Machine de marquage laser à fibre grand format

March 25, 2025 /0 Comments/in Language /by linda

Machines de marquage laser grand format | Solutions de marquage de précision à l'échelle industrielle

Marquage haute vitesse pour pièces surdimensionnées | Zone de travail personnalisable jusqu'à 3000x1500mm

Machines de Marquage Laser Grand Format | Déverrouillez des Possibilités Illimitées

Vous avez du mal avec un espace de marquage limité ? Nos machines de marquage laser grand format sont la solution que vous attendiez. Conçues pour des opérations à grande échelle, ces machines brisent les contraintes des systèmes traditionnels grâce à leur système de mouvement avancé sur les axes XY. Avec des bancs de travail personnalisables, vous pouvez marquer sur des surfaces de toutes tailles — fini les préoccupations concernant les zones inaccessibles.

Le système de marquage de suivi révolutionnaire garantit que votre processus de marquage soit fluide et continu, même lorsque la machine est en mouvement. Cela signifie des temps de production plus rapides sans compromis sur la qualité. Que vous soyez dans l’automobile, l’aérospatiale ou toute autre industrie exigeant une grande précision, ces machines offrent la performance nécessaire pour rester en tête.

Prêt à faire passer vos capacités de marquage au niveau supérieur ? Nos machines allient puissance et flexibilité, garantissant des résultats parfaits à chaque fois.

