Applications

Our CCD laser marking machine is not just the perfect zipper manufacturer solution; it’s also ideal for the following industries and products:

Apparel Accessories: Marking on buttons, belt buckles, hardware, etc.

Electronic Products: Marking on phone cases, chargers, data cables, headphones, etc.

Hardware Tools: Marking on screws, wrenches, knives, bearings, etc.

Jewelry: Engraving patterns and text on rings, necklaces, bracelets, etc.

Medical Devices: Marking on scalpels, screws, etc., for traceability and branding.

Zipper Marking: A Comprehensive Comparison Between CCD Laser Marking and Traditional Methods

In the zipper manufacturing industry, choosing the right marking technology is crucial for boosting efficiency and product value. Traditional methods like ink printing and mechanical engraving have significant performance differences when compared to the modern CCD Laser Marking Machine. Here’s a detailed comparison of the two across key production aspects.

1. Automation and Production Efficiency

Traditional Methods (Ink Printing / Mechanical Engraving)

Highly reliant on manual labor: Requires workers to manually place and align zippers one by one, making automation impossible.

Low efficiency: The cumbersome process significantly slows down overall production, especially for large-volume orders, affecting delivery times.

CCD Laser Marking Machine

Fully automated and unmanned: Thanks to its CCD vision recognition system, the machine automatically captures and locates zippers scattered on a tray or conveyor belt, eliminating the need for manual alignment.

Ultra-fast batch production: It can mark multiple zippers within its field of view simultaneously, enabling a “load and mark” automated workflow that increases production efficiency by several times.

2. Marking Quality and Precision

Traditional Methods (Ink Printing / Mechanical Engraving)

Limited precision: Ink printing often results in blurry patterns and unclear edges, affecting the product’s aesthetic. Mechanical engraving can leave burrs and scratches, damaging the zipper’s surface.

Non-durable marks: Ink marks can easily fade, wear off, or rub away due to friction and cleaning, failing to provide a permanent solution.

CCD Laser Marking Machine

High precision with no deviation: The laser beam has a micron-level spot size, allowing it to precisely mark complex logos, tiny text, or QR codes. Each mark is flawless and sharp.

Permanent marking: The laser creates a mark by physically or chemically altering the material’s surface. This makes the marks highly resistant to wear, corrosion, and weathering, ensuring they never fade and enhancing the product’s quality and anti-counterfeiting features.

3. Cost and Maintenance

Traditional Methods (Ink Printing / Mechanical Engraving)

High consumable costs: Requires a continuous purchase of ink, solvents, printing plates, or cutting tools, leading to high long-term operational costs.

Complex maintenance: Equipment needs regular cleaning, and parts like blades or plates need to be replaced, making maintenance time-consuming and cumbersome.

CCD Laser Marking Machine

Zero consumables: As a non-contact process, laser marking produces no consumables, significantly reducing operational costs.

Simple maintenance: The machine has a stable structure. Routine maintenance is minimal, usually just requiring periodic lens cleaning, with virtually no additional maintenance expenses.

4. Flexibility and Environmental Impact

Traditional Methods (Ink Printing / Mechanical Engraving)

Low flexibility: Changing the marking content or design requires new plates or tooling, which is time-consuming and costly.

Environmental pollution: Ink and solvents contain volatile organic compounds (VOCs) that are harmful to the environment and worker health.

CCD Laser Marking Machine

Highly flexible: You can quickly change marking content in the software without any physical adjustments, allowing you to adapt to diverse order requirements easily.

Eco-friendly and pollution-free: The marking process doesn’t produce any chemical waste or pollutants, making it a clean and environmentally friendly manufacturing method.

Conclusion:

The CCD Laser Marking Machine has become the preferred solution for zipper marking due to its clear advantages in automation, precision, low cost, and environmental friendliness. It helps businesses significantly boost production efficiency and product quality while effectively reducing operational costs, allowing them to stay ahead in a competitive market.

Frequently Asked Questions (FAQ)

1. What’s the difference between a CCD laser marking machine and a regular one?

The biggest difference is the CCD vision system. Regular laser markers require a worker to manually align each part, one at a time, which is slow. A CCD laser marker uses its vision system to automatically identify and locate multiple or irregularly placed items at once, enabling true automated batch production.

2. Will laser marking damage the zipper’s surface or material?

No, it won’t. Laser marking is a non-contact process. It uses a high-energy laser beam to create a permanent mark on the material’s surface without causing any physical damage or deformation to the zipper itself. We offer different laser types for various materials like metal, plastic, and nylon to ensure a flawless, non-destructive mark.

3. Will the laser mark fade or wear off over time?

No. Laser marking is permanent. It alters the material’s surface through a physical or chemical reaction, making the mark highly resistant to wear, corrosion, and weathering. The mark won’t fade over time, which also helps with product authenticity and traceability.

4. Is the equipment’s maintenance expensive?

The maintenance cost is very low. A laser marker is a no-consumable device, meaning you won’t need to buy ink, solvents, or cutting tools. Routine maintenance is simple, typically only requiring you to clean the lens, so there are virtually no extra maintenance costs.

5. Is the machine difficult to operate? Will my workers learn quickly?

The software interface is simple and intuitive, making the machine very easy to operate. We provide comprehensive manuals, video tutorials, and professional training to ensure your workers can quickly learn to use the equipment efficiently.

6. What kind of after-sales service do you offer if the equipment has an issue?

We provide a complete after-sales service system, which includes remote technical support, online diagnostics, and on-site repair services. Our professional technical team will respond quickly to ensure your production line runs smoothly and reliably.

7. What types of zippers can your equipment mark?

Our equipment can mark all kinds of zippers and materials, including metal, resin, and nylon zippers, as well as various special shapes of zipper pulls and sliders.

CCD Visual Position Laser Marking Video

Request a Quote for a CCD Visual Position Laser Marking Machine

SISMAR LASER has CCD visual Position laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Create Flawless Jewelry & Crafts with UV Laser Seashell CuttingFebruary 10, 2026 - 4:14 am

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am