Лазерный очиститель с импульсным лазером мощностью 200 Вт и 300 Вт

April 3, 2025 /0 Comments/in Language /by linda

Лазерный очиститель с импульсным лазером мощностью 200 Вт и 300 Вт

Безопасная очистка без химикатов для сложных и деликатных поверхностей

Импульсный волоконно-лазерный очиститель – точность, безопасность и эффективность

Наш импульсный волоконно-лазерный очиститель, доступный в моделях мощностью 100 Вт, 200 Вт и 300 Вт, использует передовую импульсную лазерную технологию для удаления ржавчины, краски, масла, покрытий и загрязнений с металлических и неметаллических поверхностей. В отличие от непрерывных лазерных систем, он подает контролируемые импульсы энергии, предотвращая повреждение поверхности и обеспечивая отсутствие вреда для материала.

С компактным, портативным и ручным дизайном этот лазерный очиститель легко переносится и используется в различных условиях. Он идеально подходит для отраслей, требующих высокоточной очистки без химикатов или абразивов, обеспечивая экологически чистые, быстрые и эффективные результаты.

Будь то удаление ржавчины или восстановление поверхности, наш лазерный очиститель ржавчины помогает поддерживать качество продукции и способствует росту бизнеса.

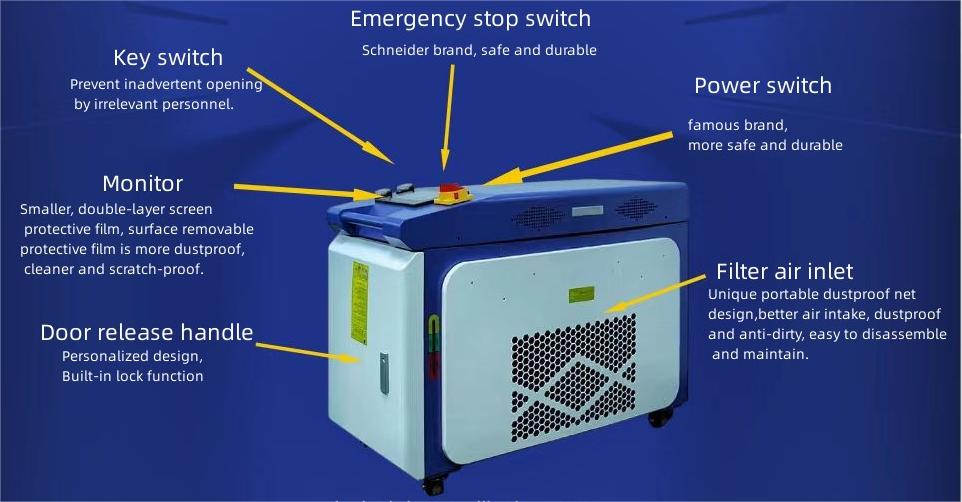

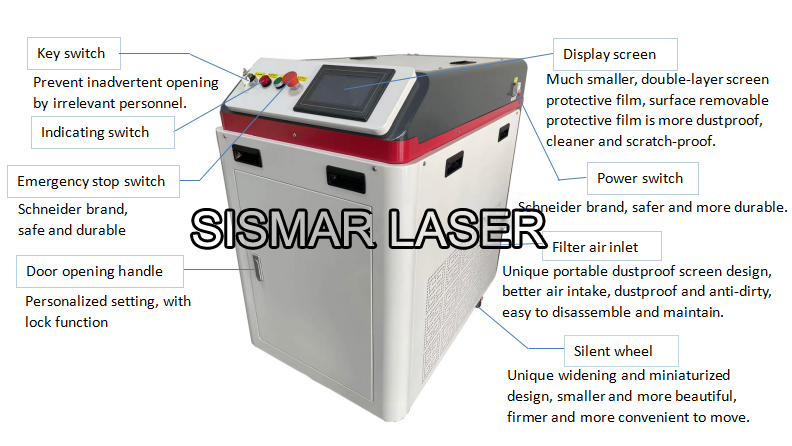

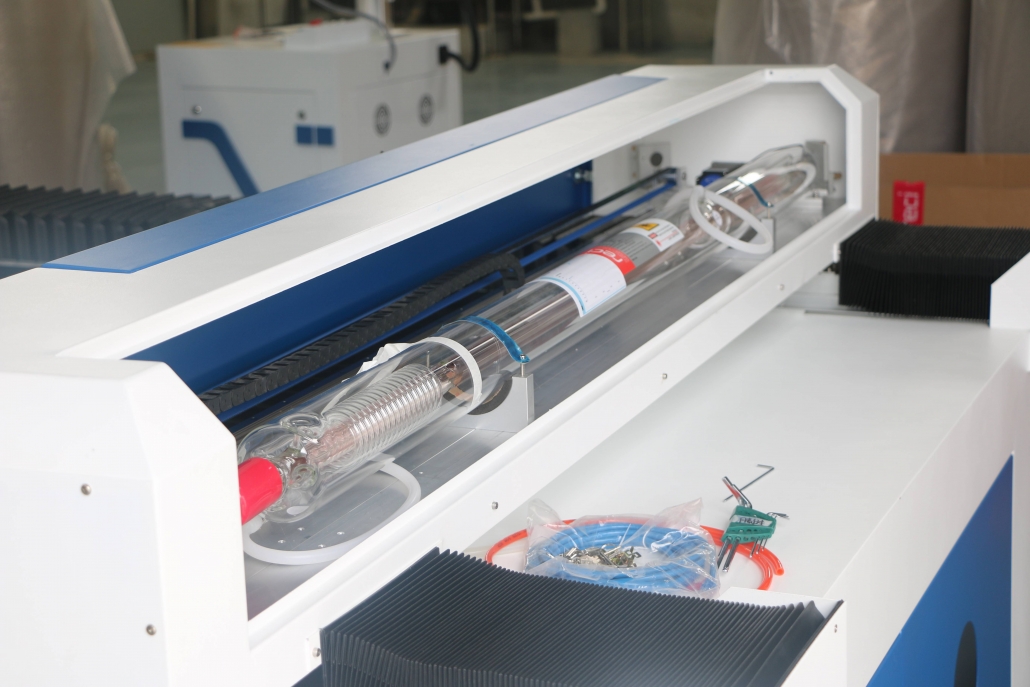

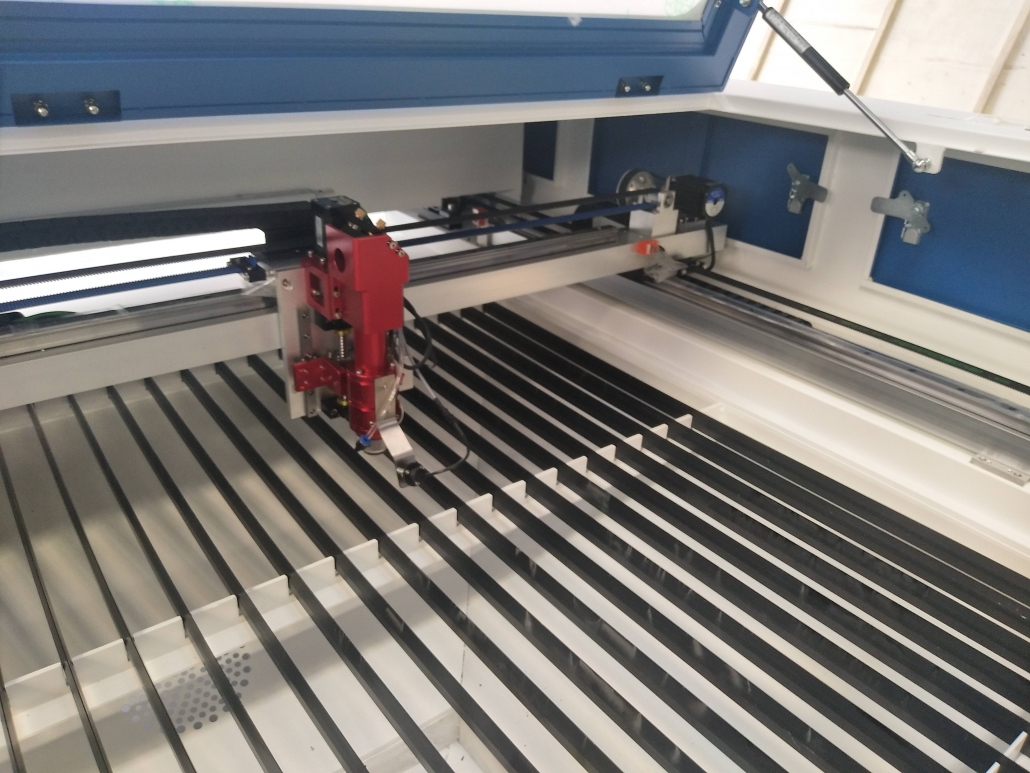

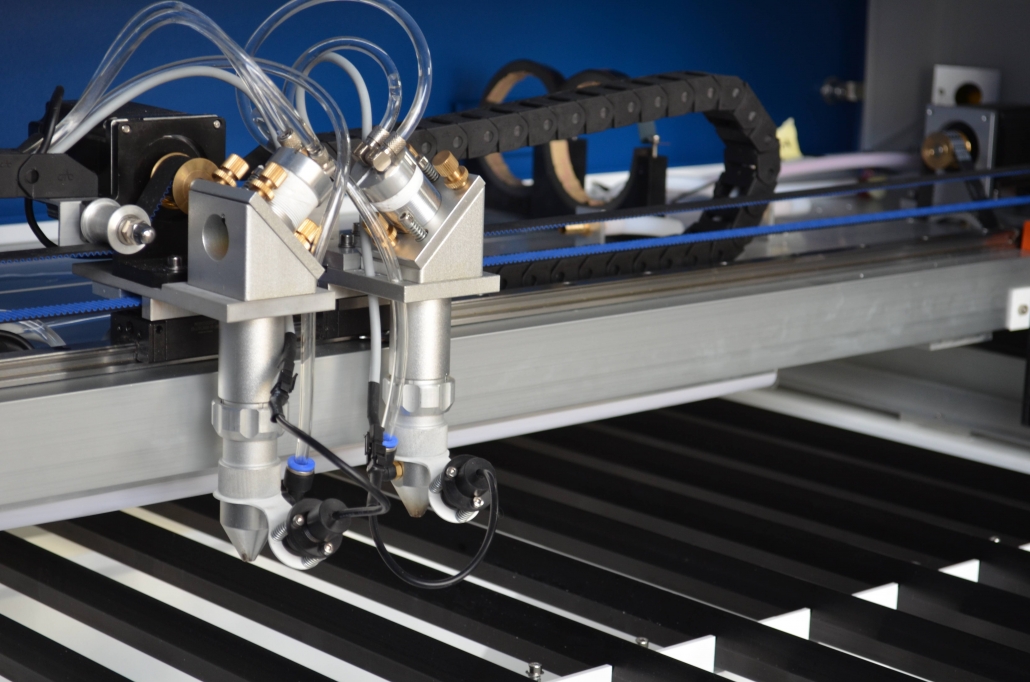

Фотографии машины импульсного лазерного очистителя

Портативный волоконно-лазерный очиститель SISMAR LASER с импульсным лазером: точность, отсутствие повреждений и превосходное решение для очистки

В промышленном производстве чистота поверхности — это не просто вопрос внешнего вида, а фактор, напрямую влияющий на качество и долговечность продукции. Традиционные методы очистки часто заставляют вас выбирать между эффективностью и риском: химическая очистка ведет к загрязнению, а механическая — может повредить деликатные поверхности. Вы когда-нибудь сталкивались с трудностью найти решение, которое обеспечивает и эффективность, и безопасность при удалении упорной ржавчины или краски?

