Macchina per saldatura laser di gioielli a pedana

March 19, 2025 /0 Comments/in Language /by linda

Macchina per saldatura laser di gioielli da 200W

Macchina per saldatura laser di gioielli a pedana

Macchina per saldatura laser di gioielli da 200W: Precisione e Potenza 💎

La Macchina per saldatura laser di gioielli da 200W offre alta precisione e potenza eccezionale per la saldatura di oro, platino, argento e titanio.

🔹 Caratteristiche principali:

✅ Laser da 200W per saldature profonde e rapide.

✅ Massima precisione per riparazioni dettagliate e incastonatura di pietre.

✅ Versatile, ideale per gioielleria, elettronica e dispositivi medici.

✅ Design ergonomico per un utilizzo confortevole.

✅ Sistema di raffreddamento avanzato per prestazioni costanti.

La scelta perfetta per professionisti che cercano risultati affidabili e precisi! ✨

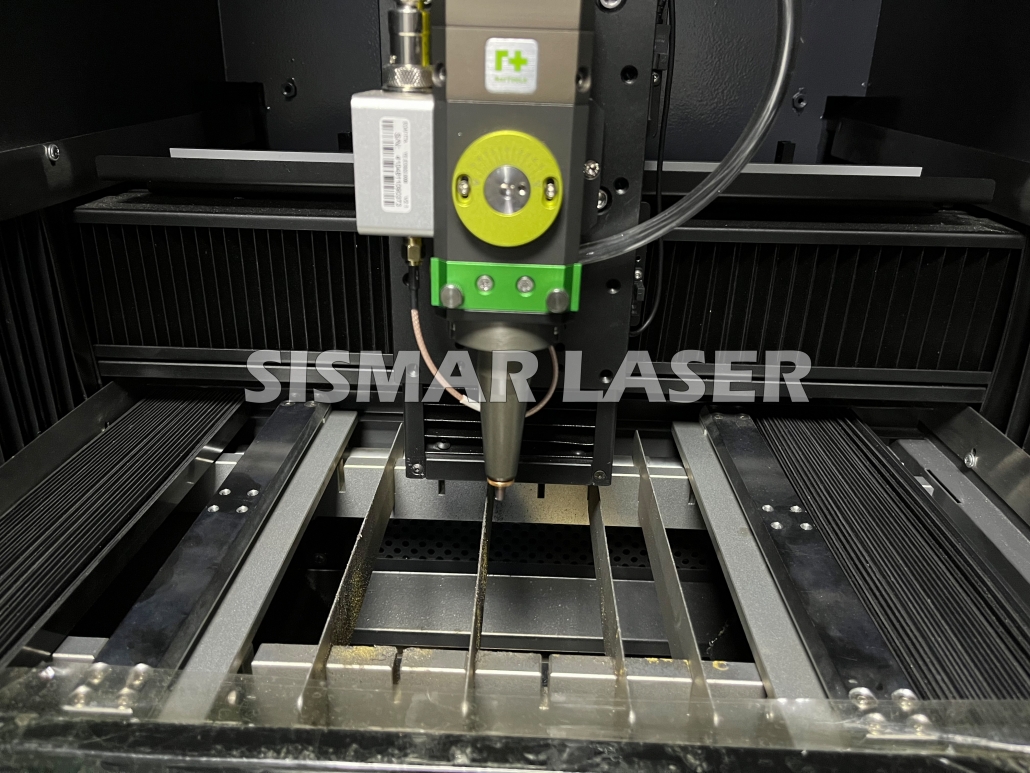

Macchina per saldatura laser di gioielli a pedana Foto

Trasforma le tue riparazioni di gioielli con la Macchina per Saldatura Laser a Pedana ✨

Stanco di metodi di saldatura tradizionali che rischiano di danneggiare i tuoi gioielli più delicati? La Macchina per Saldatura Laser a Pedana è qui per rivoluzionare il tuo modo di lavorare e creare! 🔥

💎 Perché questa macchina è un vero punto di svolta:

✅ Precisione & Perfezione: Ottieni saldature pulite, forti e precise ogni volta, indipendentemente dalla complessità del design. Niente più saldature irregolari o bordi fusi, solo risultati impeccabili!

