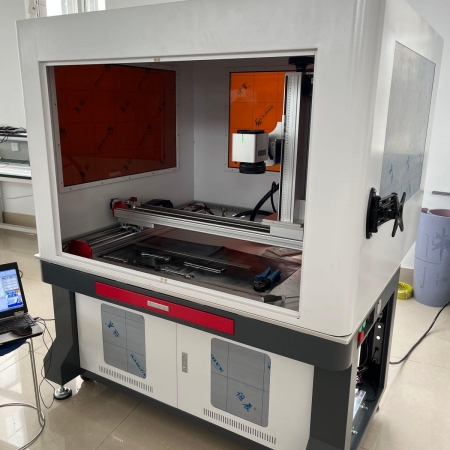

Opis maszyny

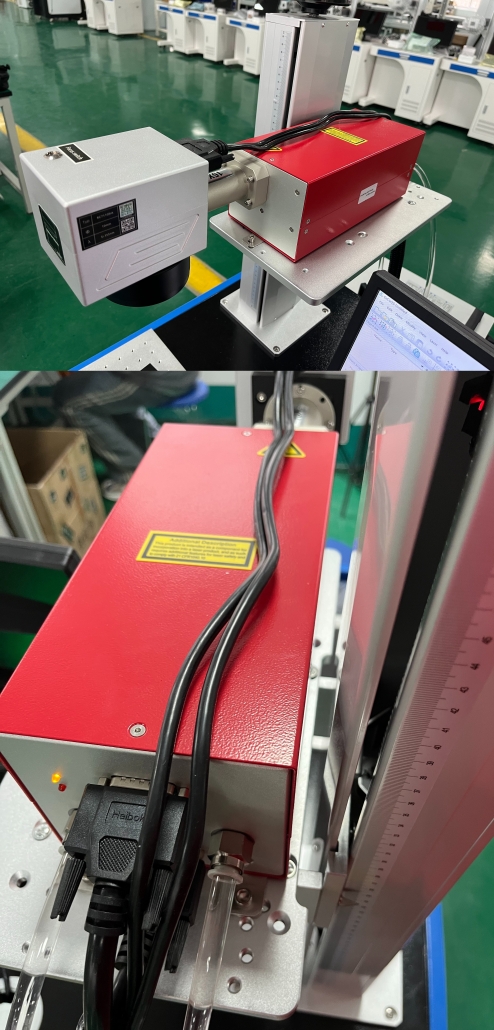

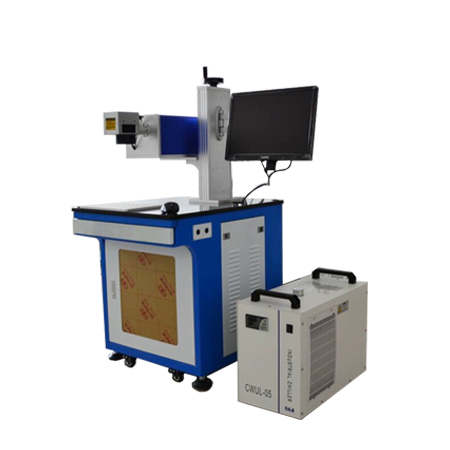

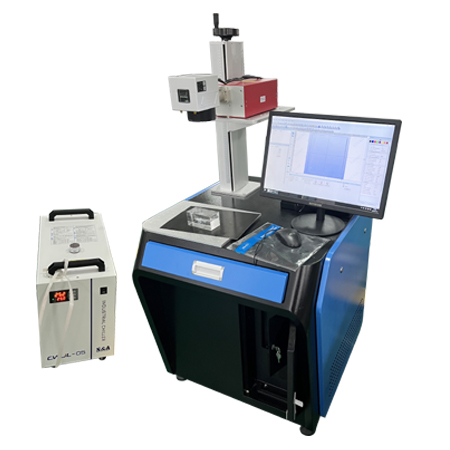

Maszyna do znakowania UV – Idealne narzędzie do precyzyjnego i wysokiej jakości grawerowania

Masz dość zamazanych, niejednolitych grawerunków na swoich produktach? Maszyna do znakowania UV zmienia zasady gry. Dzięki długości fali 355nm, ta maszyna zapewnia wyjątkowo cienkie i precyzyjne oznaczenia na plastiku, metalu, szkle i innych materiałach wrażliwych na ciepło. Niezależnie od tego, czy zajmujesz się elektroniką, urządzeniami medycznymi, jubilerstwem czy pakowaniem kosmetyków, maszyna do znakowania UV to narzędzie, które podniesie jakość Twojego produktu.