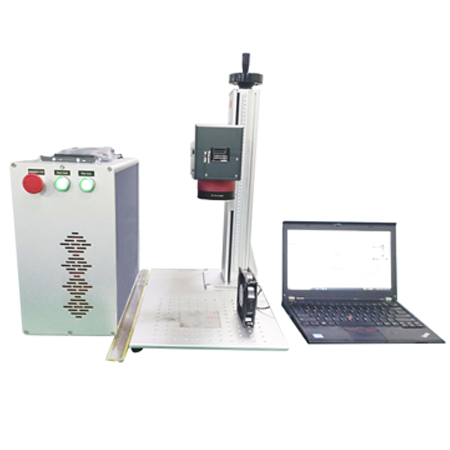

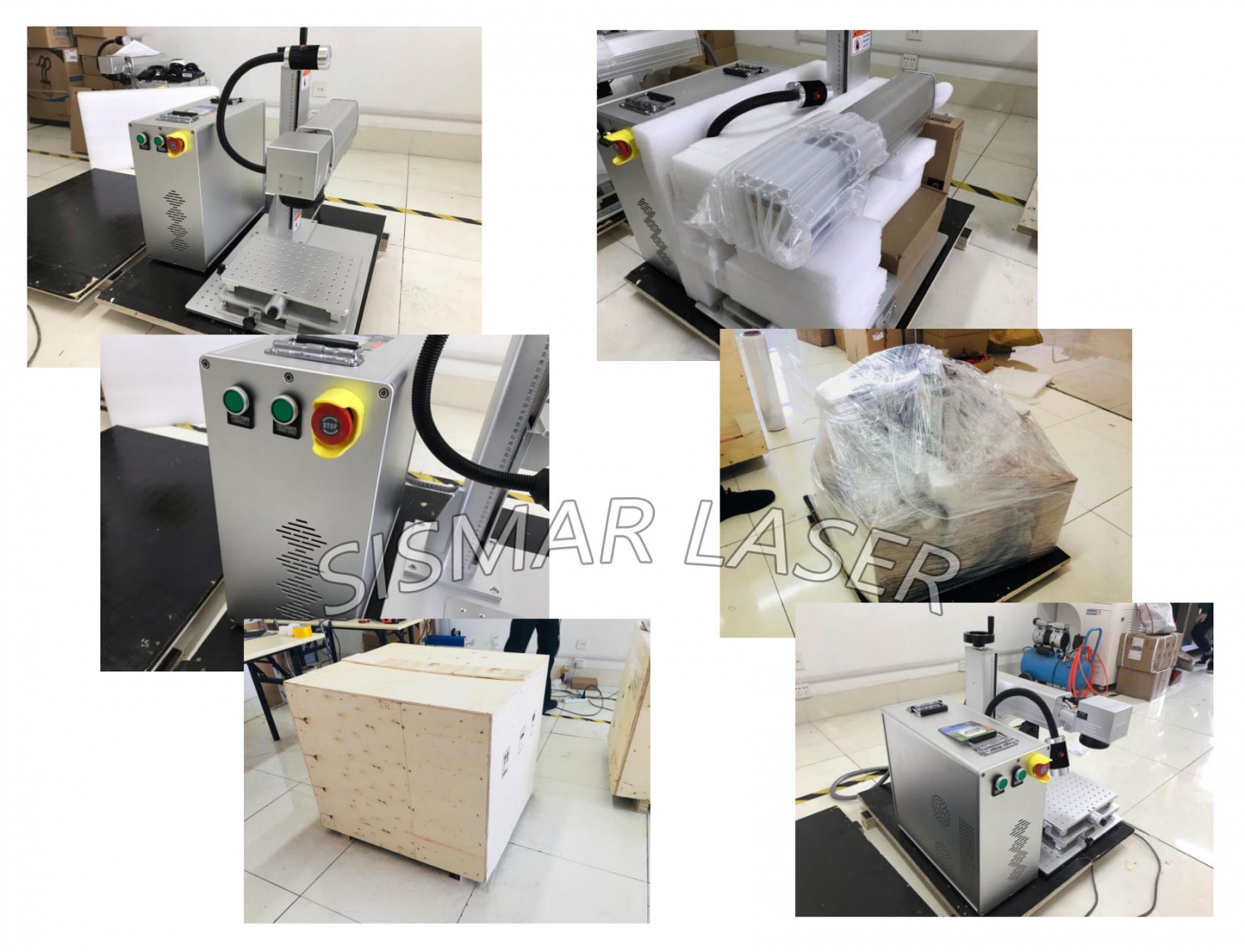

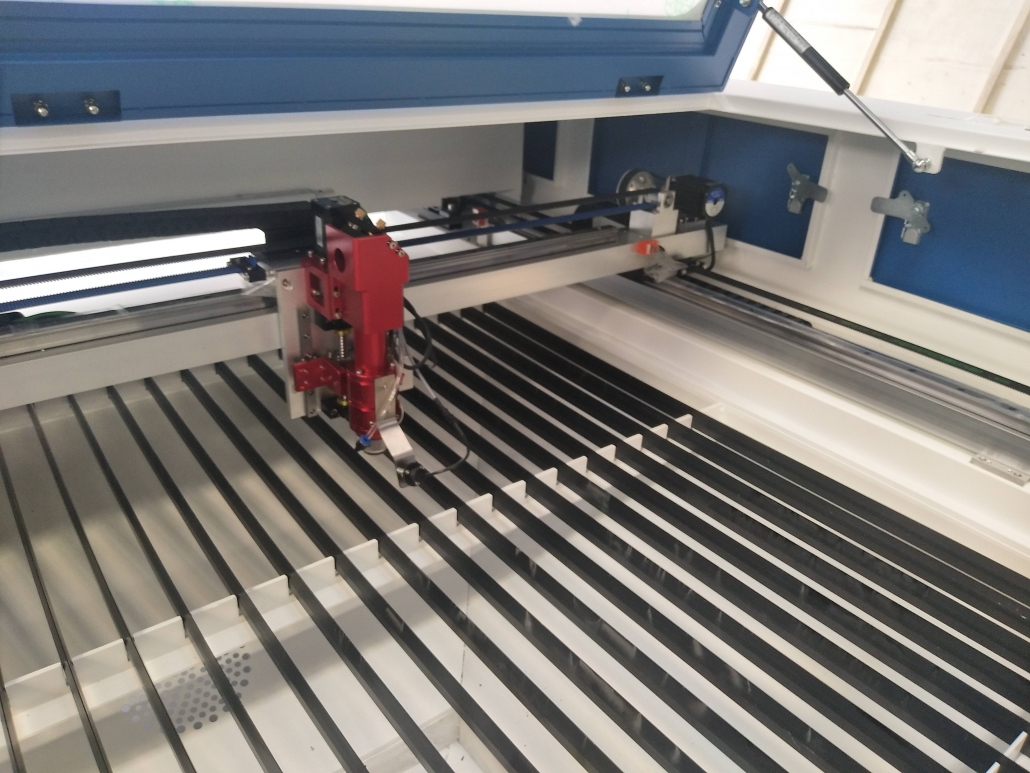

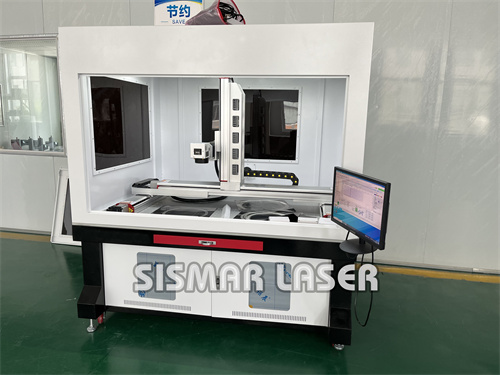

Photos des Machines de Marquage Laser Grand Format

Machines de Marquage Laser Grande Taille Type Gantry | Précision et Efficacité pour la Production à Grande Échelle ✨

Nos Machines de Marquage Laser Grande Taille Type Gantry sont spécialement conçues pour les applications de production de grande taille et de production en série. Avec des tailles standard de 600×600 mm et 1300×2500 mm, nous proposons également des options personnalisables pour répondre à vos besoins spécifiques.

Vous souhaitez amener votre marquage grand format au niveau supérieur ? Nos Machines de Marquage Laser Grande Taille sont la solution ultime pour les entreprises ayant besoin de précision, de vitesse et de polyvalence—sans aucune des limitations habituelles. Ces machines sont dotées de nombreuses fonctionnalités qui facilitent les opérations à grande échelle, accélèrent la production et augmentent l’efficacité.

1. Tables de Travail Personnalisables—Vos Projets, à Votre Façon 🛠️

Fini de travailler dans des limites restrictives. Avec nos Machines de Marquage Laser Grande Taille, vous pouvez personnaliser la table de travail pour s’adapter à des pièces de toutes tailles. Cela signifie plus de contraintes, plus de configurations maladroites. Vous obtenez la flexibilité pour gérer tout, des composants massifs aux pièces plus petites et détaillées—sans compromettre la qualité.

