600*900mm Mirror Laser Painting Stripping Machine

Ideal for mirror restoration, surface preparation, and industrial cleaning—a must-have tool for various industries.

Laser Paint Stripping Machine: A cutting-edge device that uses high-energy laser beams to precisely remove paint or coatings from various surfaces, including mirrors.

Laser Mirror Stripping Process: When applied to the back of a mirror, the laser paint stripping machine effectively removes the paint layer, leaving the mirror transparent without damaging the underlying glass.

Advantages of Laser Paint Removal for Mirrors: This technology, known as laser mirror stripping or laser paint removal for mirrors, offers a non-destructive and highly efficient solution for paint removal, ensuring the preservation of the mirror’s quality and clarity.

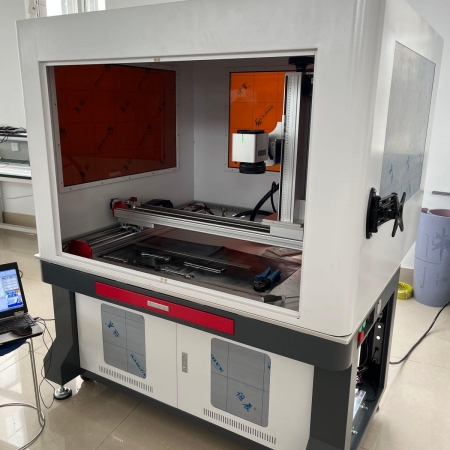

Photos of 600*900mm mirror laser painting stripping machine

1️⃣ Laser Paint Stripping Machine – Precision and Efficiency Redefined ✨

Our Laser Paint Stripping Machine is a state-of-the-art solution designed to effortlessly remove paint and coatings from a variety of surfaces, including glass, metal, and other materials. With this cutting-edge laser technology, you can achieve precise, non-contact cleaning without damaging the substrate. This makes it the ideal choice for mirror back paint removal, mirror restoration, and surface preparation.

2️⃣ Key Features 📋

- High Precision: Remove paint with pinpoint accuracy, leaving the base material untouched and intact.

- Eco-Friendly Technology: Chemical-free and dust-free operation ensures a safe and clean process for both workers and the environment.

- Customizable Settings: Adjustable laser power allows you to handle various paint types and thicknesses with ease.

- Fast and Efficient: Speed up your operations with high-speed removal, making it perfect for industrial and commercial use.

- Non-Contact Process: Reduces wear and tear on materials while providing superior surface protection.

3️⃣ Why Choose Our Laser Paint Stripping Machine? 💡

Experience unmatched precision, reliability, and cost-effectiveness with our advanced laser paint removal technology. Whether you’re working on industrial applications or specialized mirror restoration projects, this machine guarantees outstanding results every time.

4️⃣ Laser Paint Removal for Mirrors 🪞

Our laser paint removal technology is especially designed for mirror applications. Here’s how it stands out:

- Precision Cleaning: The laser targets only the paint layer, ensuring that the glass remains intact, clean, and undamaged.

- Eco-Friendly: Since no chemicals or abrasives are involved, the process is environmentally friendly and safe for long-term use.

- Non-Contact Process: The non-contact nature of the laser minimizes the risk of scratching or damaging the mirror surface.

- Adjustable Power: Customizable laser strength ensures the removal of paint of varying thicknesses, offering versatility in applications.

- Efficiency: Significantly reduces time compared to traditional paint removal methods, making it ideal for large projects.

5️⃣ Benefits for Mirror Applications 🔑

- Full Transparency: Achieves a clear, transparent effect by completely removing the paint from the back of the mirror.

- Versatile Use: Ideal for decorative purposes, repairs, or even repurposing old mirrors.

- Cost-Effective: Significantly reduces labor and material costs compared to traditional paint removal methods.

6️⃣ Request a Demo Today! 📝

Contact us today to learn more about our Laser Paint Stripping Machine or request a demo of our advanced laser paint removal solution. See how our technology can enhance your mirror restoration or industrial applications!

