آلة تعليم بالليزر CO2

February 22, 2025 /0 Comments/in Language /by linda

آلة تعليم بالليزر CO2

علامة سلسة على المواد غير المعدنية: أسرع، أنظف، وأكثر كفاءة من الليزرات الليفية

🔥 قم بتعزيز تعليمك باستخدام الليزر CO2! 🔥

هل تبحث عن تعليم غير معدني خالي من العيوب؟ توفر لك آلة تعليم الليزر CO2 دقة حادة للغاية على الخشب، والبلاستيك، والزجاج، وأكثر من ذلك – كل هذا بدون أي تلف حراري ونتائج تدوم طويلاً.

✨ لماذا تختار CO2؟ ✔ دقة متناهية – نقوش حادة ومفصلة في كل مرة

✔ خبير في المواد غير المعدنية – مثالي للأسطح العضوية والمغطاة

✔ متعدد الاستخدامات وسريع – من الأعمال الصناعية إلى المشاريع الإبداعية

✔ بُني لتدوم – علامات تظل حادة لسنوات

🚀 حدث لعبتك في التعليم اليوم!

طراز آلة تعليم بالليزر CO2

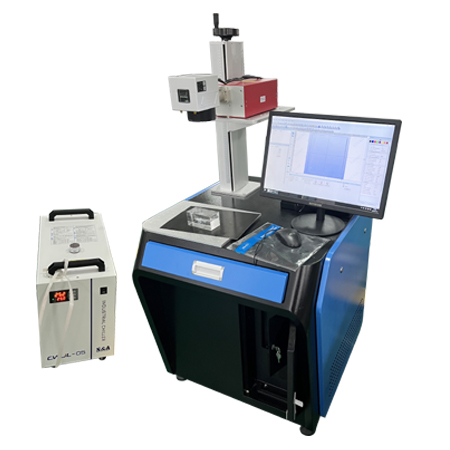

آلة وسم الليزر CO₂ الصغيرة

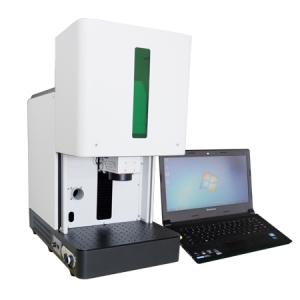

آلة وسم الليزر CO₂ المكتبية

هناك نوعان شائعان من آلات تعليم الليزر CO2: آلة تعليم الليزر CO2 المصغرة وآلة تعليم الليزر CO2 المكتبية.

آلة تعليم الليزر CO2 المصغرة

✅ مدمجة وقابلة للنقل – مثالية للأماكن الصغيرة أو عندما تحتاج إلى أخذ آلة تعليم الليزر CO2 معك أثناء التنقل

✅ إعداد سريع، نتائج كبيرة – مثالية للمشاريع الصغيرة التي تتطلب تعليم سريع وفعال

آلة تعليم الليزر CO2 المكتبية

✅ ثابتة وموثوقة – مثالية للاستخدام في المصانع أو المساحات الكبيرة

✅ مساحة عمل أكبر، إمكانيات أكبر – التعامل مع قطع أكبر بسهولة باستخدام تقنية تعليم الليزر CO2 المتقدمة

افتح دقة وقوة مع آلة تعليم الليزر CO2

هل تبحث عن تعزيز إنتاجك؟ آلة تعليم الليزر CO2 هنا لتأخذ قدرات النقش الخاصة بك إلى المستوى التالي. سواء كنت بحاجة إلى تعليم المكونات الإلكترونية، أو السلع الجلدية، أو المنتجات الخشبية، أو حتى الزجاج، توفر لك هذه الآلة الدقة، السرعة، والمتانة التي تحتاجها للبقاء في الصدارة في السوق التنافسي اليوم.