✅ Controllo Totale: Le impostazioni di potenza regolabili consentono una saldatura ultra-precisa anche sui gioielli più delicati, garantendoti il massimo controllo.

✅ Design a Pedana per Maggiore Flessibilità: Il design a pedana permette un utilizzo più comodo e versatile, mantenendo il pezzo da saldare all’altezza ideale per l’operatore. Lavora senza sforzo, indipendentemente dal progetto!

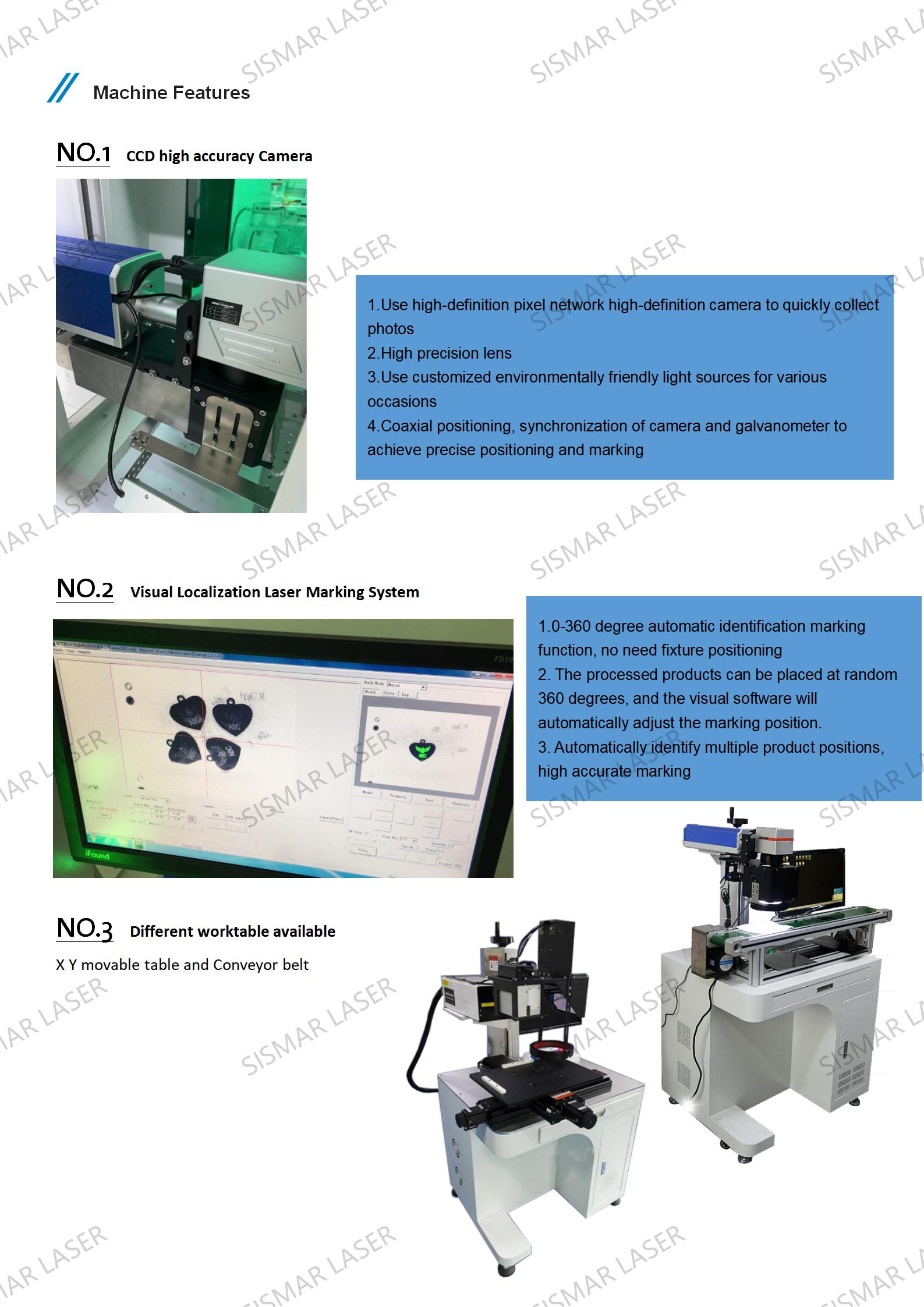

✅ Microscopio ad Alta Precisione: Grazie al microscopio integrato, hai una visione chiara e ingrandita dell’area di saldatura, per un controllo perfetto di ogni dettaglio.