Machine structure | Gantry type |

Working size | 600*900mm |

Servo drive system | uses bus absolute values, and the precise position of the servo motor can be recorded even if the servo motor is unexpectedly powered off or stopped. |

Transmission system (XYZ) | Ball screw and guide rail |

Laser output power | 100W |

Laser type | Fiber Laser |

F-theta lens range | 110*110mm |

Cooling system | Air cooling |

Laser Q-switched frequency | 2KHz-4000KHz |

Machine power | 4000W |

Minimum line width | 0.01mm |

Repeat positioning accuracy | ±0.02mm |

Working power supply | AC 220V/50Hz |

7️⃣Applications of Laser Paint Stripping Machine 💡

Our Laser Paint Stripping Machine is perfect for a wide range of applications, offering precision, efficiency, and eco-friendly solutions for various industries:

- Mirror Paint Removal: Achieve total transparency by stripping paint from the back of mirrors, perfect for creative or functional purposes such as decorative projects, restoration, or repurposing old mirrors.

- Surface Restoration: Remove rust, coatings, or contaminants from metal surfaces, restoring them to their original condition for further treatment or reuse.

- Industrial Cleaning: Prepare surfaces for welding, bonding, or painting, ensuring a smooth, clean base for optimal adhesion and finished results.

8️⃣ FAQ – 600x900mm Mirror Laser Paint Stripping Machine ❓

Q1: What is the maximum size of the mirror that can be processed with this machine?

A1: The 600x900mm Mirror Laser Paint Stripping Machine is designed to handle mirrors up to 600mm x 900mm in size, making it ideal for medium to large mirrors used in commercial and industrial applications.

Q2: How does the laser paint stripping process work on mirrors?

A2: The laser beam targets the paint layer on the back of the mirror without coming into contact with the glass, ensuring total transparency while preserving the integrity of the mirror surface.

Q3: Is the machine environmentally friendly?

A3: Yes! Our Laser Paint Stripping Machine is chemical-free and dust-free, making it an eco-friendly solution for paint removal. There are no harmful chemicals or abrasives used in the process.

Q4: How long does it take to remove paint from a mirror?

A4: The process is incredibly efficient. Paint removal time depends on the paint thickness and mirror size, but typically, the machine can complete the job faster than traditional methods, significantly reducing labor time.

Q5: Can the machine be used for other materials besides mirrors?

A5: Absolutely! While it’s optimized for mirror paint removal, the 600x900mm Laser Paint Stripping Machine is versatile enough to strip paint from various materials, including metal, glass, and more, for industrial cleaning and surface restoration.

Q6: Is the machine easy to operate?

A6: Yes! The user-friendly interface and adjustable laser settings make operation simple and straightforward. Even those without prior experience can quickly learn how to use the machine effectively.

Q7: What maintenance is required for the machine?

A7: The machine requires minimal maintenance. Regular cleaning of the laser lens and checking the settings are recommended. We also provide customer support for any issues or troubleshooting.

Q8: Can I get a demo of the machine before purchasing?

A8: Yes! We offer live demos of the 600x900mm Laser Paint Stripping Machine. Contact us today to schedule a demo and see the machine in action!

Mirror paint removing videos

Request a Quote for a Large format Laser Marking Machine

SISMAR LASER has Large format laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality large format laser marking machine that exceeds your expectations. You can also schedule a demo to see how large format laser marking machine laser marking works

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- EZCAD common errorMarch 18, 2025 - 2:09 am

- Small Business Guide: Navigating the Evolving 3D Crystal Engraving Market in 2025March 12, 2025 - 5:31 am

- “Continuous vs. Pulsed Laser Cleaning: Single Mode vs. Multi Mode LasersFebruary 21, 2025 - 5:54 am

- “Laser precision, zero damage—cleaning rust and paint without harming your product.”February 21, 2025 - 3:08 am

- Why Choose glass laser drilling machineJanuary 31, 2025 - 4:59 am