تستخدم آلة تعليم الليزر CO2 ليزر CO2 عالي القوة لنقش النصوص، والشعارات، والرموز الشريطية، وأرقام المسلسل، وحتى التصاميم المعقدة بدقة لا مثيل لها. سواء كنت تعمل مع أنماط معقدة أو علامات نصية بسيطة، ستنجز هذه الآلة المهمة بكفاءة ودقة، مما يضمن أن منتجاتك تظهر بمظهر احترافي وعالي الجودة في كل مرة.

المواصفات التقنية الرئيسية – لماذا تبرز آلة تعليم الليزر CO2

آلة تعليم الليزر CO2 ليست مجرد أداة أخرى في ورشتك—إنها استثمار في الجودة، السرعة، والدقة. إليك تفاصيل المواصفات التقنية التي تجعلها الخيار الأفضل لعملك:

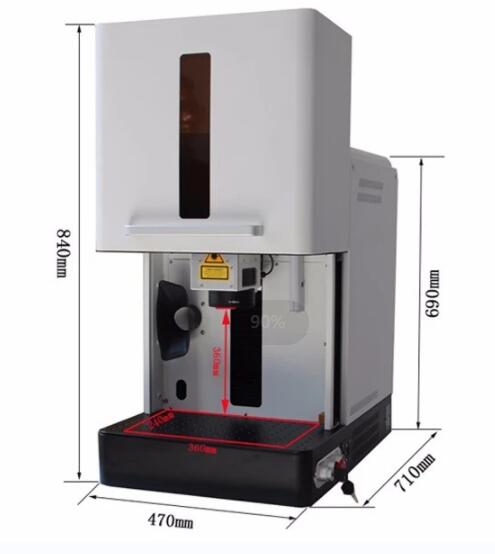

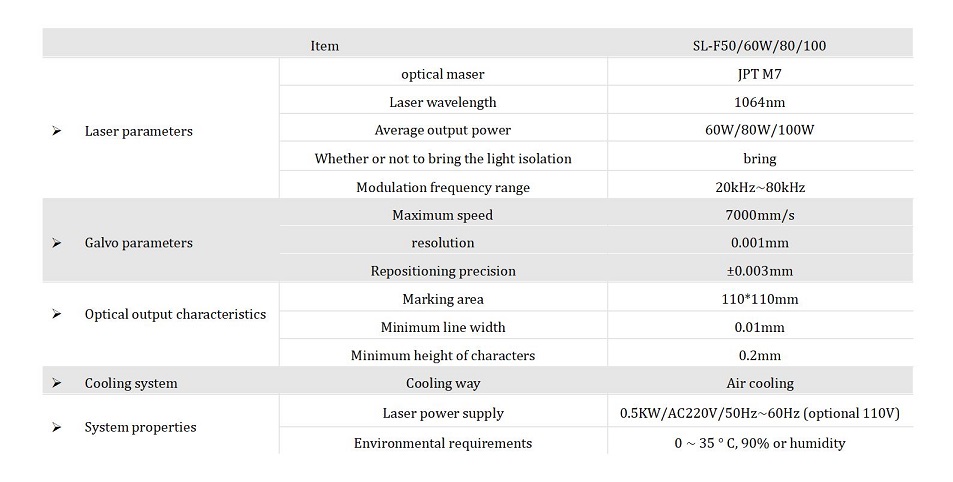

| المواصفة | التفاصيل |

|---|---|

| قوة الليزر | 30W / 50W / 100W (قابلة للتخصيص حسب الحاجة) |

| سرعة التعليم | تصل إلى 100,000 مم/ث (السرعة القصوى للتعليم عالي الكفاءة) |

| عمق التعليم | من 0.01 مم إلى 2 مم (العمق يختلف حسب المادة) |

| منطقة العمل | 100 مم × 100 مم، 200 مم × 200 مم، 300 مم × 300 مم (قابلة للتخصيص) |

| أصغر حجم حرف | 0.2 مم (نقش التفاصيل الصغيرة بدقة) |

| نظام التبريد | نظام تبريد مائي (يضمن التشغيل السلس والمستمر) |

التطبيقات—حول صناعتك مع تعليم الليزر CO2

إليك كيف تستخدم الصناعات آلة تعليم الليزر CO2 لتحويل سير العمل:

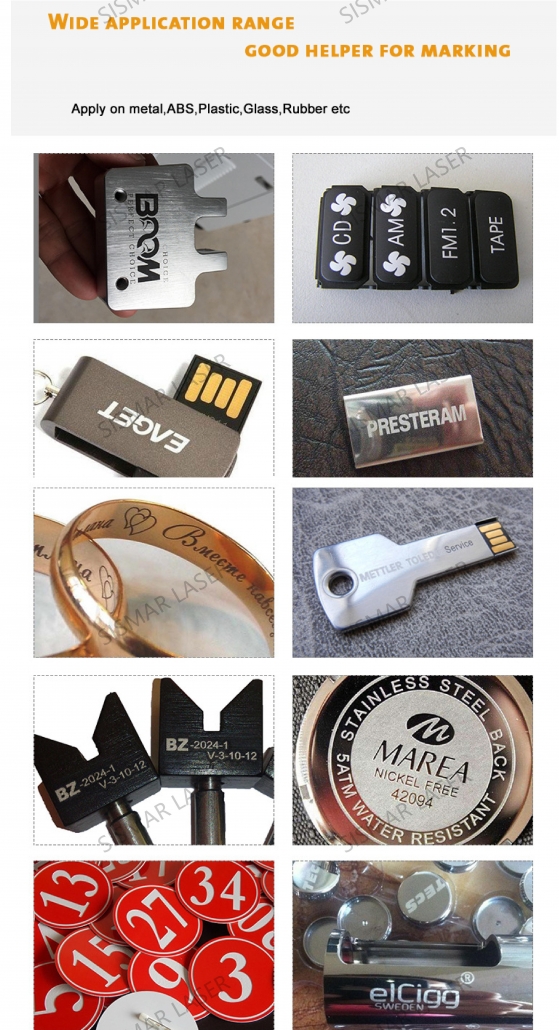

- الإلكترونيات: تعليم لوحات الدوائر، قطع الهواتف، والشواحن بدقة عالية ومتانة. لا داعي للقلق بشأن التلاشي أو البقع بعد الآن.

- الجلد: إنشاء تصاميم وشعارات مخصصة مذهلة على الحقائب، والأحذية، والأحزمة. ينقش الليزر بعمق للحصول على نتيجة دائمة.

- الخشب: من الأثاث إلى العناصر الزخرفية، النقش بتفاصيل حادة لإنشاء منتجات سيحبها عملاؤك.

- الزجاج: إضافة أنماط معقدة أو شعارات على المنتجات الزجاجية مثل الزجاجات، والنوافذ، أو القطع الزخرفية—كل ذلك بدقة ليزر CO2.

مهما كان المادة التي تعمل معها، ستعمل آلة تعليم الليزر CO2 على تحسين كفاءة الإنتاج، وجودة المنتج، وفي النهاية، خطك السفلي.

🚀 ميزات وفوائد آلة تعليم الليزر CO2

1. دقة لا مثيل لها

احصل على دقة لا تضاهى مع نقوش حادة وواضحة ومفصلة حتى على أصغر العناصر. مثالية للنصوص الدقيقة، والشعارات، والتصاميم المعقدة.

✨ الفائدة: تفاصيل مثالية في كل مرة.

2. متعددة الاستخدامات لجميع المواد

من البلاستيك إلى الخشب، والجلد، والزجاج، تتكيف هذه الآلة مع جميع احتياجاتك في تعليم المواد. دقة لا جهد فيها، بغض النظر عن السطح.

🔥 الفائدة: تعليم أي شيء بسهولة.