2. Système de Mouvement XY-Axe—Déplacez-vous avec Précision 🎯

La précision est essentielle dans le marquage au laser. Notre système de mouvement XY-Axe avancé garantit un mouvement fluide et précis sur de grandes surfaces, vous offrant des résultats impeccables et consistants à chaque fois. Que vous marquiez des designs complexes, des numéros de série ou des logos, vous pouvez compter sur des marques nettes et claires qui résistent à l’épreuve du temps.

3. Système de Marquage Suivant—Marquez en Mouvement 🚀

Voici la révolution : notre système de marquage suivant vous permet de marquer pendant que la machine est en mouvement. Cela signifie que vous pouvez réduire le temps d’arrêt, maintenir la machine en fonctionnement continu et réaliser des tâches à haut volume plus rapidement que jamais—sans compromettre la qualité de vos marques.

4. Conçu pour Toutes les Industries, Tous les Matériaux 🔧

Que vous soyez dans l’automobile, l’aérospatiale, l’électronique ou tout autre secteur, nos machines sont conçues pour travailler sur une large gamme de matériaux, y compris les métaux, les plastiques, les céramiques et bien plus encore. Graver des numéros de série ? C’est fait. Des logos ou des codes-barres ? Aucun problème. Des motifs complexes ou des designs intriqués ? Facile. Avec notre technologie de marquage laser, vous pouvez tout gérer avec facilité et précision.