Dlaczego ta maszyna to przełom: ✨ Bezdyskusyjna precyzja: Uzyskaj ostre, szczegółowe grawerunki, które są dosłownie ułamkiem mikrona. Koniec z rozmytymi lub nieregularnymi oznaczeniami — tylko czysta precyzja. 🔥 Brak uszkodzeń cieplnych: W przeciwieństwie do tradycyjnych laserów, laser UV nie uszkadza ani nie odkształca delikatnych materiałów. Idealny do plastiku i materiałów pokrytych powłoką, które wymagają precyzji bez wpływu ciepła. ⚡ Ekstremalna szybkość: Czas to pieniądz, prawda? Ta szybka maszyna laserowa nie tylko dostarcza doskonałe rezultaty, ale robi to w ekspresowym tempie, więc możesz zrobić więcej w krótszym czasie. 🔧 Całkowita wszechstronność: Niezależnie od tego, czy znakujesz logo, numery seryjne, czy niestandardowe wzory, maszyna do znakowania UV poradzi sobie z tym wszystkim – w elektronice, urządzeniach medycznych, jubilerstwie i wielu innych branżach.

Kluczowe korzyści, których nie możesz zignorować: ✅ Czyste, wyraźne rezultaty: Maszyna do znakowania UV dostarcza precyzyjne grawerunki, które wyróżniają się – idealne, aby dodać Twojemu produktowi profesjonalizmu. 🌱 Ekologiczna i wydajna: Ta energooszczędna maszyna nie tylko oszczędza czas, ale także zmniejsza odpady, co czyni ją bardziej zrównoważonym wyborem dla Twojego biznesu. 🛡️ Trwałość na lata: Grawerunki wykonane za pomocą lasera UV są trwałe, odporne na ścieranie i niezwykle trwałe, co sprawia, że są idealne do produktów wysokiej jakości, które wymagają długotrwałej identyfikacji.