3. توفير المال والطاقة

حقق نتائج عالية الجودة مع استهلاك أقل للطاقة. تساعد هذه الآلة الفعالة في استهلاك الطاقة في تقليل تكاليف التشغيل.

⚡ الفائدة: استهلاك منخفض للطاقة لتحقيق توفير كبير.

4. مصممة لتدوم

تم تصميم آلة تعليم الليزر CO2 للعمل المستمر، مما يضمن أداءً موثوقًا على المدى الطويل. لا مزيد من القلق بشأن التآكل والتمزق.

💪 الفائدة: متينة ومبنية للعمل الشاق.

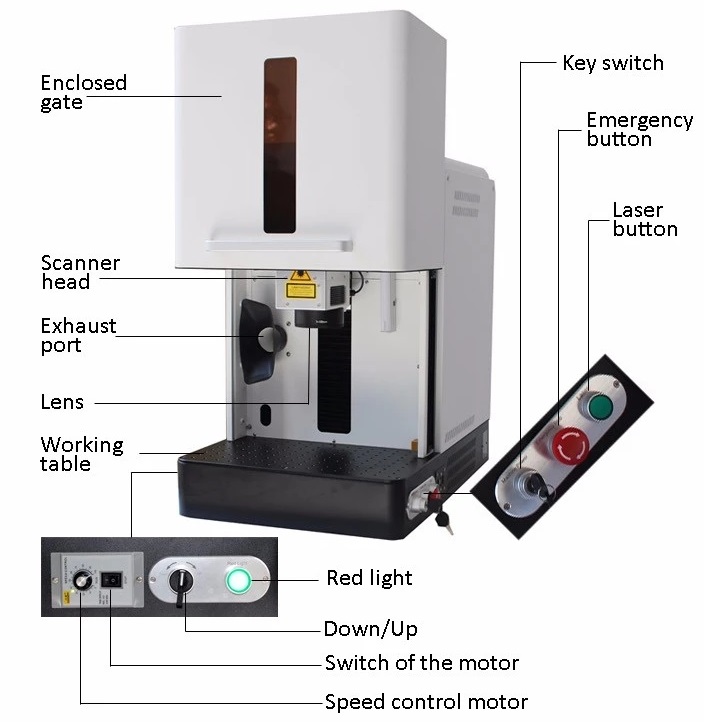

5. تشغيل سهل

بفضل واجهتها سهلة الاستخدام، يمكنك إعدادها وبدء التعليم في أي وقت. لا حاجة لتدريب معقد!

🔧 الفائدة: سهل الاستخدام، يمكنك البدء على الفور.

6. صيانة منخفضة، أداء عالٍ

تتطلب صيانة منخفضة. النظام الذاتي للتنظيف والأجزاء سهلة الاستبدال تضمن الأداء على المدى الطويل.

💰 الفائدة: صيانة منخفضة وعمر طويل.

لماذا تحتاج إلى آلة تعليم الليزر CO2؟

آلة تعليم الليزر CO2 هي أداتك المثالية لتحقيق الدقة، والكفاءة، والمتانة على المدى الطويل. إنها توفر لك المال، تعزز الإنتاجية، وتحقق نتائج من الدرجة الأولى، مما يجعلها استثمارًا مثاليًا لعملك.

📹 التطبيقات في العمل: شاهد آلة تعليم الليزر CO2 في العمل

1. عروض الفيديو ودراسات الحالة

شاهد آلة تعليم الليزر CO2 وهي تؤدي سحرها على مواد مختلفة. سواء كانت البلاستيك، الخشب، الجلد، الزجاج، أو المطاط، فإن الآلة تقدم نتائج خالصة في كل مرة.

شاهد كيف نقوم بنقش الشعارات المعقدة، التصاميم المخصصة، وملصقات الباركود بدقة عالية على الأسطح المختلفة.