✅ Sistema CCD (Opzionale): Per lavorare su pezzi più grandi, il sistema CCD opzionale offre una visione completa del processo, assicurando risultati di alta qualità ogni volta.

🚀 I principali vantaggi:

🔥 Velocità & Efficienza: Saldatura rapida ed efficace, con calore minimo, preservando l’integrità dei tuoi pezzi.

💪 Saldature Resistenti: Perfetta per riparazioni e per fissare piccoli componenti senza compromettere la resistenza.

🛠️ Compatta & Professionale: Il design a pedana salva spazio e si integra perfettamente nel tuo laboratorio.

🔹 Pronto a portare la tua arte orafa al livello successivo?

La Macchina per Saldatura Laser a Pedana è lo strumento ideale per chi cerca precisione, velocità e risultati impeccabili. Non aspettare oltre—acquistala oggi stesso e inizia a creare i capolavori che hai sempre sognato! 🌟

📊 Caratteristiche Tecniche:

| Categoria | Dettagli |

|---|---|

| Piattaforma di Sistema | Pedana |

| Certificazione di Sicurezza | Classe 1 (Camera di Saldatura) |

| Classe del Sistema Laser | Classe 4 |

| Lunghezza d’Onda | 1.064nm |

| Alimentazione | 220V±10%, 50Hz/60Hz |

| Sorgente Laser | ND:YAG |

| Larghezza dell’Impulso | 0.1 – 10ms |

| Potenza Media | 200W |

| Durata Impulso | 0.1 – 50ms |

| Frequenza Impulso | ≤50Hz |

| Saldatura a Raffica / Velocità | Ottimizzata per valori energetici |

| Diametro del Raggio | 0.05mm – 2.00mm |

| Sistema di Raffreddamento | Acqua-Aria Interno |

| Circuito di Alimentazione | 220V±10%, 50Hz/60Hz |

| Microscopio Binoculare | 15x (opzionale: 25x, 40x) |

| Illuminazione Camera | LED Luce Naturale |

| Sistema di Osservazione | Microscopio |

| Memorizzazione Parametri | 10 gruppi |

| Allarme di Protezione | Sì |

| Opzioni Lingua Display | Inglese |

| Alimentazione Gas Protettivo | Connessione rapida (argon) |

| Sistema di Raffreddamento | Chiller ad acqua |

| Ambiente di Funzionamento | Temp 5°C – 30°C, Umidità 5% – 75% |

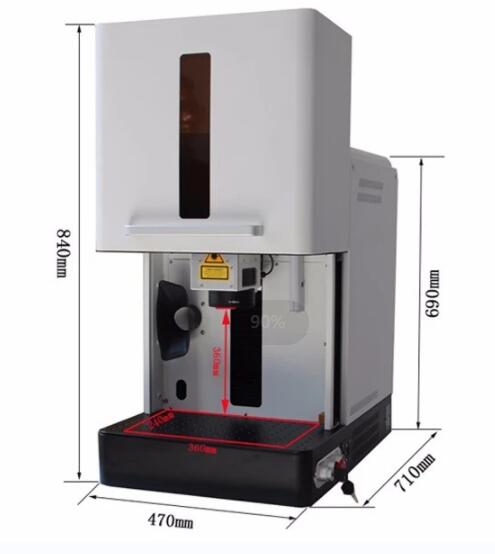

| Dimensioni Macchina | 1160x640x1410mm |

| Dimensioni Chiller | 740x600x1090mm |

| Peso (Senza Imballo) | 200kg |

💎 Investi nella massima qualità e precisione—scegli la Macchina per Saldatura Laser a Pedana e trasforma il tuo lavoro ora! 🚀