Портативный волоконно-лазерный очиститель SISMAR LASER с импульсным лазером решает эти проблемы.

1. Проблемы, с которыми вы сталкиваетесь:

-

Вам нужно удалить стойкую краску и ржавчину, но вы боитесь повредить точные компоненты или основной цвет.

-

Вам нужна очистка без следов, особенно на сложных деталях, где даже малейшая царапина или повреждение могут повлиять на производительность.

-

Традиционные методы с использованием химикатов или высокого давления могут оставить вторичное загрязнение или увеличить пост-обработочные расходы.

2. Решение:

Портативный волоконно-лазерный очиститель SISMAR LASER с импульсным лазером использует высокоэффективные импульсные лазерные лучи для точного удаления загрязнителей с поверхности, включая краску, ржавчину и мусор, без необходимости в химикатах или физическом контакте. Благодаря коротким и интенсивным лазерным импульсам, он мгновенно испаряет загрязнения, оставляя основной цвет нетронутым и обеспечивая высокую точность очистки. Каждый сеанс очистки — это как деликатное восстановление поверхности изделия, а не жесткая шлифовка. Идеально подходит для высокоточных компонентов, электроники и даже произведений искусства.

С технологией лазерной очистки SISMAR LASER с импульсным лазером вы можете:

Особенности | Описание

-

Полное удаление загрязнителей | Даже самая стойкая ржавчина и краска не составляют проблемы.

-

Сохранение целостности поверхности | Точное управление энергией лазера предотвращает повреждение основного цвета или деликатных конструктивных элементов.

-

Эффективность и экологичность | Без химикатов и высококачественного давления воды — избегая загрязнения и дополнительных расходов на пост-обработку.

-

Широкие возможности применения | Независимо от того, работаете ли вы с сталью, алюминиевыми сплавами, электронными компонентами или произведениями искусства, SISMAR LASER предлагает идеальное решение.

Не позволяйте традиционным методам очистки ограничивать вас. Выберите портативный волоконно-лазерный очиститель SISMAR LASER с импульсным лазером и дайте каждой детали сиять точностью, качеством и эффективностью.

Что вам нужно — это не просто чистота, а совершенство без компромиссов. Попробуйте портативный волоконно-лазерный очиститель SISMAR LASER с импульсным лазером сегодня и сделайте очистку более эффективной, точной и экологичной.

3. Параметры лазерного очистителя с импульсным лазером

Параметры ручного лазерного удалителя ржавчины

| Модель | SL-C200/300 |

|---|---|

| Мощность лазера | 200W/300W |

| Рабочее напряжение | 110/220V 50/60 HZ |

| Режим работы лазера | Импульс |

| Лазерный источник | JPT |

| Средняя мощность лазера | >300W |

| Нестабильность мощности | <5% |

| Максимальная энергия импульса | 15mJ |

| Длительность импульса | 2-500нс |

| Метод охлаждения | Водяное охлаждение |

| Диапазон регулировки мощности (%) | 0-100 (градуируемый) |

| Частота повторения (кГц) | 1-4000 (градуируемая) |

| Длина волоконного кабеля | 5м |

| Вес очистной головки (включая изолятор) | <1,5кг |

| Влажность рабочего окружения | ≤80% |

| Температура рабочего окружения | 10℃~40℃ |

| Размеры машины (длина, ширина, высота) | Примерно 860мм410мм700мм |

| Вес машины | Примерно 80кг |

Параметры лазерной очистной головки

| Характеристика | Параметр |

|---|---|

| Вес очистной головки | Менее 1,25кг |

| Ширина сканирования | 0-145мм (опционально) |

| Частота сканирования | Не менее 300Гц |

| Максимальная скорость сканирования | Примерно 30м/с |

| Максимальная скорость сканирования | 20000мм/с |

| Пропускная способность света | ≥98% |

| Регулировка мощности лазера | 10%-100% |

| Фокусное расстояние | Стандартная конфигурация 210мм (опционально 160мм/254мм/330мм/420мм) |