💼 دراسة حالة عميل: تمكنت شركة رائدة في صناعة الأثاث الخشبي من زيادة إنتاجها بنسبة 40% باستخدام آلة تعليم الليزر CO2 لنقش النقوش المخصصة على قطع الأثاث الخاصة بهم. ساعدت سرعة الآلة ودقتها في تلبية المواعيد النهائية الضيقة دون التضحية بالجودة.

2. شهادات العملاء

لا تأخذ كلمتنا فقط—استمع إلى تجارب المستخدمين الحقيقيين مع آلة تعليم الليزر CO2:

⭐ “لقد غيرت هذه الآلة تمامًا الطريقة التي نعلم بها منتجاتنا. أصبح بإمكاننا الآن نقش الشعارات المخصصة على الخشب، الزجاج، والجلد بسرعة وبالدقة الاستثنائية. إنها سهلة الاستخدام ووفرت لنا الوقت والمال!”

— ليام ر.، مدير المنتجات في WoodWorks

⭐ “بصفتي مالكًا لعمل صغير، كانت آلة تعليم الليزر CO2 نقطة تحول حقيقية. لقد سمحت لي بتقديم منتجات جلدية مخصصة وهدايا مخصصة يحبها عملائي. الآلة موثوقة والنتائج دائمًا على مستوى عالٍ!”

— راشيل ت.، مؤسسة LeatherCraft

⭐ “نحن نستخدم آلة تعليم الليزر CO2 منذ عدة أشهر الآن، وأصبحت لا غنى عنها. سرعة التعليم مذهلة، وجودة النقش دائمًا دقيقة. لقد ساعد ذلك في تحسين سير العمل بشكل كبير.”

— ديفيد س.، مدير العمليات في LaserSolutions

1. ما هي آلة تعليم الليزر CO₂؟

آلة تعليم الليزر CO₂ هي أداة عالية الدقة تستخدم شعاع ليزر مركّز للنقش أو الحفر أو تعليم المواد غير المعدنية المختلفة. يتم استخدامها على نطاق واسع لإنشاء علامات دائمة وعالية الجودة على مواد مثل البلاستيك، والخشب، والجلد، والزجاج، وغيرها.

2. كيف تعمل آلة تعليم الليزر CO₂؟

تولّد الآلة شعاع ليزر مركّز يتفاعل مع سطح المادة، مما يؤدي إلى تبخر المادة أو ذوبانها أو خضوعها لتغيرات كيميائية. هذه العملية تخلق علامة دائمة دون الاتصال المادي، مما يضمن دقة وتفاصيل عالية.

3. ما هي المواد التي يمكن لآلة تعليم الليزر CO₂ معالجتها؟

آلات تعليم الليزر CO₂ مناسبة لمجموعة واسعة من المواد غير المعدنية، بما في ذلك:

- البلاستيك: مثل الأكريليك، PVC، والبولي كربونات.

- الخشب: بما في ذلك الخشب الرقائقي، MDF، والخشب الصلب.

- الجلد: سواء الطبيعي أو الصناعي.

- الزجاج: للنقش على الأواني الزجاجية والنوافذ.

- الورق: مثالية للتعليم على منتجات الورق والتغليف.

- المطاط: مناسبة لنقش الأختام والطوابع المطاطية.

- السيراميك: لإنشاء تصاميم على البلاط الفخاري والفخار.

- الأقمشة: مثل الأقمشة والملابس.

بالنسبة للمواد المعدنية، غالبًا ما يُتطلب استخدام آلة تعليم الليزر بالألياف.

4. ما هو جدول الصيانة لآلة تعليم الليزر CO₂؟

الصيانة المنتظمة أساسية لضمان الأداء الأمثل. يتضمن ذلك:

- يوميًا: تنظيف العدسات والمرايا لإزالة الغبار والحطام.

- أسبوعيًا: فحص وضبط تركيز الليزر والمحاذاة.

- شهريًا: فحص نظام التبريد واستبدال الفلاتر إذا لزم الأمر.