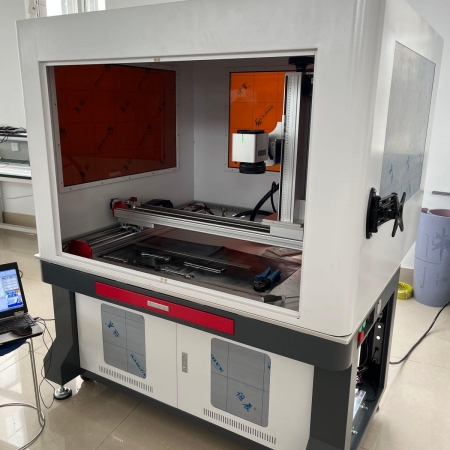

Macchina per Saldatura Laser a Pedana: Precisione e Prestazioni Senza Rivali ✨

Progettata su misura per i professionisti della gioielleria, la Macchina per Saldatura Laser a Pedana combina un design ergonomico, funzionalità avanzate e una precisione ineguagliabile per garantire risultati perfetti ogni volta.

💎 Caratteristiche Principali della Macchina per Saldatura Laser a Pedana:

✅ Design Ergonomico per il Massimo Comfort:

Pensata per soddisfare le esigenze dell’industria orafa, questa macchina offre precisione estrema, estetica raffinata, prestazioni stabili e la capacità di operare in modo continuo e senza interruzioni.