| Диаметр пятна света | ≤10мм |

| Длина кабеля | Стандартная конфигурация 10м |

🚀 1️⃣ Почему импульсный волоконно-лазерный очиститель — это будущее очистки поверхностей

Устали от методов очистки, которые слишком жестоки для вашего оборудования или не дают нужных результатов? Традиционные методы очистки — такие как химические вещества, абразивы или высокое давление — могут повредить ваши изделия и привести к дорогостоящим ремонтам. Если вам нужно эффективное, экологичное и точное решение, то импульсный волоконно-лазерный очиститель — это то, что вам нужно.

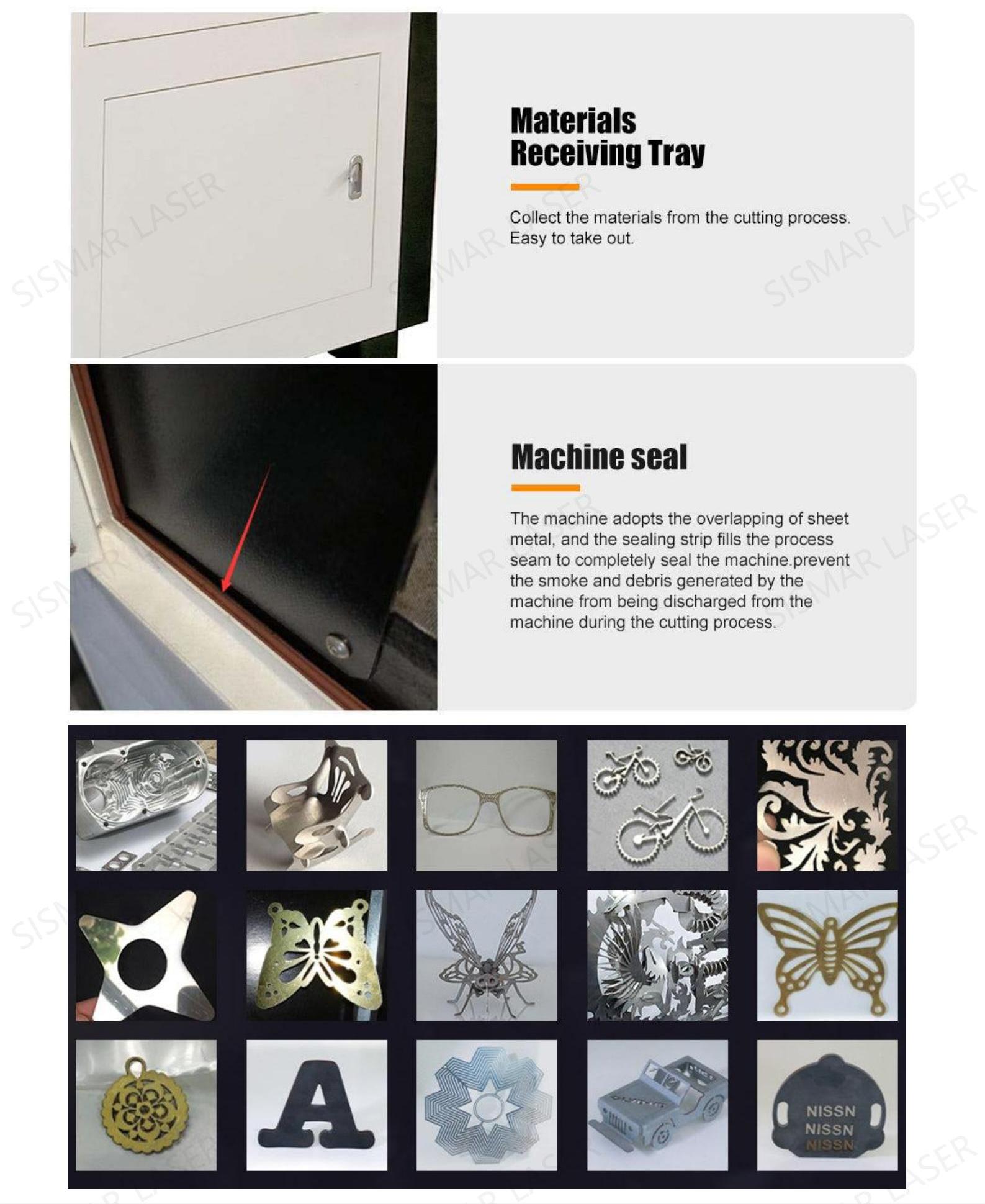

Эта передовая технология революционизирует способ очистки поверхностей в различных отраслях. От удаления ржавчины до снятия покрытий, импульсная лазерная очистка предлагает безопасный, эффективный и экологически чистый способ очистки различных материалов. Давайте подробнее рассмотрим, как эта мощная машина может принести пользу ключевым отраслям.

✨ 2️⃣ Основные применения импульсного волоконно-лазерного очистителя

⚙️ 2.1 Удаление ржавчины и окислов в металлургической промышленности

Ржавчина и окисление — частая проблема в отраслях, работающих с металлическими компонентами. Импульсный волоконно-лазерный очиститель быстро удаляет коррозию, не повреждая основную поверхность, гарантируя, что ваши материалы останутся целыми и готовыми к использованию. Это особенно важно для автомобильного производства, строительства и обработки металлов, где высокое качество материалов имеет решающее значение.

Преимущества:

-

Быстрое и эффективное удаление ржавчины

-

Сохранение целостности материала

-

Без химических веществ и абразивных материалов

⚡ 2.2 Удаление краски и покрытий в автомобильной и аэрокосмической промышленности