5. Durable et Peu Entretien 🛠️

Ces machines sont conçues pour durer—prêtes à supporter même les environnements les plus exigeants. Avec des besoins d’entretien minimes et une construction robuste, nos Machines de Marquage Laser Grande Taille continueront à travailler pendant des années, vous permettant de vous concentrer sur ce qui compte : accomplir votre travail.

Pourquoi Choisir Nos Machines de Marquage Laser Grande Taille ? 🤔

-

Tables de Travail Personnalisables : Ajustez la taille pour tout type de pièce, grande ou petite.

-

Mouvement XY-Axe Avancé : Profitez de mouvements fluides et précis pour des marquages parfaits.

-

Système de Marquage Suivant : Marquez en mouvement pour maximiser la vitesse de production.

-

Compatibilité Matériaux Polyvalente : Idéale pour les métaux, les plastiques, les céramiques et plus.

-

Conçu pour la Production à Haut Volume : Design robuste, entretien minimal, et performance fiable.

Voici une détail des paramètres pour une Machine de Marquage Laser Grande Taille avec différents types de lasers : Laser UV, Laser Fibre et Laser CO₂.

1. Laser Fibre

-

Longueur d’onde : Environ 1064 nm, idéal pour le marquage des métaux.

-

Puissance : Généralement entre 20W et 100W, selon les exigences de l’application.

-

Vitesse de marquage : Peut atteindre jusqu’à 7000 mm/s, convenant à la production en grande série.

-

Taille minimale des caractères : Aussi petite que 0,15 mm, garantissant des détails fins dans les marquages.

-

Système de refroidissement : Refroidissement par air couramment utilisé, réduisant les coûts de maintenance.

2. Laser UV

-

Longueur d’onde : Environ 355 nm, parfait pour un marquage précis sur les matériaux non métalliques.

-

Puissance : Généralement entre 3W et 20W, conçu pour un marquage de haute précision.

-

Vitesse de marquage : Modérée, selon le matériau et l’application.

-

Taille minimale des caractères : Aussi petite que 0,05 mm, idéal pour les tâches de haute précision.

-

Système de refroidissement : Le refroidissement par eau est souvent utilisé pour garantir un fonctionnement stable pendant une utilisation prolongée.

