Máquina de Gravação a Laser para Hobby

March 7, 2025 /0 Comments/in Language /by linda

Máquina de Gravação e Corte a Laser CO2 para Hobby 400*600mm

🎨 Liberte Seu Potencial Criativo com Nossa Máquina de Gravação e Corte a Laser para Hobby! 🚀

Quer transformar suas ideias em realidade? Nossa Máquina de Gravação e Corte a Laser para Hobby é a ferramenta perfeita para criativos, artesãos e pequenos negócios. Com alta precisão e versatilidade, você pode trabalhar com madeira, acrílico, couro e muito mais! Seja para criar presentes personalizados, itens exclusivos ou protótipos inovadores, esta máquina compacta e fácil de usar está pronta para dar vida às suas criações.

🔥 Principais Benefícios:

✅ Compatibilidade com Diversos Materiais – Grave e corte com facilidade em vários tipos de superfícies.

✅ Compacta e Acessível – Ideal para oficinas domésticas e pequenos espaços.

✅ Alta Precisão – Crie designs detalhados e intrincados com máxima qualidade.

✅ Fácil de Usar – Controles intuitivos e software amigável, perfeito para iniciantes.

✨ Dê vida às suas ideias criativas com nossa Máquina de Gravação e Corte a Laser para Hobby! ✨