Импульсный волоконно-лазерный очиститель идеально подходит для удаления краски, покрытий и клеевых материалов без повреждения деликатных поверхностей. В таких отраслях, как автомобильное производство и аэрокосмическая промышленность, точное удаление краски необходимо для подготовки деталей к финишной отделке или дальнейшей обработке.

Преимущества:

-

Удаляет краску и покрытия с лазерной точностью

-

Без риска повреждения сложных частей

-

Экологически чистое решение, без вредных химикатов

💻 2.3 Подготовка поверхностей для электроники

Когда речь идет об очистке электронных компонентов, таких как печатные платы или деликатные части, импульсный волоконно-лазерный очиститель предлагает решение без контакта. Способность лазера очищать без физического контакта гарантирует, что чувствительные компоненты не будут повреждены, что делает его идеальным для производства электроники.

Преимущества:

-

Без контакта, сохраняет деликатные компоненты

-

Точная очистка без повреждений

-

Идеально подходит для мелких, сложных поверхностей

🔧 2.4 Очистка форм и пресс-форм в производстве

Для отраслей, занимающихся литьем пластмасс или металлов, важно поддерживать формы и пресс-формы в чистоте. Импульсный волоконно-лазерный очиститель легко удаляет остатки резины, металла или пластика, не вызывая износа, продлевая срок службы ваших форм и пресс-форм.

Преимущества:

-

Быстро и эффективно удаляет загрязнения

-

Без абразивных материалов, сохраняя качество форм

-

Повышает эффективность за счет сокращения времени простоя

🏺 2.5 Восстановление исторических артефактов в музеях и консервации искусств

Нежная, но эффективная природа импульсной лазерной очистки делает её идеальным решением для очистки деликатных исторических артефактов. Будь то удаление сажи с雕塑ов или ржавчины с металлических объектов, эта технология помогает сохранить и восстановить предметы искусства и музейные экспонаты.