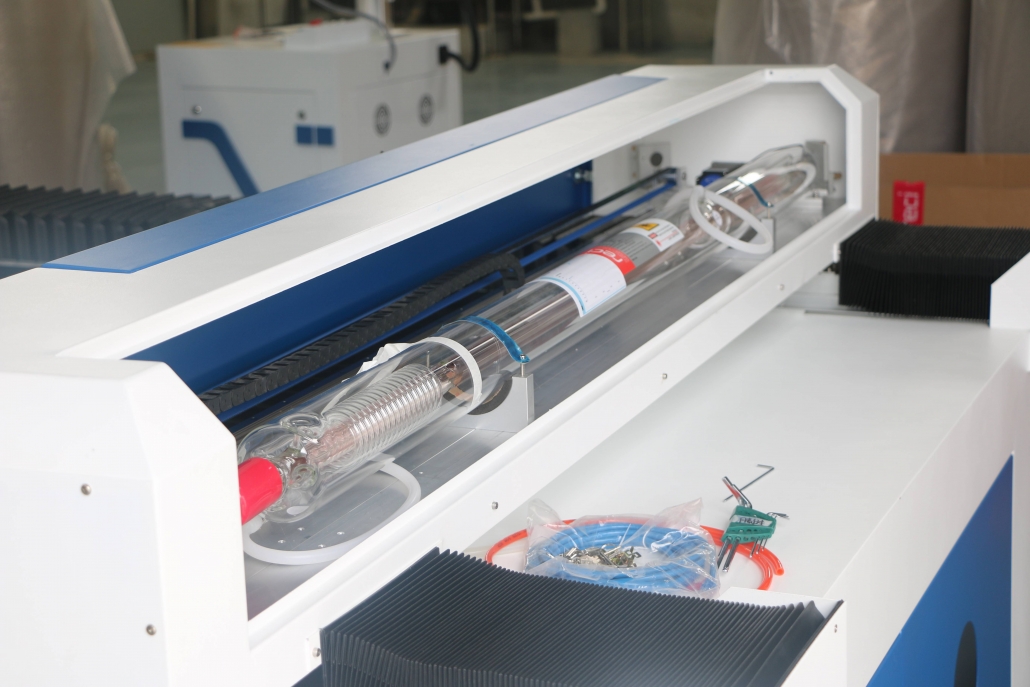

3. Laser CO₂

-

Longueur d’onde : Environ 10600 nm, adapté au marquage et découpe des matériaux non métalliques.

-

Puissance : Généralement entre 30W et 60W, adaptable à une variété de matériaux.

-

Vitesse de marquage : Modérée, selon le matériau et la complexité du marquage.

-

Taille minimale des caractères : Aussi petite que 0,1 mm, convenant aux exigences de précision générale.

-

Système de refroidissement : Utilise souvent soit l’air, soit l’eau en fonction de la conception de la machine et des besoins en puissance.

Conclusion :

Ces paramètres fournissent une orientation générale, mais les spécifications réelles peuvent varier en fonction du modèle de machine et du fabricant. Lors de la sélection du type de laser pour vos besoins de marquage, tenez compte des propriétés des matériaux et des exigences de l’application pour garantir des performances optimales et des résultats de qualité.

Machines de Marquage Laser Grande Taille | La polyvalence rencontre la précision à travers les industries

La Machine de Marquage Laser Grande Taille est une véritable révolution pour les industries nécessitant un marquage précis, efficace et de haute qualité sur de grandes surfaces. Avec la flexibilité de travailler avec différents types de lasers—lasers à fibre, lasers UV, et lasers CO₂—cette machine peut traiter une large gamme de matériaux, ce qui la rend adaptable à pratiquement tous les environnements de production. Que vous marquiez du métal, du verre, du plastique ou du bois, cette machine polyvalente garantit précision et durabilité. Voici comment elle fonctionne avec divers matériaux et industries :

Lasers à Fibre : Précision pour les Métaux et les Équipements Industriels

Les lasers à fibre sont connus pour leur efficacité et leur précision, notamment lorsqu’il s’agit de travailler avec des métaux. Ces lasers sont parfaits pour les applications nécessitant des marquages de haute définition qui résistent à des environnements difficiles.

-

Acier inoxydable : Parfait pour graver des numéros de série, des codes-barres, et des logos sur des surfaces en acier inoxydable. Idéal pour des industries telles que l’aérospatiale, l’automobile et les équipements médicaux, où une identification claire et durable est essentielle.

-

Aluminium et autres métaux : Les lasers à fibre marquent efficacement des matériaux comme l’aluminium, le laiton, et le titane, ce qui les rend hautement adaptés aux industries de l’automobile, de l’électronique, et de l’aérospatiale, où des marquages fins et permanents sont cruciaux.

Lasers UV : Précision sur le Verre et les Plastiques

Les lasers UV offrent des marquages fins et à contraste élevé, particulièrement sur des matériaux délicats comme le verre et les plastiques. Ces lasers sont connus pour leur capacité à créer des marquages précis sans endommager ni fissurer les surfaces sensibles.

-

Verre : Les lasers UV excellent dans le marquage des surfaces en verre sans compromettre le matériau. Ils sont utilisés dans des industries telles que la boisson, les cosmétiques, et la pharmaceutique pour marquer des bouteilles, des conteneurs, et des produits en verre.

-

Plastiques : Que ce soit pour des dispositifs électroniques, des appareils médicaux, ou des produits de consommation, les lasers UV offrent des marquages durables et lisibles sur une gamme de plastiques, ce qui les rend parfaits pour des produits nécessitant clarté et longévité.

