How to Laser Cleaning Machine work?

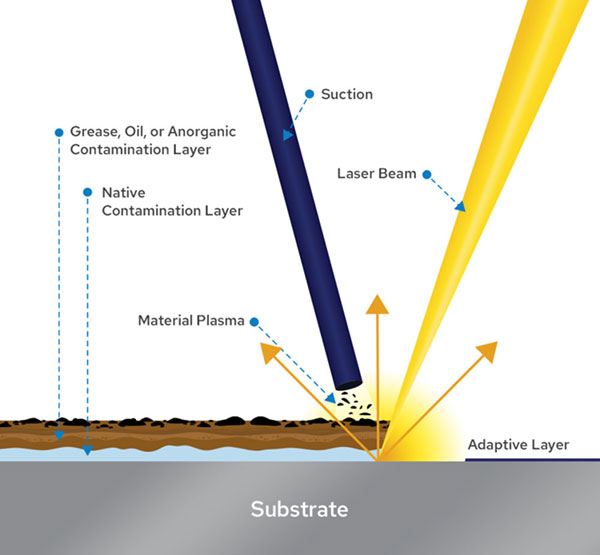

Laser cleaning is the process of removing contaminants, such as rust, oil, oxides, etc., on steel and other surfaces using laser technology. Laser cleaning is achieved through laser ablation. It allows the selective removal of the contaminants with little impact on the substrate.

Laser cleaning uses a machine that aims a laser pulse at high power onto the rusty surface of a material. The laser energy is absorbed by the organic material lying on the surface of the substrate while the non-organic substrate remains untouched.

The laser beam is passed over the surface until the preferred depth and area have been completely rid of the rust.At low flux, the laser energy from the beam ablates the surface while vaporizing the rust. At high flux, the laser energy converts the rust or other unwanted material to plasma. Both low and high flux get the job done, but their use depends on the type of surface in question.

There are two distinct laser cleaning processes; coating removal and surface decontamination. The former is characterized by removing a layer of unwanted material from the surface of a substrate. It is most effective when the physical and chemical composition of the layer differs from the substrate. Such include insulation, primers, corrosion preventive coatings, rubber or paint. Normally, the low flux laser beam is used for this. The latter involves removing the entire upper layer of the substrate and requires high flux laser beams.