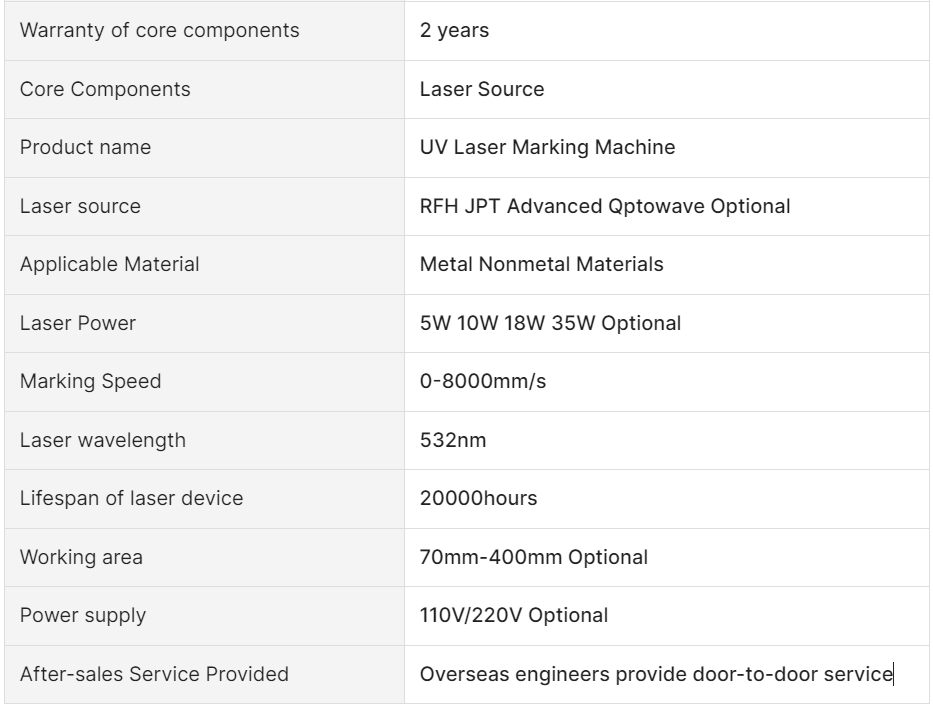

Maszyna do znakowania UV – Specyfikacja

| Parametr |

Opis |

| Typ lasera |

Laser UV (355nm) |

| Opcje mocy lasera |

3W, 5W, 10W, 20W |

| Pole znakowania |

110mm x 110mm, 150mm x 150mm, 200mm x 200mm |

| Szybkość znakowania |

Do 8000mm/s |

| Głębokość znakowania |

0.01mm – 1mm (w zależności od materiału) |

| Jakość wiązki |

M2 < 1.5 |

| Metoda chłodzenia |

Chłodzenie powietrzem lub wodą |

| Minimalna szerokość linii |

0.01mm |

| Dokładność powtarzalności |

≤ 0.002mm |

| Żywotność robocza |

≥ 100,000 godzin |

| Zasilanie |

AC 110V/220V ±10%, 50/60Hz |

| System operacyjny |

Oprogramowanie oparte na systemie Windows (EZCAD itp.) |

| Kompatybilność materiału |

Plastik, metal, szkło, ceramika, powierzchnie pokryte powłoką |

| Wymiary maszyny |

800mm x 750mm x 500mm |

| Waga |

50kg – 100kg (w zależności od konfiguracji) |

Te parametry maszyny do znakowania UV zapewniają wysoką precyzję grawerowania i znakowania dla różnych zastosowań, od elektroniki po jubilerstwo. Wszechstronność i szybkość maszyny sprawiają, że jest to idealny wybór dla branż, które wymagają wysokiej jakości i wydajnych rozwiązań do znakowania laserowego.

Gotowy, by wnieść grawerowanie na wyższy poziom? Maszyna do znakowania UV zwiększy Twoją produktywność, poprawi jakość produktów i da Ci przewagę konkurencyjną. Nie zadowalaj się niczym mniej niż perfekcją – uzyskaj precyzję i szybkość, na które zasługujesz, z maszyną do znakowania UV.

Zaleta

UV Laser Marking Machine – Największa Przewaga Dla Twojego Biznesu

Szukasz maszyny do znakowania laserowego, która zapewni precyzję, szybkość i niezrównaną jakość? UV Laser Marking Machine to idealne rozwiązanie, oferujące korzyści, których inne systemy laserowe po prostu nie mogą dorównać.

1. Wyjątkowa Precyzja

UV Laser Marking Machine oferuje precyzję sub-mikronową, zapewniając wyraźne, czyste i niesamowicie szczegółowe grawerunki. Niezależnie od tego, czy znakujesz logotypy, numery seryjne czy skomplikowane wzory, za każdym razem otrzymasz doskonałe rezultaty. Dzięki zdolności do wycinania najdrobniejszych detali, ta maszyna jest idealna do produktów premium, gdzie precyzja jest kluczowa.

2. Brak Uszkodzeń Termicznych

Jednym z największych problemów tradycyjnych systemów laserowych jest zniekształcenie cieplne, które powodują wrażliwe materiały. Nie w przypadku UV Laser Marking Machine! Ta maszyna działa z minimalną ilością ciepła, co czyni ją idealną do delikatnych powierzchni, takich jak tworzywa sztuczne, cienkie metale i materiały pokryte powłokami. Możesz uzyskać wysokiej jakości grawerunki, nie martwiąc się o uszkodzenia czy wypaczenie materiału.

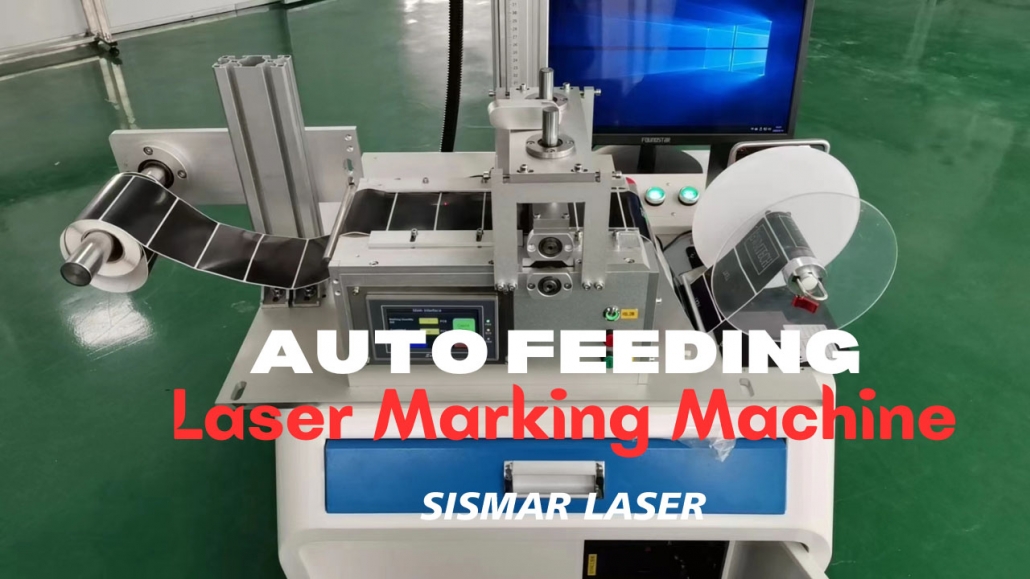

3. Szybsza Produkcja, Większa Wydajność

W dzisiejszym, szybkim rynku, szybkość ma kluczowe znaczenie. UV Laser Marking Machine nie tylko oznacza szybko, ale robi to bez utraty jakości. Dzięki swoim możliwościom wysokiej prędkości, będziesz w stanie oznaczyć więcej produktów w krótszym czasie, maksymalizując swoją wydajność i poprawiając wyniki finansowe.