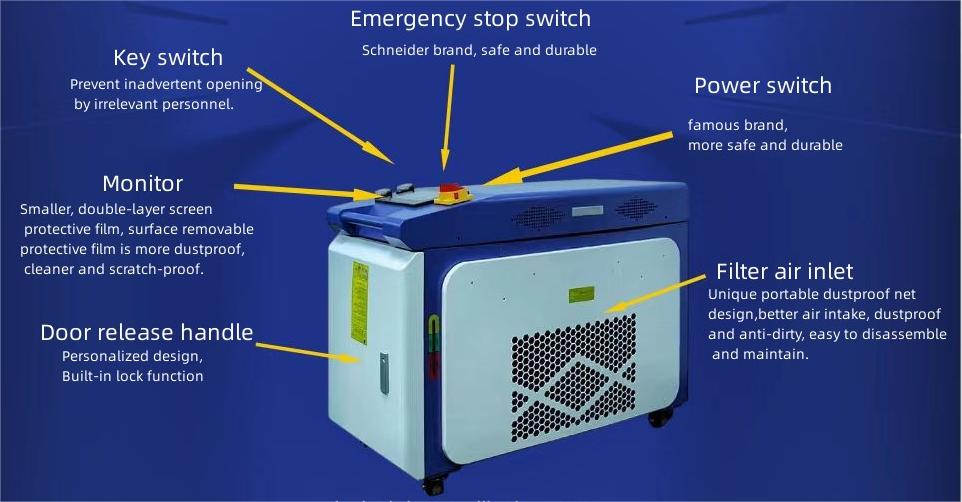

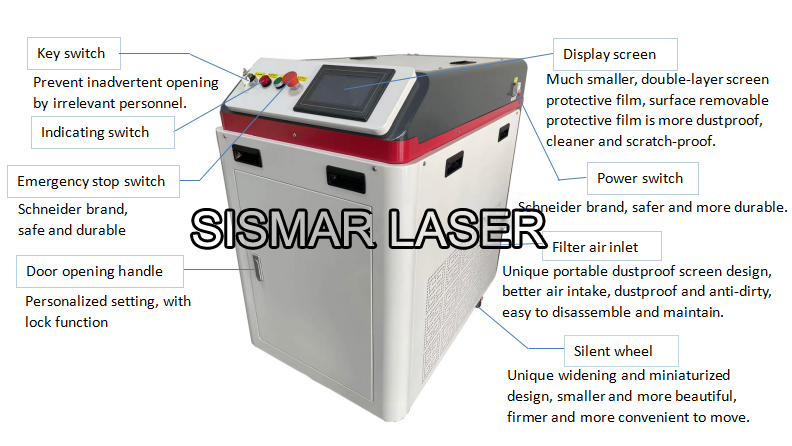

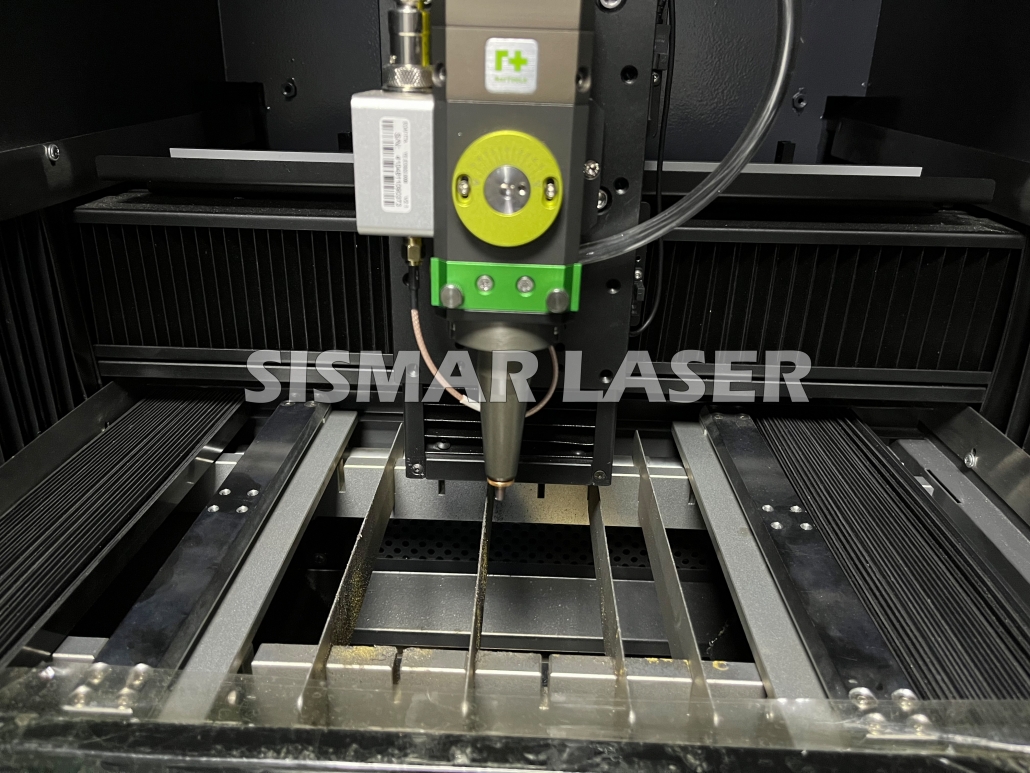

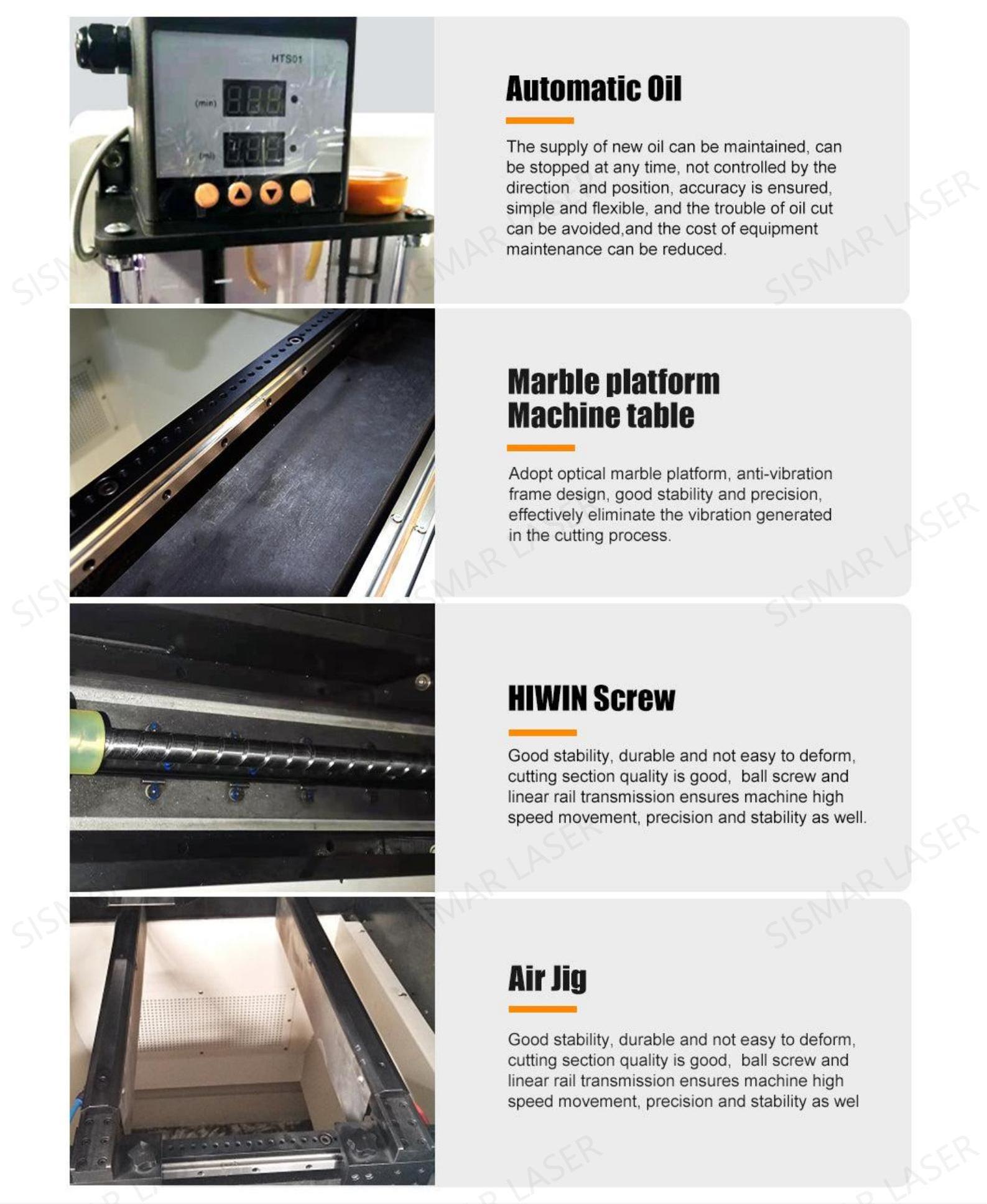

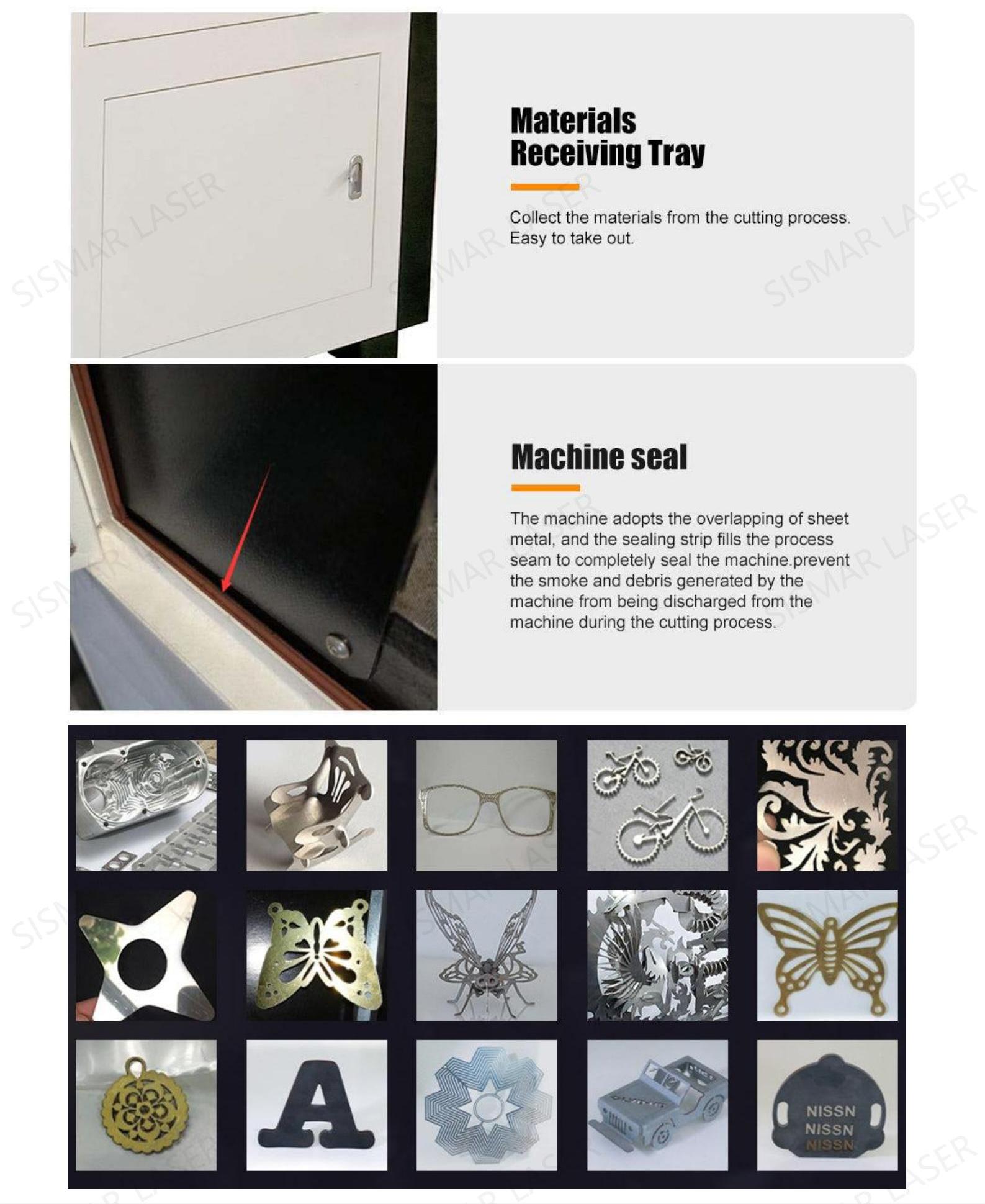

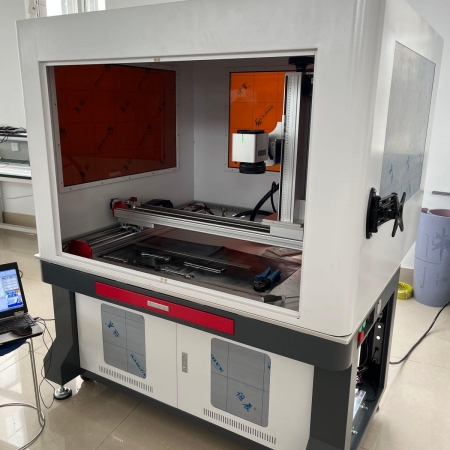