Lasers CO₂ : Idéal pour les Matériaux Organiques

Les lasers CO₂ sont très efficaces pour découper et graver des matériaux organiques comme le cuir, le bois, et l’acrylique. Ces lasers offrent des coupes et des gravures précises avec un minimum de dommage au matériau, ce qui les rend parfaits pour diverses applications de conception et de fabrication.

-

Cuir : Idéal pour graver et découper des produits en cuir tels que des sacs, des chaussures, et des accessoires. Les lasers CO₂ garantissent des designs complexes et des bords nets sans endommager le matériau.

-

Bois et acrylique : Que vous créiez des enseignes personnalisées, des meubles, ou des pièces décoratives, les lasers CO₂ fournissent des marquages et des découpes précises pour le bois et l’acrylique, parfaits pour des industries telles que l’aménagement intérieur, la publicité, et l’artisanat.

Applications à Travers les Industries :

Grâce à son adaptabilité à différents types de lasers, la Machine de Marquage Laser Grande Taille sert une large gamme d’industries, améliorant ainsi la précision, la vitesse, et l’efficacité. Voici de plus près ses applications dans divers secteurs :

-

Fabrication Industrielle

-

Automobile : Gravage de composants, de pièces et d’outils de grande taille, garantissant la traçabilité et l’identification avec un marquage rapide pour les grandes séries de production.

-

Aérospatiale : Fournit des marquages permanents et précis sur les composants aérospatiaux pour répondre aux normes de sécurité et de qualité, assurant ainsi la conformité réglementaire.

-

-

Électronique de Consommation

-

Marquage Électronique : Marque des logos, des numéros de série, et des informations réglementaires sur les appareils et composants électroniques, améliorant l’identification des produits et la reconnaissance de la marque sur le marché mondial.

-

-

Dispositifs Médicaux

-

Marquage Précis pour Instruments Médicaux : Garantit des marquages permanents et précis sur les outils et équipements médicaux, en respectant des exigences réglementaires strictes pour la traçabilité, la stérilisation et la sécurité.

-

-

Industrie de l’Emballage

-

Marquage d’Emballages : Du carton au plastique et au verre, cette machine marque les numéros de lot, les codes-barres, et les informations produit sur les matériaux d’emballage, rationalisant la gestion des stocks et assurant un suivi précis.

-

-

Art et Design

-

Designs Personnalisés : Que ce soit pour graver des motifs complexes sur du bois, du cuir, ou de l’acrylique, nos machines de marquage laser grande taille répondent aux besoins des artistes, des designers, et des artisans, créant des produits personnalisés de haute qualité pour un usage personnel et commercial.

-

Pourquoi Choisir Nos Machines de Marquage Laser Grande Taille ?

-

Polyvalence Inégalée : Compatible avec les lasers à fibre, UV, et CO₂, cette machine peut marquer sur des matériaux tels que métaux, plastiques, verre, cuir, et plus encore—idéale pour des industries avec des besoins de matériaux divers.

-

Précision à Grande Échelle : Que vous marquiez de grandes surfaces ou des détails complexes, la machine fournit des marques hautement précises et permanentes à chaque fois.

-

Vitesse et Efficacité : Conçue pour une production en grande série, elle augmente la productivité tout en maintenant une qualité de marquage exceptionnelle, même sur de grandes pièces.

-

Rentable : La machine de marquage laser grande taille offre une fiabilité à long terme, une maintenance minimale et des coûts opérationnels faibles, vous offrant ainsi plus de valeur pour votre investissement.

Prêt à Améliorer Votre Ligne de Production ?

Des composants industriels aux produits de consommation, la machine de marquage laser grande taille est la solution incontournable pour la précision, la vitesse, et la polyvalence. Quelle que soit votre industrie, cette machine peut vous aider à rationaliser vos opérations, à améliorer la reconnaissance de la marque, et à optimiser la traçabilité. Prêt à amener votre processus de production au niveau supérieur ? Contactez-nous dès aujourd’hui pour en savoir plus !