4. Ekologiczne i Kosztowo Efektywne

Technologia UV Laser jest energooszczędna i przyjazna dla środowiska, produkując minimalną ilość odpadów, przy maksymalnej wydajności. Oszczędzisz na kosztach operacyjnych i przyczynisz się do bardziej zrównoważonej przyszłości – wszystko to bez kompromisów w zakresie wydajności. To rozwiązanie typu “win-win”.

5. Długoterminowa Trwałość

Inwestując w UV Laser Marking Machine, otrzymujesz narzędzie, które zostało zaprojektowane z myślą o długowieczności. Stworzona do niskiej konserwacji i wysokiej niezawodności, ta maszyna będzie dostarczać najwyższej jakości wyniki przez lata. Jej trwała konstrukcja oznacza mniej napraw i przerw w produkcji, co oszczędza Twój czas i pieniądze w dłuższej perspektywie.

6. Wszechstronne Zastosowania

Od elektroniki, przez urządzenia medyczne, biżuterię, aż po kosmetyki, UV Laser Marking Machine radzi sobie z szeroką gamą materiałów i branż. Niezależnie od tego, czy musisz oznaczyć numery seryjne, kody kreskowe, czy logotypy, ta maszyna dostosowuje się do Twoich potrzeb, oferując Ci absolutną elastyczność.

Dlaczego warto wybrać UV Laser Marking Machine?

- Precyzja, która zapewnia bezbłędne grawerunki

- Minimalne ciepło, aby chronić Twoje delikatne materiały

- Wysoka szybkość pracy, która zwiększa wydajność

- Ekologiczne i kosztowo efektywne

- Zbudowana do trwałości, z minimalną konserwacją

UV Laser Marking Machine to idealne narzędzie dla firm, które wymagają dokładności, szybkości i wszechstronności. Przestań zadowalać się przeciętnością i zacznij dostarczać najwyższej jakości grawerunki na każdym produkcie. Twoi klienci zauważą różnicę – a także Twoje wyniki finansowe.

Zastosowanie

Maszyna do znakowania UV – Precyzja w znakowaniu szkła, plastiku i PCB

Jeśli szukasz najwyższej precyzji i niezrównanej jakości do delikatnych materiałów, Maszyna do znakowania UV to idealne rozwiązanie. Dzięki swojej ultrakrótkiej długości fali (355 nm), ta maszyna zapewnia niezawodne i bezkontaktowe znakowanie, gwarantując wysoką jakość wyników bez uszkadzania produktów. Przyjrzyjmy się głównym zastosowaniom, w których laser UV naprawdę błyszczy:

1. Znakowanie Szkła: Czyste, Ostro Wyryte i Trwałe Grawerunki

W przypadku znakowania szkła, niezależnie od tego, czy pracujesz nad luksusowymi przedmiotami, butelkami czy wykwintną szklarnią, Maszyna do znakowania UV zapewnia ostre, kontrastowe grawerunki, które nie powodują pęknięć ani zniekształceń termicznych. Niezależnie od tego, czy chodzi o markowanie logo, czy kody QR, laser UV zapewnia precyzyjne i trwałe wzory.

2. Znakowanie Plastiku: Czyste Detale Bez Uszkodzeń Termicznych

Dla branż używających plastiku, takich jak elektronika użytkowa, części motoryzacyjne czy urządzenia medyczne, technologia lasera UV wyróżnia się na tle tradycyjnych systemów. Zamiast powodować topnienie, odkształcenia czy blaknięcie koloru, laser UV skutecznie znakowa plastiki. Niezależnie od tego, czy pracujesz z ABS, PVC, czy PC, uzyskasz czyste, trwałe oznaczenia, które będą ostre przez długi czas.

3. Znakowanie PCB: Ultra-Precyzyjne, Czyste i Niezawodne

Jeśli chodzi o znakowanie płyt drukowanych (PCB), lasery UV są bezkonkurencyjne. Dzięki wysokiej precyzji i minimalnemu wytwarzaniu ciepła, możesz znakować numery seryjne, kody kreskowe i logo na PCB bez obawy o uszkodzenie wrażliwych komponentów. Laser UV tworzy wyraźne i trwałe oznaczenia, które zachowują integralność elektroniki.