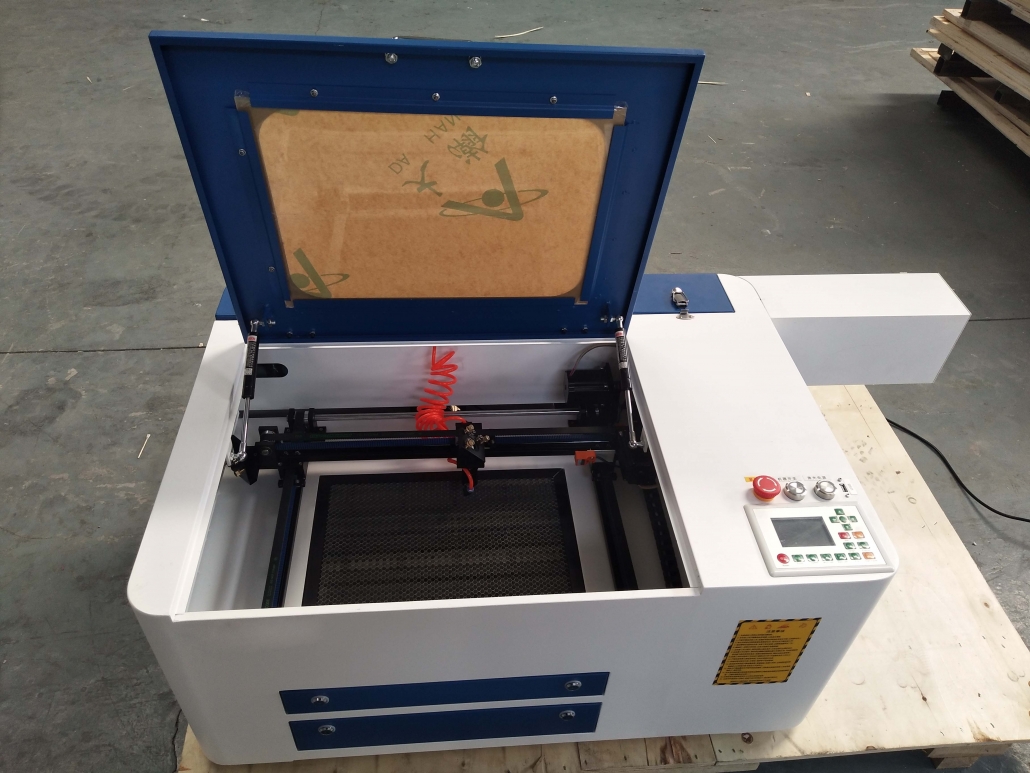

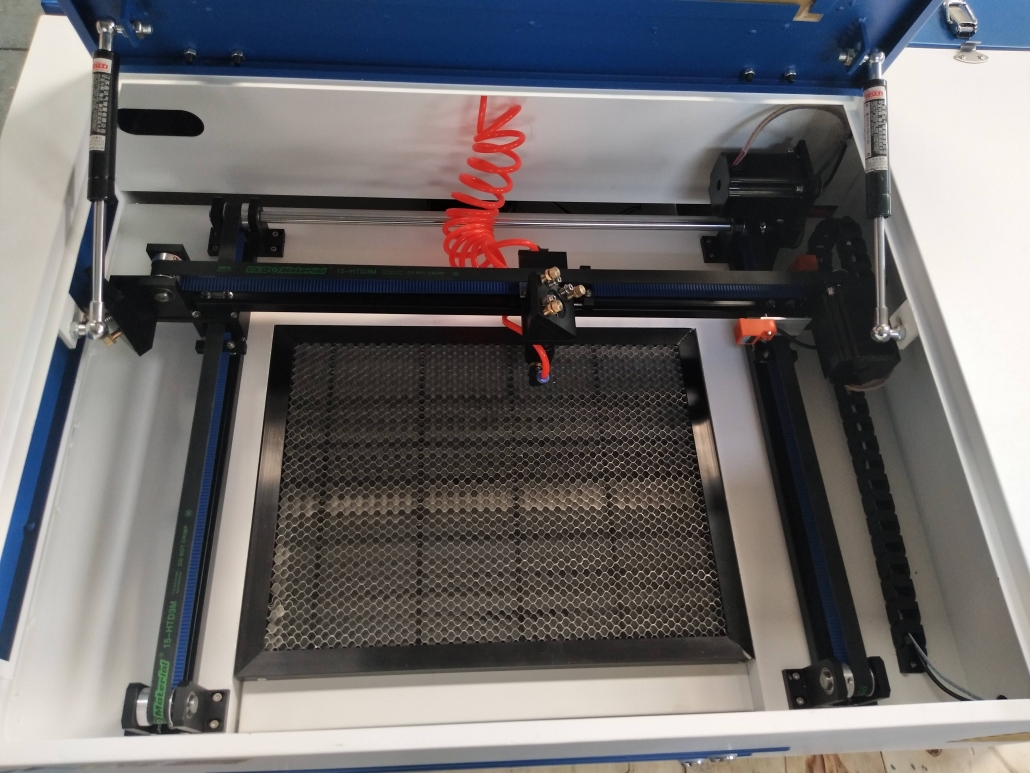

Fotos da Máquina de Gravação e Corte a Laser CO₂ para Hobby 400*600mm

🚀 Desperte Sua Criatividade com Nossa Máquina de Gravação e Corte a Laser CO₂!

Você está pronto para levar seus projetos DIY para o próximo nível? A Máquina de Gravação e Corte a Laser CO₂ é exatamente o que você precisa. Seja você um hobbista, empreendedor de um pequeno negócio ou um entusiasta criativo, este equipamento transforma suas ideias em realidade com precisão e facilidade. De cortes intricados em madeira e acrílico à gravação de mensagens personalizadas em couro, esta ferramenta versátil é perfeita para uma ampla variedade de materiais.