Преимущества:

-

Безопасно для деликатных и бесценных предметов

-

Бережная очистка сохраняет историческую ценность

-

Экологически чистое решение, без химических веществ

🔥 3️⃣ Почему стоит выбрать импульсный волоконно-лазерный очиститель?

Импульсный волоконно-лазерный очиститель — это не просто еще один инструмент для очистки — это революционное решение. В отличие от традиционных методов, он предлагает несколько неоспоримых преимуществ:

-

Точность: Лазерная очистка гарантирует, что каждая поверхность будет обработана точно так, как нужно, без повреждения материала.

-

Эффективность: Вы можете удалить ржавчину, покрытия и загрязнения быстрее, чем когда-либо.

-

Экологичность: Нет необходимости в агрессивных химикатах или растворителях, что делает это решение экологически чистым.

-

Экономичность: Снижается потребность в ручном труде, абразивных инструментах и дорогих химикатах, что экономит деньги в долгосрочной перспективе.

💡 4️⃣ Поднимите процесс очистки на новый уровень

Будь вы в металлургическом производстве, автомобильной промышленности или производстве электроники, импульсный волоконно-лазерный очиститель предлагает передовое, надежное и экологичное решение для ваших нужд в очистке. Избегая проблем традиционных методов и предлагая точность и эффективность, эта машина изменит подход к очистке поверхностей в различных отраслях.

Готовы испытать будущее очистки? Выберите импульсный волоконно-лазерный очиститель и обеспечьте, чтобы ваше оборудование оставалось в отличном состоянии, с минимальным воздействием на окружающую среду и максимальной эффективностью.

FAQ – Импульсный волоконно-лазерный очиститель

-

Как работает импульсный волоконно-лазерный очиститель?

Ответ:

Импульсный волоконно-лазерный очиститель использует короткие высокоэнергетические лазерные импульсы для интенсивного воздействия на загрязнители поверхности, такие как ржавчина, краска и окислы. Лазерная энергия вызывает испарение или фрагментацию этих загрязнителей почти мгновенно. Этот метод очистки без контакта эффективно удаляет поверхностные загрязнения без повреждения основного материала. Лазерная очистка не только быстрая и эффективная, но и не приводит к химическому загрязнению.

-

Как часто необходимо проводить техническое обслуживание импульсного волоконно-лазерного очистителя?

Ответ:

Обычно цикл технического обслуживания для импульсного волоконно-лазерного очистителя составляет от 6 месяцев до 1 года. Точное расписание обслуживания зависит от частоты использования и условий эксплуатации. Регулярное обслуживание включает проверку оптоволоконных кабелей, лазерного источника, системы охлаждения и контрольных систем для обеспечения нормальной работы. Рекомендуется регулярно чистить внутреннюю часть машины и поддерживать лазерный выходной порт в чистоте для оптимальной работы.

-

Какие материалы подходят для очистки с помощью импульсного волоконно-лазерного очистителя?

Ответ:

Импульсный волоконно-лазерный очиститель подходит для широкого спектра материалов, особенно для металлов. Общие материалы включают:

-

Сталь, алюминиевые сплавы, медь и другие: удаление ржавчины, краски, окислов и других загрязнений.

-

Пластики и резина: очистка поверхностных загрязнений или старых покрытий.

-

Прецизионные электронные компоненты: очистка без контакта для предотвращения повреждения деликатных структур.

-

Искусство и исторические артефакты: бережная очистка для удаления загрязнений, сохраняя оригинальный вид.

-

Какое влияние лазерная очистка оказывает на поверхности?

Ответ:

Импульсный волоконно-лазерный очиститель оказывает минимальное влияние на поверхности. Поскольку процесс очистки без контакта, он не вызывает физической абразии или царапин. Точное управление лазерными импульсами и мощностью обеспечивает удаление загрязнителей без повреждения основного материала, что делает его идеальным для деликатных и высокоточечных очисток.