4. Kosmetyki & Opakowania: Delikatne, Bezpieczne Znakowanie

Dla opakowań kosmetyków oraz małych szklanych czy plastikowych pojemników, laser UV to idealne rozwiązanie do skomplikowanych wzorów i markowania. Bez zniekształceń termicznych i bezkontaktowego znakowania, uzyskujesz szczegółowe i czyste grawerunki, które podnoszą atrakcyjność produktu bez uszkadzania materiału.

Dlaczego warto wybrać Maszynę do Znakowania UV?

Maszyna do Znakowania UV to doskonałe narzędzie dla branż, które wymagają precyzyjnych, bezuszkodzeniowych znaków i trwałych grawerunków na materiałach takich jak szkło, plastik i PCB. Jeśli działasz w branżach takich jak elektronika, kosmetyki czy biżuteria, laser UV jest najlepszym wyborem dla wysokiej jakości, wyraźnych i trwałych oznaczeń.

Dzięki zdolności pracy na delikatnych powierzchniach przy zachowaniu wyjątkowej precyzji, laser UV pomoże Twojej firmie produkować produkty najwyższej jakości, które wyróżnią się na rynku.

Porównanie lasera światłowodowego i lasera CO₂

Maszyna do Znakowania UV vs. Maszyna do Znakowania Laserowego Włókna vs. Maszyna do Znakowania CO2: Jaka Jest Różnica?

Jeśli zależy Ci na precyzyjnym, czystym znakowaniu, grawerowaniu lub cięciu, wybór odpowiedniej maszyny do znakowania laserowego ma kluczowe znaczenie. Ale przy tak wielu opcjach, wybór może być trudny. Rozbijmy kluczowe różnice między maszyną do znakowania UV, włóknem laserowym i CO2, aby pomóc Ci dokonać najlepszego wyboru dla Twojego biznesu.

1. Precyzja i Detale: Kto Wygrywa?

Maszyna do Znakowania UV: Maszyna UV zdecydowanie wygrywa, jeśli chodzi o precyzyjne, drobne prace. Jeśli musisz oznaczać małe elementy, skomplikowane logotypy czy numery seryjne z precyzją submikronową, laser UV to najlepszy wybór. To rewolucyjne rozwiązanie do grawerowania o wysokiej precyzji na plastiku, szkle i powlekanych metalach. Żaden inny laser nie osiągnie takiego poziomu szczegółowości, jak ta maszyna.

Maszyna do Znakowania Włókna Laserowego: Doskonała do metali, zwłaszcza do grawerowania na stali nierdzewnej, aluminium i innych metalach przemysłowych. Jednak nie dorównuje laserowi UV, szczególnie jeśli chodzi o znakowanie delikatnych materiałów plastikowych lub precyzyjne grawerowanie małych, szczegółowych wzorów.

Maszyna do Znakowania CO2: Choć doskonała do znakowania materiałów niemetalowych, takich jak drewno, plastik i skóra, laser CO2 nie sprawdza się w precyzyjnym znakowaniu metali ani delikatnych detali. Jest świetny do większych powierzchni, ale nie radzi sobie z drobnymi grawerunkami.

2. Wytwarzanie Ciepła: Który Laser Zachowuje Chłodną Głowę?

Maszyna do Znakowania UV: Laser UV używa chłodniejszego procesu—działa z minimalną ilością ciepła, co oznacza, że nie uszkodzi materiałów wrażliwych na ciepło. Otrzymujesz drobne oznaczenia, nie martwiąc się o wypaczenie lub stopienie delikatnych materiałów. To sprawia, że jest idealny do znakowania plastiku, powlekanych powierzchni i cienkich metali.

Maszyna do Znakowania Włókna Laserowego: Laser Włókna generuje więcej ciepła, co może być problematyczne w przypadku plastiku lub cienkich metali. Jeśli nie będziesz ostrożny, może to prowadzić do zniekształceń lub uszkodzeń obrabianego przedmiotu.

Maszyna do Znakowania CO2: Podobnie jak laser Włókna, laser CO2 generuje więcej ciepła. Może to stanowić problem przy pracy z materiałami plastikowymi, powodując ślady spalenizny lub uszkodzenie powierzchni cienkich i delikatnych elementów.

3. Wszechstronność Materiałów: Który Laser Obsługuje Więcej?

Maszyna do Znakowania UV: Laser UV jest niezwykle wszechstronny. Znakować można szeroką gamę materiałów, w tym plastik, szkło, metale, ceramikę, a nawet powierzchnie powlekane. Jest idealny dla branż takich jak elektronika, urządzenia medyczne, biżuteria i kosmetyki, gdzie potrzebna jest elastyczność w pracy z różnymi materiałami bez kompromisów w jakości.