Questions Fréquemment Posées (FAQ)

1️⃣ Qu’est-ce qu’une machine de marquage laser grande taille ? Une machine de marquage laser grande taille est un système laser spécialisé conçu pour marquer et graver de grands objets ou matériaux avec une grande précision. Ces machines sont idéales pour le traitement de composants de grande taille, tels que des pièces industrielles, des enseignes, des emballages volumineux, et plus encore. Contrairement aux systèmes laser plus petits, ces machines peuvent gérer des applications à grande échelle, offrant flexibilité et polyvalence dans diverses industries.

2️⃣ Quels matériaux la machine de marquage laser grande taille peut-elle traiter ? La machine de marquage laser grande taille est capable de travailler avec une variété de matériaux, y compris :

-

Métaux (acier, aluminium, laiton, etc.)

-

Plastiques

-

Bois

-

Acrylique

-

Cuir

-

Verre

-

Céramique

-

Textiles

-

Caoutchouc

Cela en fait un excellent choix pour des industries telles que l’automobile, l’électronique, la construction, la publicité, l’architecture, et la fabrication de panneaux.

3️⃣ Quelle est la zone de marquage de la machine de marquage laser grande taille ? La machine de marquage laser grande taille peut couvrir une zone de marquage bien plus grande par rapport aux machines laser standard. Les zones de marquage typiques varient de 500 mm x 500 mm à 2000 mm x 2000 mm ou plus, selon le modèle. Cette zone étendue permet de travailler avec des produits de grande taille sans avoir besoin de plusieurs configurations.

4️⃣ La machine de marquage laser grande taille est-elle équipée d’un système mobile ou non mobile ? La machine de marquage laser grande taille est disponible avec deux types de systèmes :

-

Système mobile (Galvo) : Dans ce système, la tête laser se déplace sur la surface de marquage tandis que le matériau reste stationnaire. Cela est généralement plus rapide et plus précis, ce qui le rend idéal pour des conceptions complexes et de grande taille.

-

Système non mobile (Cartésien) : Dans ce système, le matériau se déplace sous une tête laser fixe. Il est souvent utilisé pour des objets plus grands et plus lourds, offrant plus de polyvalence pour le traitement des matériaux.

Les deux systèmes sont conçus pour fournir de la précision, le système mobile étant plus rapide et le système non mobile offrant plus de flexibilité pour les objets lourds et encombrants.

5️⃣ Quelles industries bénéficient de l’utilisation de la machine de marquage laser grande taille ? La machine de marquage laser grande taille est très bénéfique pour les industries qui nécessitent un marquage et un gravage sur de grandes surfaces. Certaines des industries qui utilisent ces machines incluent :

-

Automobile (marquage de grandes pièces, châssis et composants)

-

Construction (gravure de grandes enseignes et composants architecturaux)

-

Fabrication de panneaux (création de grandes enseignes personnalisées, plaques et affichages)

-

Aérospatiale (gravure de numéros de série, logos et identification de pièces)

-

Emballage (marquage de matériaux d’emballage ou de contenants volumineux)

-

Fabrication (marquage de produits de grande taille ou d’équipements industriels)

-

Art et sculpture (gravure de grandes œuvres d’art ou sculptures)

6️⃣ Comment la machine de marquage laser grande taille garantit-elle la précision ? La machine de marquage laser grande taille maintient une haute précision grâce à des systèmes de scannage galvo avancés et des ajustements de mise au point automatiques. L’utilisation d’optique de haute résolution et de mouvements contrôlés par ordinateur assure que même les grandes surfaces reçoivent des marquages nets et détaillés. De nombreux modèles incluent également des lasers d’alignement pour un réglage facile et un contrôle automatique de la mise au point pour une profondeur constante.