1️⃣ Principais Características da Nossa Máquina de Gravação e Corte a Laser CO₂

| # | Características | Descrição |

|---|---|---|

| 1 | Alta Precisão | Alcance designs impressionantes e intrincados com a precisão que somente um laser CO₂ pode oferecer. Ideal para trabalhos detalhados em madeira, plástico, couro e mais. |

| 2 | Compatibilidade com Vários Materiais | Desde madeira até acrílico, vidro e couro, nossa máquina de corte a laser CO₂ lida com diversos materiais, sendo indispensável para artesanato, produção de pequenos negócios e muito mais. |

| 3 | Eficiência & Custo-Benefício | Economize tempo e dinheiro com uma máquina que consome menos energia enquanto oferece velocidades rápidas de gravação e corte, maximizando a produtividade e reduzindo custos. |

| 4 | Interface Amigável | Se você é novo no mundo da gravação a laser, não se preocupe! Este equipamento vem com um painel de controle intuitivo e software fácil de usar, facilitando o início imediato. |

| 5 | Durável & Longa Vida Útil | Projetada para uso contínuo, nossa máquina de gravação a laser CO₂ garante desempenho confiável e mínimo tempo de inatividade, permitindo que você foque no que mais importa: suas criações. |

2️⃣ Por Que Escolher uma Máquina de Gravação e Corte a Laser CO₂?

Seja para artesanato, produção em pequena escala ou para personalizar presentes, a Máquina de Gravação e Corte a Laser CO₂ vai transformar o seu fluxo de trabalho. Este equipamento oferece cortes e gravações com precisão inigualável, permitindo que você crie designs complexos com detalhes incríveis. Sua versatilidade permite trabalhar com vários materiais, sendo ideal para aplicações como confecção de letreiros, gravuras em joias, presentes personalizados e muito mais.

Além disso, a máquina é econômica, operando com baixa potência e entregando resultados rápidos. Se você procura uma solução acessível de gravação e corte a laser que não comprometa a qualidade, esta é a escolha perfeita.

3️⃣ Perfeita para Pequenos Negócios e Entusiastas DIY

Se você é dono de um pequeno negócio, um hobbista ou um entusiasta do faça você mesmo, esta máquina de corte a laser CO₂ vai economizar tempo e dinheiro. Seu design compacto se encaixa em pequenos espaços, enquanto o laser de alta potência garante que o trabalho seja realizado de forma rápida e eficiente. E o melhor: sua operação simples significa que você não precisa ser um expert para obter resultados impressionantes!

4️⃣ Pronto para Elevar Seus Projetos Criativos?

Comece hoje mesmo com nossa Máquina de Gravação e Corte a Laser CO₂ e desbloqueie possibilidades infinitas para designs personalizados, presentes exclusivos e produtos com qualidade profissional. Seja cortando padrões intricados em madeira ou gravando a sua marca em vidro, esta máquina é a solução ideal para transformar suas ideias em realidade.

💡 Transforme seu processo criativo e dê vida aos seus projetos com precisão, eficiência e estilo!

Agende uma demonstração ou solicite um orçamento agora mesmo e veja como a nossa tecnologia pode revolucionar o seu mundo criativo! 🚀✨

📌 Especificações da Máquina de Gravação e Corte a Laser CO₂

| Categoria | Especificação |

|---|---|

| 📏 Área de Gravação | 600mm x 400mm |

| 📐 Dimensões da Máquina | 1300mm x 815mm x 420mm |

| ⚖️ Peso | 100KG |

🔥 Especificações do Laser

| Categoria | Especificação |

|---|---|

| ✅ Tipo de Laser | Tubo Laser CO₂ Selado |

| ✅ Potência do Laser | 40W / 60W |

⚙️ Especificações do Sistema

| Categoria | Especificação |

|---|---|

| 🚀 Sistema de Movimentação | Stepper |

| 💦 Modo de Resfriamento | Sistema de resfriamento por recirculação de água com proteção |

| 🌡️ Temperatura de Operação | 0 – 45ºC |

🎁 Acompanha Gratuitamente

| Categoria | Especificação |

|---|---|

| 💻 Processador | DSP + USB |

| 🖥️ Software | Laserwork |

| 🔳 Mesa de Trabalho | Blade Worktable |

| 💧 Bomba de Água | Bomba de água básica |

| 🌬️ Exaustor | Ventilador de exaustão básico |

🛠️ Garantia

| Categoria | Especificação |

|---|---|

| 📜 Peças/Mão de Obra | Garantia limitada de 1 ano (exclui frete e itens consumíveis) |