-

Является ли лазерная очистка экологически чистым методом?

Ответ:

Да, импульсная лазерная очистка — это экологически чистый метод. В отличие от традиционной химической очистки или очистки с высоким давлением, лазерная очистка не требует химических растворителей и не производит вредных отходов или загрязняющих веществ. Это снижает использование химикатов и предотвращает вторичное загрязнение, соответствуя современным экологически чистым стандартам.

-

Эффективна ли лазерная очистка для всех типов загрязнителей?

Ответ:

Импульсный волоконно-лазерный очиститель высокоэффективен в удалении различных загрязнителей, таких как ржавчина, краска, окислы, грязь, клеи и другие производственные остатки. Однако для некоторых упорных загрязнителей (например, глубоко вмонтированных веществ) может потребоваться несколько сеансов очистки. Мощность и частота лазера могут регулироваться в зависимости от задачи для оптимизации результатов.

-

Сложна ли эксплуатация импульсного волоконно-лазерного очистителя?

Ответ:

Нет, эксплуатация импульсного волоконно-лазерного очистителя проста и интуитивно понятна. Операторы могут управлять машиной через сенсорный экран или компьютерное ПО. Процесс очистки можно выполнить в автоматическом режиме, что снижает потребность в специализированных навыках. Большинство лазерных машин также оснащены функциями безопасности для обеспечения безопасной работы во время очистки.

-

Какова скорость очистки импульсного волоконно-лазерного очистителя?

Ответ:

Скорость очистки импульсного волоконно-лазерного очистителя невероятно высокая — обычно машина способна очистить несколько квадратных метров в минуту, в зависимости от типа загрязнителей и состояния поверхности. Для легких загрязнений скорость очистки выше; для более стойких пятен может потребоваться больше времени, но лазерная очистка все равно остается намного более эффективной по сравнению с традиционными методами.

-

Требуется ли специальная рабочая среда для лазерной очистки?

Ответ:

Импульсный волоконно-лазерный очиститель адаптирован для работы в разных условиях, но для обеспечения оптимальной работы лучше использовать его в хорошо вентилируемой среде с умеренной температурой. Избегайте экстремальной влажности или высоких температур. Большинство машин оснащены системами охлаждения, чтобы поддерживать устройство в подходящем температурном диапазоне.

-

Каков срок службы импульсного волоконно-лазерного очистителя?

Ответ:

Импульсный волоконно-лазерный очиститель обычно служит более 10 лет. Срок службы зависит от факторов, таких как частота использования, условия эксплуатации и регулярное техническое обслуживание. При правильном уходе и своевременном ремонте лазерная очистка может поддерживать свою высокую эффективность и продолжать обеспечивать надежную работу на протяжении долгого времени.

Эти часто задаваемые вопросы помогут вам лучше понять импульсный волоконно-лазерный очиститель, его преимущества и как он может улучшить ваш процесс очистки. Независимо от того, в какой отрасли вы работаете — автомобильной, производственной или электронной, эта машина предлагает высокопроизводительное, экологичное решение для ваших потребностей в очистке.

Рабочее видео импульсного волоконно-лазерного очистителя

Запросить коммерческое предложение на лазерную очистительную машину

SISMAR LASER предлагает лазерные очистительные машины и другие решения для различных промышленных приложений. Наши решения могут стать обновлением вашей существующей системы лазерной очистки или отличным выбором для вашей первой лазерной машины.

Запросите коммерческое предложение на высококачественную лазерную очистку, которая превзойдет ваши ожидания. Вы также можете назначить демонстрацию, чтобы увидеть, как работает эколо-гически чистая лазерная очистка.

Добро пожаловать в SISMAR LASER! Мы рады ответить на все ваши вопросы о наших волоконно-лазерных машинах для маркировки, резки и сварки.