Maszyna do Znakowania Włókna Laserowego: Lasery Włókna to idealne rozwiązanie do znakowania metali, w tym stali nierdzewnej, aluminium i mosiądzu. Jednak nie radzą sobie z materiałami takimi jak plastik i szkło—ograniczone są do metali.

Maszyna do Znakowania CO2: Laser CO2 doskonale sprawdza się w przypadku materiałów niemetalowych, takich jak drewno, plastik i skóra. Jednak nie radzi sobie z znakowaniem metali ani powierzchni powlekanych, co sprawia, że jest mniej wszechstronny od lasera UV i włókna laserowego, jeśli chodzi o różnorodność materiałów.

4. Szybkość: Który Laser Jest Szybszy?

Maszyna do Znakowania UV: Szybka i wydajna przy precyzyjnym znakowaniu detali. Może nadążyć za szybkością i jakością, szczególnie przy małych lub delikatnych elementach. Jeśli oznaczasz wiele małych przedmiotów, laser UV zaoszczędzi Ci czas, jednocześnie dostarczając perfekcyjne rezultaty.

Maszyna do Znakowania Włókna Laserowego: Bardzo szybka w znakowaniu metali. Jeśli pracujesz z metalami i musisz oznaczyć dużą ilość przedmiotów, laser Włókna wykona zadanie błyskawicznie.

Maszyna do Znakowania CO2: Szybkość może się różnić w zależności od materiału, ale laser CO2 jest ogólnie wolniejszy niż dwa pozostałe, zwłaszcza przy pracy z drobnymi detalami. Jest najlepszy do oznaczania większych powierzchni na materiałach niemetalowych.

5. Koszt: Który Laser Oferuje Więcej Wartości?

Maszyna do Znakowania UV: Choć lasery UV mają wyższą cenę początkową, ich precyzja, wszechstronność i minimalne wytwarzanie ciepła oznaczają, że otrzymasz długoterminową wartość z tej maszyny. Jeśli Twoja firma potrzebuje wysokiej jakości, precyzyjnego grawerowania na różnych materiałach, laser UV szybko się zwróci.

Maszyna do Znakowania Włókna Laserowego: Niższy koszt początkowy w porównaniu z laserem UV, ale brak możliwości pracy z materiałami niemetalowymi i delikatnymi wzorami. Dobrze sprawdza się przy znakowaniu metali, ale ma ograniczoną wszechstronność.

Maszyna do Znakowania CO2: Przystępna cena, ale jest dobrym wyborem tylko wtedy, gdy pracujesz z materiałami niemetalowymi. Jeśli musisz oznaczać metale lub precyzyjne detale, może nie być najlepszą inwestycją w dłuższej perspektywie.

Który Laser Jest Odpowiedni Dla Ciebie?

- Jeśli potrzebujesz ultra-precyzyjnych, szczegółowych grawerunków na różnych materiałach, takich jak plastik, szkło i metal, wybierz Maszynę do Znakowania UV.

- Jeśli zależy Ci na szybkiej obróbce metali w aplikacjach przemysłowych, laser Włókna będzie najlepszym wyborem.

- Jeśli pracujesz głównie z materiałami niemetalowymi, takimi jak drewno, plastik i skóra, laser CO2 może wciąż spełniać Twoje potrzeby, ale brakuje mu wszechstronności dwóch pozostałych opcji.

Teraz masz jaśniejszy obraz tego, co każda maszyna do znakowania laserowego oferuje—ułatwiając Ci dokonanie najlepszego wyboru dla Twoich potrzeb!

FAQ dotyczące maszyny do znakowania laserem UV

Najczęściej Zadawane Pytania (FAQ) – Maszyna UV Laser Markująca

1️⃣ Czym jest maszyna UV laser markująca?