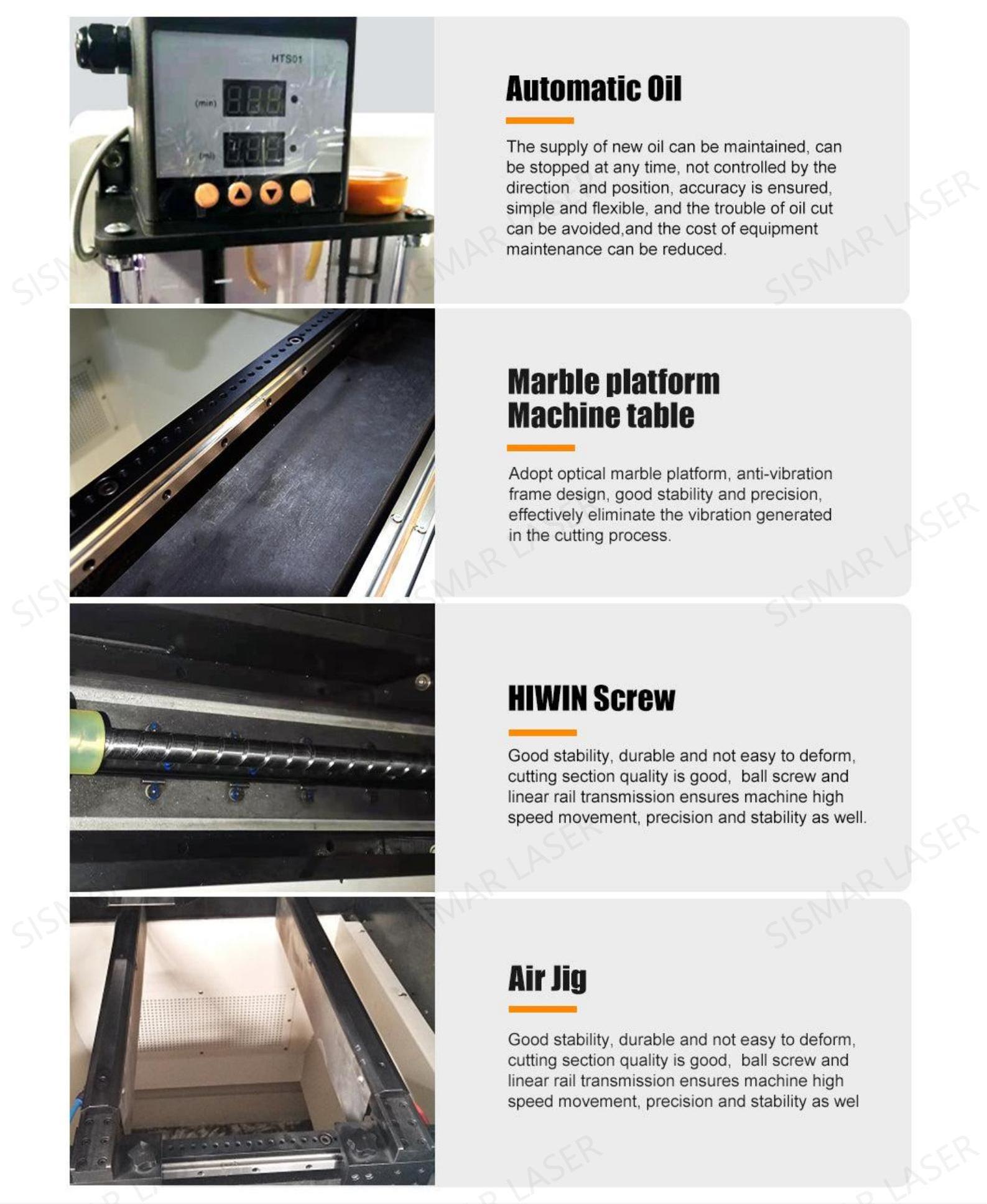

✅ Ampio Spazio Interno per Strumenti e Accessori:

Grazie a uno spazio interno generoso, puoi organizzare facilmente i tuoi strumenti e accessori, mantenendo un’area di lavoro ordinata e altamente produttiva.

✅ Funzionamento Fluido e Preciso:

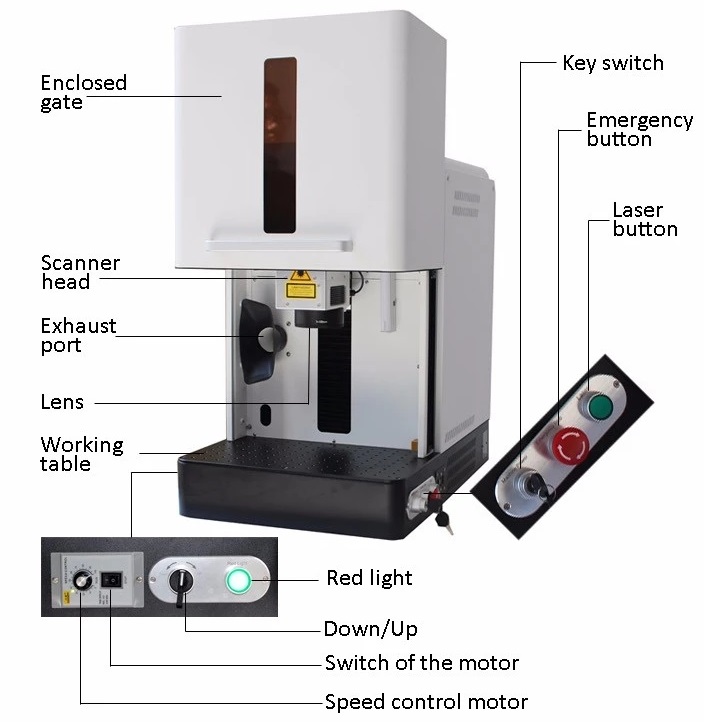

Dotata di meccanismo di messa a fuoco elettrico, display digitale con scala di lettura e un interruttore di regolazione dei parametri laser, questa macchina garantisce prestazioni fluide e costanti.

✅ Manutenzione Semplice:

Il filtro antipolvere sostituibile facilita la pulizia dell’area di lavoro, mentre il sistema di riciclo gestisce in modo efficiente gli scarti di saldatura, mantenendo la postazione sempre pulita.

✅ Massima Visibilità per Saldature Precise:

Grazie a una lampada LED ad anello per un’illuminazione brillante e a un microscopio tedesco di alta qualità, avrai una visione cristallina della zona di saldatura, per individuare anche i dettagli più minuti.