⚡ Adquira já a sua máquina de gravação e corte a laser CO₂ e leve seus projetos a um novo nível de precisão e eficiência! 🚀

📌 Aplicações da Máquina de Gravação e Corte a Laser CO₂ para Hobby

🌟 Liberte sua criatividade com a Máquina de Gravação e Corte a Laser CO₂! Seja você um entusiasta do DIY, um pequeno empresário ou um criador apaixonado, este equipamento permite transformar suas ideias mais ambiciosas em realidade. Confira as incríveis aplicações abaixo:

1️⃣ 🎁 Presentes Personalizados Que Encantam

✅ Grave designs exclusivos em madeira, vidro, acrílico e couro.

✅ Crie presentes únicos e inesquecíveis, feitos sob medida.

✅ Personalize com nomes, datas e mensagens especiais para momentos marcantes.

2️⃣ 💍 Design e Personalização de Joias

✅ Transforme materiais como madeira, acrílico e metal em joias incríveis.

✅ Desenvolva padrões detalhados e gravações personalizadas.

✅ Ideal para anéis, colares e pulseiras com toques exclusivos.

3️⃣ 🪑 Marcenaria e Criação de Obras Artesanais

✅ Cortes precisos para projetos de marcenaria como placas, móveis e decorações.

✅ Gravação detalhada em madeira para economizar tempo e aprimorar a criatividade.

✅ Perfeito para criar peças decorativas ou móveis personalizados.

4️⃣ 👛 Gravação e Corte em Couro para Criações Únicas

✅ Personalize carteiras, cintos, chaveiros e muito mais.

✅ Desenvolva padrões complexos e sofisticados para tornar cada peça especial.

✅ Ideal para artesãos e produção de artigos de luxo personalizados.

5️⃣ 🏗️ Modelagem e Protótipos com Precisão

✅ Corte e grave com alta precisão para modelos, protótipos e maquetes arquitetônicas.

✅ Produza modelos detalhados para design e arquitetura.

✅ Resultados impecáveis que transformam ideias em realidade profissional.

6️⃣ 🖼️ Criação de Placas e Identidade Visual

✅ Produza placas personalizadas, logotipos e sinalizações para empresas.

✅ Gravações precisas para um acabamento profissional e impactante.

✅ Realce a identidade da sua marca com designs únicos e sofisticados.

7️⃣ 🎓 Projetos Educacionais e DIY Sem Complicação

✅ Transforme projetos escolares e modelos educativos com gravação a laser.

✅ Crie expositores interativos, estênceis e materiais de aprendizado.

✅ Incentive a criatividade e o aprendizado prático com projetos envolventes.

8️⃣ 📦 Design de Embalagens Inovadoras

✅ Personalize embalagens de acrílico, papelão e madeira com gravações exclusivas.

✅ Ideal para embalagens personalizadas de produtos, presentes e muito mais.

✅ Destaque sua marca com logotipos e mensagens diferenciadas nas embalagens.

🎯 Por que Escolher a Máquina de Gravação e Corte a Laser CO₂ para Hobby?

🔹 Precisão excepcional para cortes e gravações detalhadas.

🔹 Versatilidade incomparável para diversas aplicações e materiais.

🔹 Fácil de usar, perfeito para iniciantes e profissionais.

🔹 Aprimore seu negócio ou hobby com resultados incríveis.

🚀 Pronto para transformar suas ideias em realidade? Comece hoje mesmo! 🔥

❓ Máquina de Gravação e Corte a Laser CO₂ para Hobby – Perguntas Frequentes (FAQ)

1️⃣ Quais materiais posso gravar e cortar com a Máquina de Gravação e Corte a Laser CO₂ para Hobby?

A máquina pode trabalhar com uma ampla variedade de materiais, incluindo:

✔ Madeira (Compensado, MDF, etc.)

✔ Acrílico

✔ Couro

✔ Plástico

✔ Vidro

✔ Papelão

✔ Tecido

✔ Borracha (para carimbos)

✔ Papel

Essa versatilidade permite criar desde presentes personalizados até produtos para negócios com alta qualidade.

2️⃣ Qual a precisão da gravação e do corte?