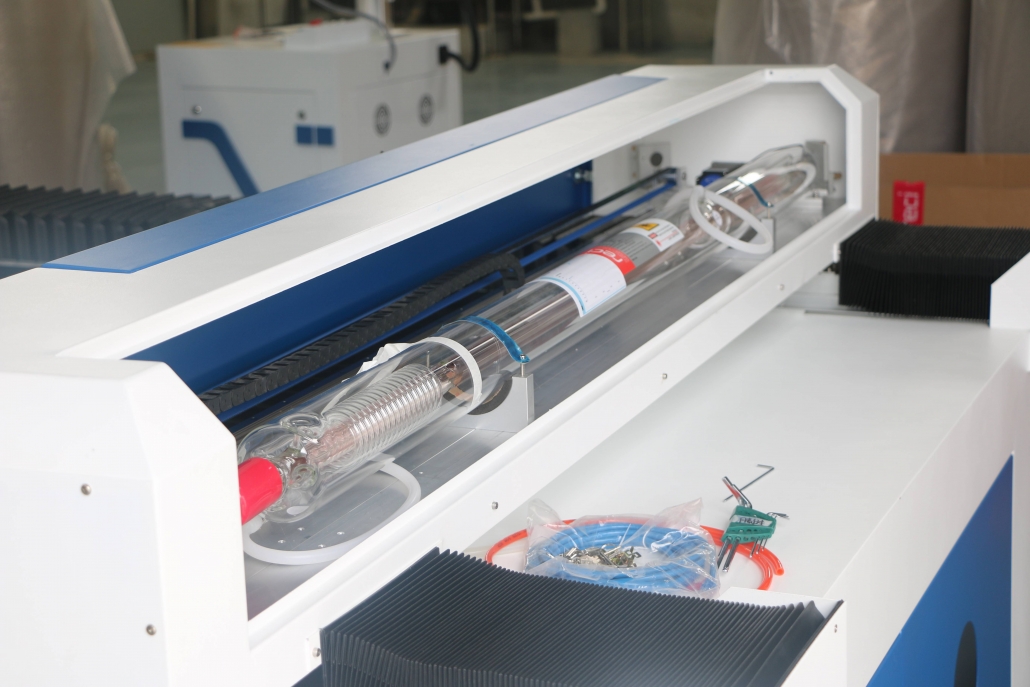

Maszyna UV laser markująca wykorzystuje promieniowanie ultrafioletowe o krótkiej długości fali (355nm), aby tworzyć precyzyjne i kontrastowe oznaczenia na szerokim zakresie materiałów. Ta technologia jest idealna do znakowania delikatnych, precyzyjnych lub wrażliwych na ciepło materiałów, które nie wytrzymają tradycyjnych rodzajów laserów, takich jak lasery CO2 czy światłowodowe. Doskonała do precyzyjnego grawerowania, tekstów, logotypów oraz oznaczeń kodów kreskowych.

2️⃣ Jakie materiały można oznaczać przy pomocy maszyny UV laser markującej?

Maszyna UV laser markująca jest wysoce wszechstronna i może oznaczać różnorodne materiały, w tym:

- Tworzywa sztuczne: ABS, PC, PVC, nylon i inne.

- Szkło: w tym butelki szklane, okna, lustra.

- Ceramika: porcelana, płytki i inne.

- Metale pokryte powłoką: takie jak anodowane aluminium, stal nierdzewna pokryta powłoką.

- Silikon: wykorzystywany w urządzeniach medycznych i elektronice.

- Powierzchnie malowane lub pokryte powłoką: pozostawia czyste i ostre oznaczenia bez uszkadzania materiału bazowego.

Idealna do delikatnych materiałów lub przedmiotów wymagających precyzyjnego oznakowania, takich jak elektronika, urządzenia medyczne, towary luksusowe i inne.

3️⃣ Jak działa maszyna UV laser markująca?

UV laser generuje światło o krótkiej długości fali, które jest wchłaniane przez materiał. Powoduje to minimalne nagrzewanie się materiału, co skutkuje precyzyjnymi, czystymi oznaczeniami. Krótkie fale zapewniają wysoką rozdzielczość i umożliwiają grawerowanie lub oznaczanie precyzyjnych detali z dokładnością do mikronów. UV laser jest szczególnie odpowiedni w przypadkach, gdy tradycyjne lasery mogłyby spowodować zniekształcenie ciepła lub degradację materiału.

4️⃣ Jaka jest prędkość znakowania maszyny UV laser markującej?

Prędkość znakowania maszyny UV laser markującej może różnić się w zależności od modelu i złożoności wzoru oznaczenia. Zwykle prędkość wynosi od 1000mm/s do 8000mm/s, w zależności od zastosowania. Niemniej jednak, ze względu na precyzję wymaganą w znakowaniu UV, prędkość jest równoważona z dokładnością.

5️⃣ Jaka jest moc lasera maszyny UV laser markującej?

Maszyna UV laser markująca zazwyczaj oferuje zakres mocy lasera od 3W do 15W. Opcje o niższej mocy (około 3W-5W) nadają się do delikatnych, szczegółowych prac, natomiast opcje o wyższej mocy (około 8W-15W) mogą być używane do głębszego grawerowania lub cięcia w grubszych lub twardszych materiałach.

6️⃣ Czy maszyna UV laser markująca jest łatwa w obsłudze?