✅ Punto Luce Ultra Preciso per Saldature Perfette:

Il raggio laser estremamente preciso garantisce saldature di altissimo livello, rendendo questa macchina ideale per i lavori di gioielleria più delicati.

🚀 Perché scegliere questa macchina?

✨ Comfort senza sforzo grazie al design ergonomico.

🔍 Osservazione cristallina per risultati impeccabili.

⚡ Tecnologia avanzata per saldature affidabili e perfette.

🔥 Porta la tua arte orafa a un livello superiore con la Macchina per Saldatura Laser a Pedana—lo strumento definitivo per precisione, efficienza e prestazioni durature. Acquistala oggi stesso e trasforma il tuo lavoro! 🌟

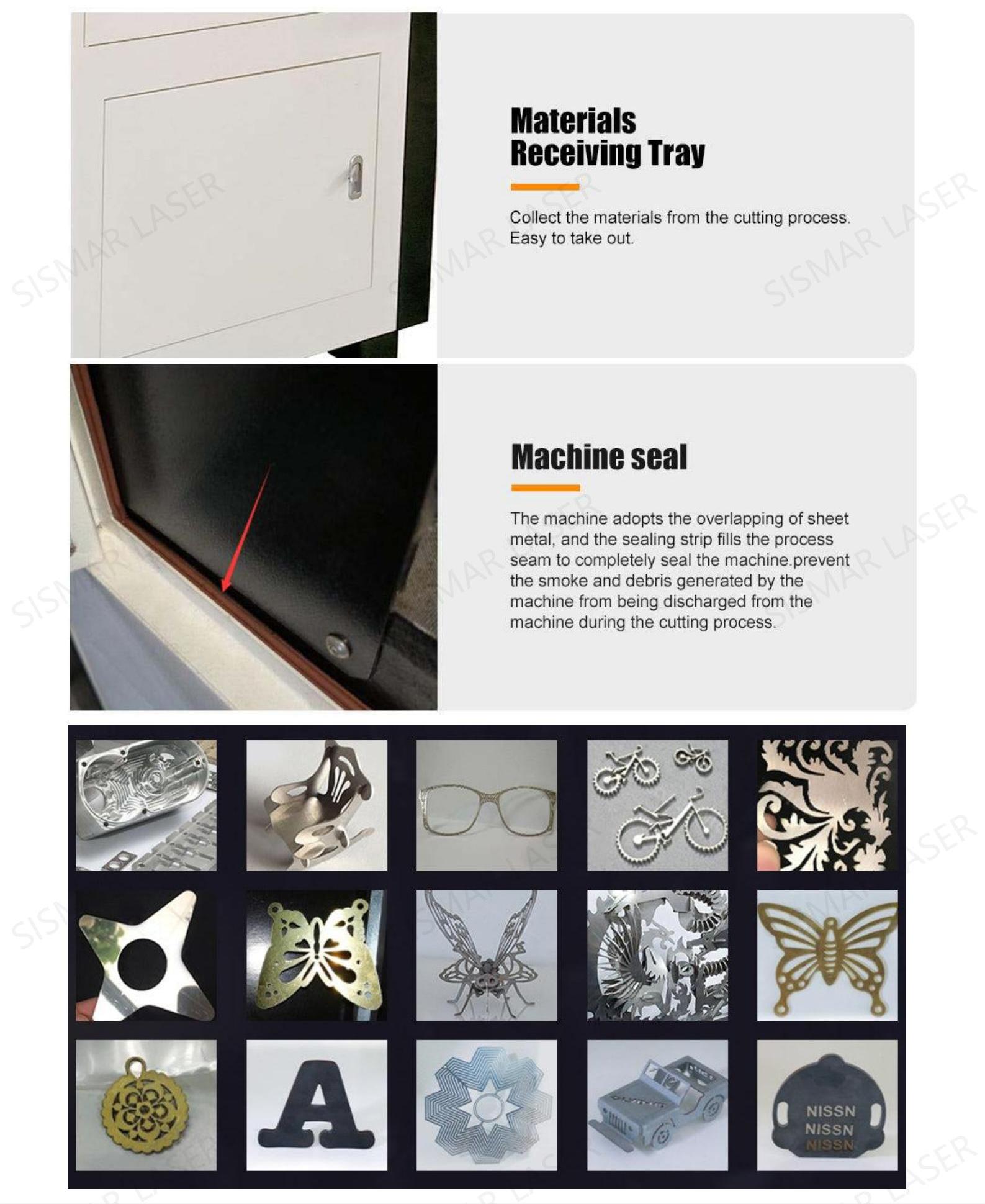

Applicazioni della Macchina per Saldatura Laser a Pedana ✨

La Macchina per Saldatura Laser a Pedana è uno strumento essenziale per numerosi settori, offrendo saldature di alta precisione su un’ampia gamma di materiali. Grazie alla sua versatilità, è la soluzione ideale nei seguenti ambiti:

💎 Applicazioni Principali:

✈️ Aviazione & Aerospaziale: Perfetta per la saldatura di componenti delicati in settori ad alta precisione.

💍 Gioielleria: Ideale per la lavorazione di argento, platino, titanio e acciaio inossidabile, incluse saldature puntuali, riparazione di fori e incastonatura di pietre preziose e griffes.

🏌️ Attrezzature Sportive: Precisione assoluta nella saldatura di teste di mazze da golf e altri articoli sportivi.

🏥 Dispositivi Medici: Utilizzata per la saldatura di strumenti medicali e protesi in alluminio, garantendo resistenza e accuratezza.

📟 Elettronica & Strumentazione: Essenziale per la saldatura di componenti elettronici e strumenti di precisione.

🚗 Industria Automobilistica: Un alleato prezioso nella saldatura di parti meccaniche con estrema precisione.

Grazie alle sue funzionalità avanzate, questa macchina affronta anche le lavorazioni più complesse, rendendosi indispensabile in questi settori. 🌟

FAQ – Macchina per Saldatura Laser a Pedana per Gioielleria