A Máquina de Gravação e Corte a Laser CO₂ para Hobby oferece altíssima precisão, perfeita para designs detalhados. Seja para logotipos personalizados ou cortes complexos, o equipamento garante resultados consistentes e de nível profissional.

3️⃣ Iniciantes conseguem usar essa máquina?

✅ Sim! A máquina foi projetada para ser fácil de usar, com um painel de controle intuitivo e um software simplificado.

✅ Inclui um manual completo e tutoriais para um aprendizado rápido.

✅ Tanto iniciantes quanto profissionais podem operar a máquina sem dificuldades.

4️⃣ Qual é a área máxima de gravação e corte?

🛠️ A área de trabalho é de 600mm x 400mm, ideal para:

✔ Projetos DIY

✔ Criação de placas personalizadas

✔ Produção de brindes e presentes

✔ Modelagem e prototipagem

Com esse espaço amplo, você pode trabalhar em diversos tamanhos de projeto sem limitações.

5️⃣ A máquina é adequada para pequenos negócios?

✅ Perfeitamente! Com alta eficiência e custo-benefício, esta máquina é uma excelente escolha para empreendedores criativos.

✅ Seu design compacto se encaixa facilmente em oficinas ou pequenos espaços comerciais.

✅ Permite a criação de produtos personalizados com qualidade profissional e baixo custo operacional.

6️⃣ A máquina precisa de manutenção especial?

🔧 Embora seja de baixa manutenção, alguns cuidados garantem maior durabilidade:

✔ Limpeza da lente e dos espelhos para manter a qualidade da gravação.

✔ Verificação de resíduos na mesa de trabalho para evitar obstruções.

✔ Manutenção do sistema de resfriamento (se aplicável) para evitar superaquecimento.

Com a manutenção adequada, a máquina funciona de forma eficiente e com mínimo tempo de inatividade.

7️⃣ Qual a velocidade de gravação e corte da máquina?

⚡ Depende do material e da complexidade do design. No entanto, a máquina é altamente eficiente, garantindo gravações e cortes rápidos sem comprometer a qualidade. Projetos menores e designs simples podem ser finalizados em poucos minutos.

8️⃣ Qual software é compatível com a Máquina de Gravação e Corte a Laser CO₂ para Hobby?

🖥️ A máquina acompanha o software LaserWorks e também é compatível com:

✔ CorelDRAW

✔ AutoCAD

✔ Adobe Illustrator

Isso permite criar designs profissionais e importá-los diretamente para a máquina para gravação ou corte.

9️⃣ Qual a garantia da máquina?

🛡️ A Máquina de Gravação e Corte a Laser CO₂ para Hobby possui garantia limitada de 1 ano, cobrindo defeitos de fabricação.

🚫 Itens não incluídos na garantia:

❌ Custos de envio

❌ Peças consumíveis (como o tubo laser)

Seguindo as diretrizes de manutenção, sua máquina terá uma vida útil longa e eficiente.

🔟 Como posso começar a usar a Máquina de Gravação e Corte a Laser CO₂ para Hobby?

🎯 Passo a passo para iniciar:

✅ Desembale a máquina com cuidado.

✅ Instale o software no seu computador.

✅ Siga o guia de configuração incluído.

✅ Teste os primeiros cortes com os tutoriais disponíveis.

📢 Dúvidas? Nossa equipe de suporte está pronta para ajudar você!

🚀 Pronto para levar seus projetos criativos para o próximo nível? Comece agora!

Mais vídeos de gravação e corte a laser

Solicite um orçamento para uma máquina de gravação e corte a laser CO₂

A SISMAR LASER oferece Máquinas de Gravação e Corte a Laser CO₂ e outras soluções para diversas aplicações industriais. Nossos equipamentos podem ser um upgrade para o seu sistema atual ou a escolha ideal para a sua primeira máquina a laser.

📌 Solicite um orçamento para uma máquina de gravação e corte a laser CO₂ de alta qualidade que supera suas expectativas.

📢 Agende uma demonstração e veja de perto como a tecnologia de gravação e corte a laser CO₂ pode transformar seus processos! 🚀

🔹 Bem-vindo à SISMAR LASER! 🔹

Estamos à disposição para responder a todas as suas perguntas sobre nossas máquinas de marcação e corte a laser Fiber e CO₂. 🚀

Fale conosco e descubra a solução perfeita para o seu negócio! 💡✨