7️⃣ La machine de marquage laser grande taille est-elle facile à utiliser ? Oui, la plupart des machines de marquage laser grande taille sont équipées d’un logiciel convivial qui facilite la conception et la configuration des projets, même pour les débutants. L’interface intuitive de la machine permet de télécharger des designs, d’ajuster les paramètres et d’opérer le système avec une formation minimale. Les modèles avancés peuvent offrir des fonctionnalités telles que l’importation automatique de fichiers, le traitement par lots et la surveillance en temps réel pour simplifier encore davantage le processus.

8️⃣ Quelles sont les options de puissance disponibles pour la machine de marquage laser grande taille ? La machine de marquage laser grande taille est disponible avec différentes options de puissance, généralement comprises entre 20 W et 500 W ou plus, selon les besoins spécifiques de l’application. Les lasers plus puissants conviennent mieux aux gravures profondes, à la découpe de matériaux plus durs ou au traitement de grandes quantités de travail. Le choix de la puissance permet une flexibilité pour répondre aux exigences des applications de marquage, qu’il s’agisse de détails fins ou de marquage et découpe sur de grandes surfaces.

9️⃣ Quelle maintenance est nécessaire pour la machine de marquage laser grande taille ? La maintenance est relativement minime, mais il est essentiel de :

-

Nettoyer régulièrement les lentilles et les miroirs pour éviter l’accumulation et maintenir une performance optimale.

-

Vérifier l’alignement du système pour garantir une précision de marquage constante sur les grandes surfaces.

-

Surveiller le système de refroidissement pour éviter la surchauffe, surtout pour les modèles haute puissance.

-

Inspecter la source laser périodiquement et la remplacer si nécessaire.

-

Garder les rails et les gantries de la machine exempts de débris pour un fonctionnement fluide.

🔟 Quels types de produits la machine de marquage laser grande taille peut-elle traiter ? La machine de marquage laser grande taille peut traiter une large gamme de tailles de produits, des petits objets aux composants de grande taille. La zone de marquage étendue (jusqu’à 2000 mm x 2000 mm) permet à la machine de traiter des articles volumineux tels que des pièces industrielles, des enseignes, des meubles et des œuvres d’art personnalisées, ce qui la rend idéale pour les industries avec des produits encombrants.

1️⃣1️⃣ La machine de marquage laser grande taille peut-elle être intégrée à une ligne de production automatisée ? Oui, de nombreuses machines de marquage laser grande taille peuvent être intégrées à des systèmes automatisés, tels que des convoyeurs, des robots ou des lignes de montage. Cela les rend idéales pour les industries nécessitant une production continue et rapide avec marquage et gravage automatisés. Le système peut être synchronisé avec des systèmes de contrôle de mouvement, garantissant un flux de travail fluide.

1️⃣2️⃣ Quel est le prix des machines de marquage laser grande taille ? Le prix de la machine de marquage laser grande taille varie en fonction de facteurs tels que la puissance laser, la zone de marquage et les fonctionnalités supplémentaires. En général, les prix vont de 10 000 $ pour les modèles à faible puissance à plus de 100 000 $ pour les systèmes haut de gamme avec des fonctionnalités avancées et de grandes zones de marquage. Le prix dépend de votre application spécifique et du niveau de précision et de puissance que vous requérez.

Vidéo de fonctionnement de la machine de marquage laser grande taille

Demandez un devis pour une machine de marquage laser grande taille

SISMAR LASER propose des machines de marquage laser grande taille ainsi que d’autres solutions pour de nombreuses applications industrielles. Nos solutions peuvent servir à mettre à niveau votre système de marquage laser existant ou être un excellent choix pour votre première machine laser.

Demandez un devis pour une machine de marquage laser grande taille de haute qualité qui dépasse vos attentes. Vous pouvez également planifier une démonstration pour voir comment fonctionne le marquage laser grande taille.

Bienvenue chez SISMAR LASER. Nous sommes ravis de répondre à toutes vos questions concernant nos machines de marquage/coupe laser à fibre.