1️⃣ Cos’è una Macchina per Saldatura Laser a Pedana per Gioielleria?

Una Macchina per Saldatura Laser a Pedana è un dispositivo specializzato per la saldatura di precisione di parti metalliche, utilizzato principalmente nella produzione e riparazione di gioielli. Grazie a un raggio laser focalizzato, fonde e unisce i metalli senza danneggiare i materiali circostanti, garantendo una saldatura pulita, precisa ed efficiente.

2️⃣ Come funziona una Macchina per Saldatura Laser a Pedana?

La macchina emette un raggio laser altamente focalizzato che colpisce l’area di giunzione dei metalli da saldare. Il calore generato dal laser fonde i metalli, permettendo loro di legarsi. Questo processo è perfetto per lavori delicati come riparare gioielli, ridimensionare anelli o saldare piccoli componenti senza alterare il materiale circostante.

3️⃣ Quali materiali possono essere saldati con questa macchina?

Questa macchina è ideale per la saldatura di metalli preziosi come oro, argento, platino e palladio, oltre a leghe utilizzate in oreficeria. Inoltre, può essere utilizzata anche per alcuni metalli di base come rame e acciaio inossidabile, a seconda delle specifiche della macchina.

4️⃣ Quali sono i principali vantaggi di una Macchina per Saldatura Laser a Pedana?

🔹 Precisione Assoluta: Il laser fornisce un’energia altamente focalizzata, perfetta per saldature delicate su gioielli intricati.

🔥 Minima Zona Termicamente Alterata (HAZ): Il controllo preciso del laser riduce al minimo la deformazione e i danni da calore.

💎 Nessun Materiale d’Apporto Necessario: In molti casi, la saldatura può essere eseguita senza aggiunta di materiale, preservando l’estetica del gioiello.

⚡ Maggiore Efficienza: Tempi di saldatura rapidi e minori costi di manodopera, migliorando la produttività.

✨ Finitura Perfetta: Il raggio laser crea una saldatura liscia e pulita, senza necessità di ulteriori rifiniture.

5️⃣ La Macchina per Saldatura Laser a Pedana è facile da usare?