- سنويًا: إجراء فحص شامل وصيانة من قبل فني محترف.

الالتزام بإرشادات الشركة المصنعة يساعد على إطالة عمر الآلة والحفاظ على كفاءتها.

5. ما مدى دقة آلات تعليم الليزر CO₂؟

تقدم آلات تعليم الليزر CO₂ دقة عالية، قادرة على تحقيق تصاميم مفصلة ومعقدة. تعتمد الدقة على عوامل مثل جودة مصدر الليزر، ونظام التحكم، وحالة العدسات.

6. هل آلات تعليم الليزر CO₂ آمنة للاستخدام؟

نعم، عندما يتم تشغيلها بشكل صحيح، فإن آلات تعليم الليزر CO₂ آمنة. من المهم اتباع بروتوكولات السلامة، بما في ذلك ارتداء معدات الحماية المناسبة، وضمان التهوية السليمة، والالتزام بإرشادات السلامة من الشركة المصنعة.

7. ما هو عمر آلة تعليم الليزر CO₂؟

يختلف العمر الافتراضي حسب الاستخدام والصيانة. مع العناية السليمة، يمكن أن يدوم أنبوب الليزر بين 20,000 إلى 30,000 ساعة. تساعد الصيانة المنتظمة واتباع إرشادات التشغيل في إطالة عمر الآلة.

8. كيف أختار آلة تعليم الليزر CO₂ المناسبة لاحتياجاتي؟

ضع في اعتبارك العوامل التالية:

- توافق المواد: تأكد من أن الآلة قادرة على معالجة المواد التي تنوي العمل بها.

- منطقة التعليم: اختر آلة ذات منطقة تعليم تتناسب مع حجم منتجاتك.

- القوة والسرعة: القوة الأعلى تسمح بمعالجة أسرع، ولكن تأكد من توافقها مع احتياجات الإنتاج الخاصة بك.

- توافق البرمجيات: يجب أن تكون الآلة متوافقة مع برنامج التصميم الذي تستخدمه.

- الدعم والخدمة: اختر الشركة المصنعة التي تقدم دعمًا موثوقًا وخيارات خدمة.

استشارة متخصص في معدات الليزر يمكن أن يساعدك في اتخاذ قرار مستنير بناءً على احتياجاتك الخاصة.

مزيد من مقاطع الفيديو لآلة تعليم بالليزر CO2

اطلب عرض سعر لآلة تعليم بالليزر CO2

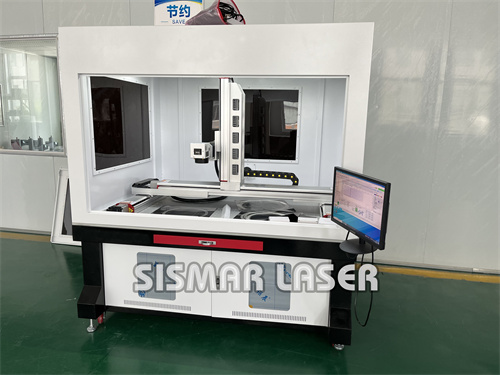

شركة SISMAR LASER تقدم حلولًا مبتكرة لآلات الليزر CO₂ وتطبيقات صناعية متنوعة

تتمتع شركة SISMAR LASER بمجموعة من آلات الليزر CO₂ والحلول المتقدمة التي تلبي احتياجات صناعية متعددة. سواء كنت تبحث عن ترقية لنظام تعليم الليزر الحالي أو اختيار ممتاز لجهاز الليزر الأول الخاص بك، فإن حلولنا تلبي جميع متطلباتك.

🔧 احصل على عرض سعر لآلة تعليم الليزر CO₂ عالية الجودة التي تتجاوز توقعاتك.

📅 يمكنك أيضًا تحديد موعد لعرض تجريبي لرؤية كيفية عمل آلة تعليم الليزر بالألياف.