Tak! Maszyna UV laser markująca została zaprojektowana z myślą o łatwości obsługi, z intuicyjnym oprogramowaniem, które pozwala łatwo przesyłać wzory, ustawiać parametry i rozpoczynać proces znakowania. Zwykle posiada interfejs dotykowy oraz automatyczną kalibrację, co zapewnia dokładność. Bez względu na to, czy jesteś początkującym, czy doświadczonym użytkownikiem, maszyna oferuje łatwą konfigurację i obsługę.

7️⃣ Jakie branże korzystają z maszyny UV laser markującej?

Maszyna UV laser markująca jest szeroko stosowana w branżach, które wymagają wysokiej precyzji i czystych oznaczeń na wrażliwych materiałach, takich jak:

- Elektronika: oznaczanie części takich jak PCB, telefony komórkowe i płyty drukowane.

- Urządzenia medyczne: grawerowanie numerów seryjnych, logotypów i kodów kreskowych na narzędziach chirurgicznych, implantach i opakowaniach medycznych.

- Kosmetyki: grawerowanie logotypów lub tekstów na opakowaniach kosmetycznych lub produktach luksusowych.

- Biżuteria: oznaczanie logotypów, numerów seryjnych i spersonalizowanych wzorów na delikatnych elementach biżuterii.

- Opakowania: tworzenie wyraźnych, wysokiej jakości oznaczeń na materiałach opakowaniowych, takich jak butelki i pojemniki.

- Towary luksusowe: grawerowanie numerów seryjnych lub znaków autentyczności na produktach luksusowych.

8️⃣ Jaka jest precyzja maszyny UV laser markującej?

Maszyna UV laser markująca zapewnia nadzwyczajną precyzję z dokładnością grawerowania do 0,001 mm. To sprawia, że jest idealna do zastosowań wymagających drobnych detali, takich jak mały tekst, logotypy i wysokokontrastowe wzory.

9️⃣ Jakie są zalety używania maszyny UV laser markującej?

- Wysoka Precyzja: Osiągnij ostre, szczegółowe oznaczenia z minimalnym zniekształceniem.

- Brak uszkodzeń termicznych: UV laser minimalizuje strefy dotknięte ciepłem, zapewniając, że delikatne materiały pozostaną nietknięte.

- Wszechstronność zastosowań: Może być stosowany na szerokim zakresie materiałów, w tym plastiku, szkła i metali pokrytych powłoką.

- Proces bezkontaktowy: UV laser nie dotyka materiału fizycznie, co pomaga zachować integralność powierzchni.

- Ekologiczne rozwiązanie: Lasery UV nie wymagają materiałów eksploatacyjnych, takich jak tusz czy chemikalia, co sprawia, że są czystsze.

- Długi okres użytkowania: Laser UV charakteryzuje się długowiecznością i wymaga minimalnej konserwacji.

🔟 Czy maszyna UV laser markująca może służyć do grawerowania i cięcia?

Tak, maszyna UV laser markująca może wykonywać zarówno grawerowanie, jak i cięcie, w zależności od materiału i ustawienia mocy. Choć jest częściej używana do grawerowania ze względu na wysoką precyzję i minimalne wydzielanie ciepła, może również ciąć cienkie materiały, takie jak plastik i pokryte metale, przy odpowiednich ustawieniach.

1️⃣1️⃣ Jakie są wymagania konserwacyjne maszyny UV laser markującej?

Wymagania konserwacyjne maszyny UV laser markującej są stosunkowo niskie. Kluczowe zadania konserwacyjne obejmują:

- Regularne czyszczenie soczewek i luster w celu optymalnej wydajności.

- Regularna wymiana filtra powietrza, aby system pozostał zimny.

- Inspekcja źródła lasera pod kątem oznak zużycia lub uszkodzeń.

- Aktualizacje oprogramowania, aby zapewnić dostęp do najnowszych funkcji i ulepszeń.

1️⃣2️⃣ Jaki jest przedział cenowy maszyny UV laser markującej?

Cena maszyny UV laser markującej wynosi zazwyczaj od 10 000 USD do 40 000 USD, w zależności od modelu i konfiguracji. Czynniki takie jak moc, obszar znakowania i dodatkowe funkcje, takie jak system chłodzenia, mogą wpływać na ostateczną cenę.

1️⃣3️⃣ Czy maszyna UV laser markująca jest odpowiednia do produkcji na dużą skalę?

Tak, maszyna UV laser markująca jest zaprojektowana do obsługi produkcji na dużą skalę, oferując szybkie prędkości znakowania i długotrwałą wydajność. Jej trwała konstrukcja i niska potrzeba konserwacji sprawiają, że jest niezawodnym wyborem dla branż, które muszą przetwarzać duże ilości części w sposób konsekwentny.