Sì! Questa macchina è progettata per essere intuitiva e user-friendly. Molti modelli dispongono di schermi touchscreen, impostazioni regolabili per diversi materiali e funzioni di controllo preciso della profondità e della potenza della saldatura. Anche se la formazione è minima, per ottenere i migliori risultati potrebbe essere necessario fare pratica con le diverse impostazioni.

6️⃣ Quali precauzioni di sicurezza bisogna adottare?

🕶️ Protezione per gli occhi: Indossare sempre occhiali di sicurezza per laser per proteggere la vista dalla luce intensa.

💨 Ventilazione adeguata: Assicurarsi di lavorare in un’area ben ventilata per evitare di inalare fumi tossici, specialmente quando si saldano leghe che rilasciano vapori nocivi.

🧤 Abbigliamento protettivo: Utilizzare guanti e indumenti adeguati per prevenire ustioni o contatti accidentali con parti calde.

7️⃣ Posso riparare i miei gioielli con questa macchina?

Assolutamente sì! Le Macchine per Saldatura Laser a Pedana sono ampiamente utilizzate per la riparazione di gioielli, tra cui:

🔗 Riparazione di chiusure rotte

💍 Ridimensionamento di anelli

💎 Reincastonatura di pietre preziose

🔧 Riattacco di componenti minuti

Grazie alla loro precisione, consentono riparazioni efficaci senza dover rifare l’intero pezzo.

8️⃣ Qual è la differenza tra una Macchina per Saldatura Laser a Pedana e una saldatrice laser standard?

🔹 La versione a pedana è più compatta ed ergonomica, ideale per lavori delicati su gioielli e piccoli pezzi.

🔹 Le saldatrici laser standard tendono ad essere più grandi e progettate per applicazioni industriali o automobilistiche.

Se lavori nella gioielleria, la Macchina per Saldatura Laser a Pedana è la scelta perfetta per ottenere saldature di precisione su piccoli componenti.

9️⃣ Quanto costa una Macchina per Saldatura Laser a Pedana?

Il prezzo varia in base a marca, caratteristiche e specifiche tecniche, ma generalmente oscilla tra $5.000 e $20.000 USD.

💡 Investire in questa macchina significa ottenere un rapido ritorno economico, grazie alla migliorata efficienza e qualità della saldatura.

🔟 Quale manutenzione è necessaria per la Macchina per Saldatura Laser a Pedana?

Per mantenere la macchina sempre al massimo delle prestazioni, è importante seguire una manutenzione regolare:

✔ Pulizia delle lenti e degli specchi laser per garantire prestazioni ottimali.

✔ Controllo del sistema di raffreddamento per evitare surriscaldamenti.

✔ Calibrazione periodica per mantenere l’accuratezza della saldatura.

✔ Sostituzione di parti usurate come tubi laser o fusibili, se necessario.

🔥 Pronto a portare la tua arte orafa al livello successivo? La Macchina per Saldatura Laser a Pedana è il tuo alleato perfetto per precisione, efficienza e risultati impeccabili! 🌟

Video di saldatura laser per gioielli

Richiedi un preventivo per una macchina per saldatura laser per gioielli

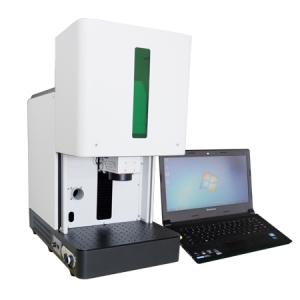

SISMAR LASER offre macchine per saldatura laser e altre soluzioni per molte applicazioni industriali.

Le nostre soluzioni possono rappresentare un upgrade ideale per il tuo attuale sistema di saldatura laser o essere la scelta perfetta per la tua prima macchina laser.

💎 Richiedi un preventivo per una macchina per saldatura laser per gioielli di alta qualità che superi le tue aspettative.

🔍 Vuoi vederla in azione? Prenota una demo e scopri come funziona la saldatura laser per gioielli!

Benvenuto in SISMAR LASER! 🎉

Siamo lieti di rispondere a tutte le tue domande sulle nostre macchine laser a fibra per marcatura e taglio. 💡✨

📩 Contattaci ora per maggiori informazioni! 🚀