آلة وسم الليزر الليفي 3D

February 20, 2025 /0 Comments/in Language /by linda

حلول وسم الليزر ثلاثية الأبعاد

آلات وسم الليزر ثلاثية الأبعاد الدقيقة للتطبيقات الصناعية

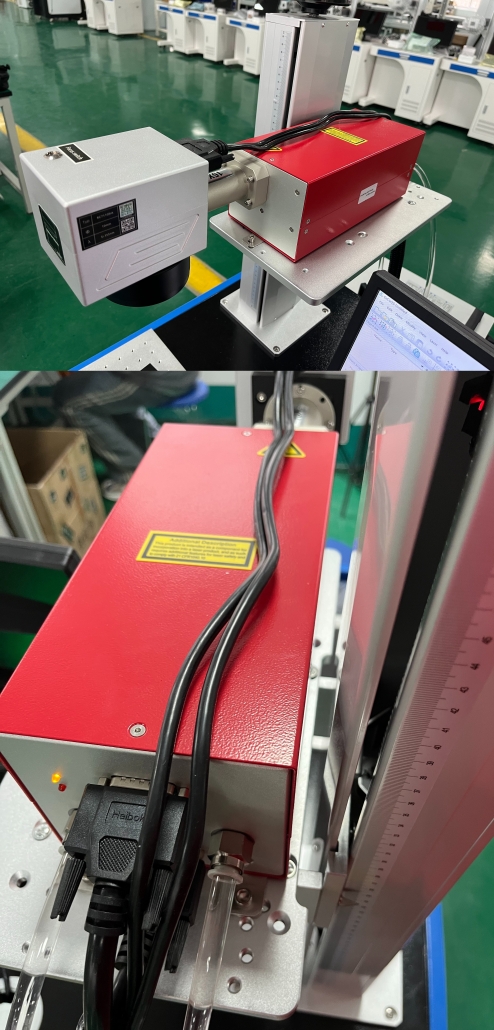

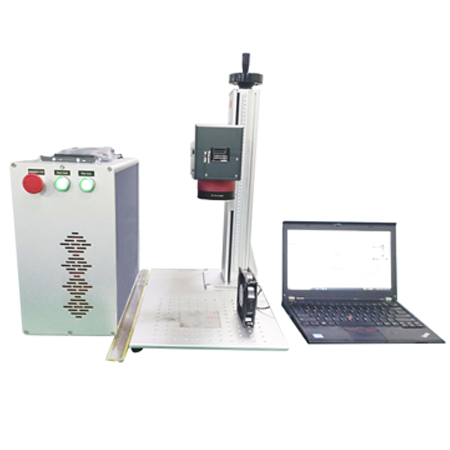

آلة وسم الليزر الليفي ثلاثية الأبعاد

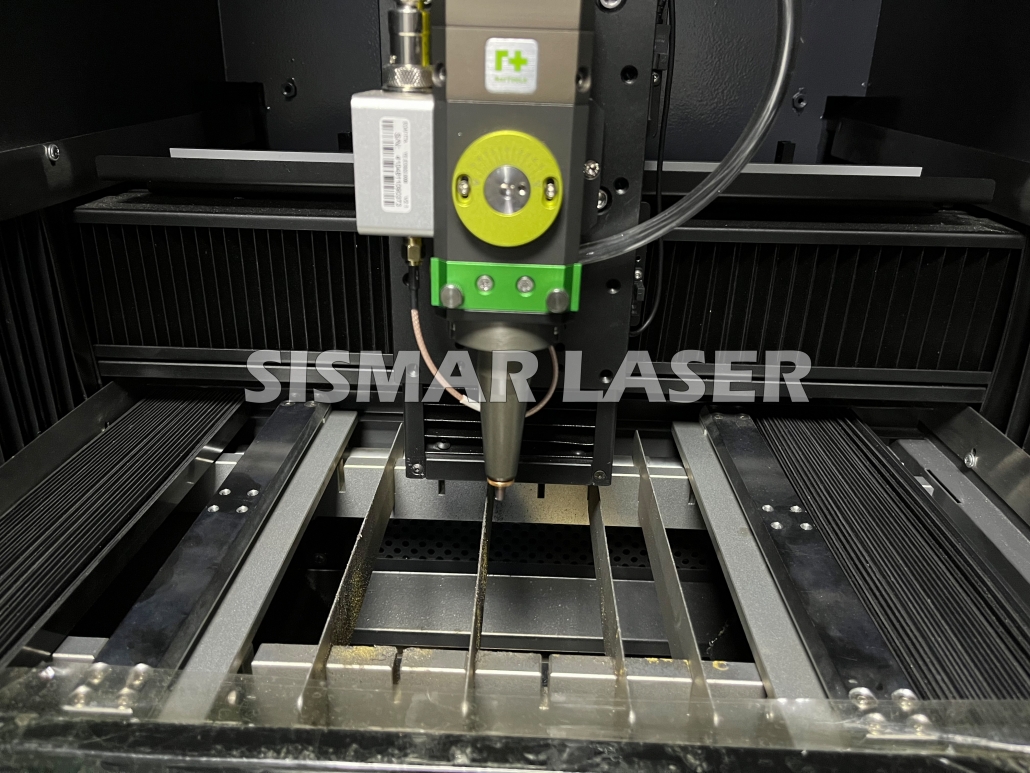

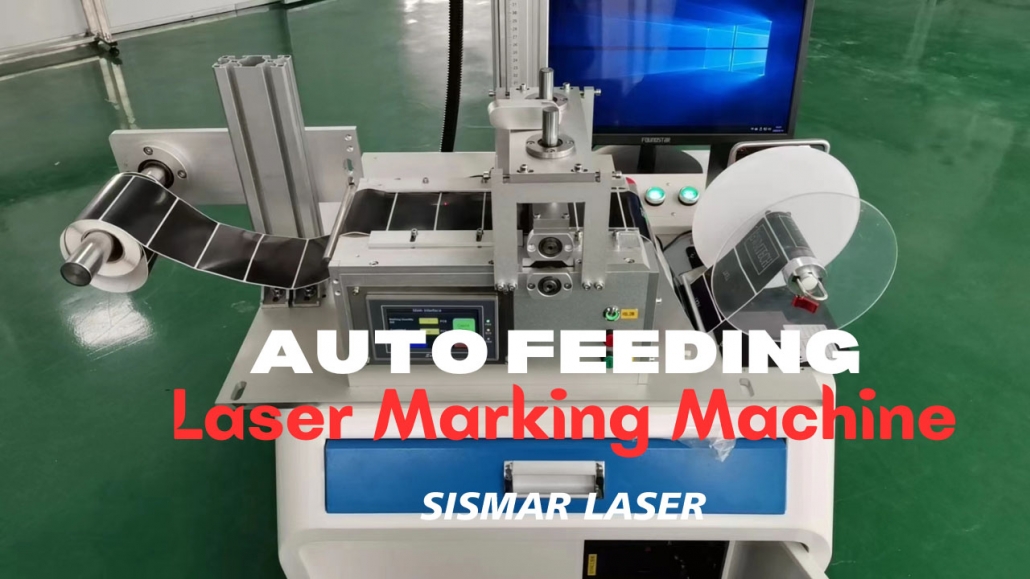

تُعد آلة وسم الليزر الليفي ثلاثية الأبعاد الحل النهائي للوسم على الأسطح المعقدة. تجمع هذه الآلة بين جميع فوائد نظام الليزر ثنائي الأبعاد وتضيف القدرة على الوسم على الأجسام الكروية، الأسطح المنحنية، وحتى الزوايا بزاوية 45 درجة. بفضل الدقة العالية وضبط التركيز الديناميكي، توفر هذه الآلة وسمًا مفصلًا ودائمًا على مجموعة واسعة من المواد، بما في ذلك المعادن، البلاستيك، والخزف.

🔹 الدقة الفائقة: تضمن آلة الوسم بالليزر الليفي ثلاثي الأبعاد تحقيق علامات دقيقة للغاية، مما يجعلها مثالية للصناعات التي تتطلب النقش بالليزر المتعدد الاستخدامات وعالي الجودة.

🔹 قوة التحمل: العلامات التي تتركها الآلة على المواد تكون دائمة، مما يجعلها مناسبة للاستخدام في بيئات عمل قاسية.

🔹 التنوع والإبداع: مع قدرة الوسم على الأسطح المعقدة والمستديرة، تتيح لك هذه الآلة ابتكار تصميمات متعددة واستثنائية.

هذه الآلة هي الخيار المثالي لجميع الصناعات التي تحتاج إلى وسم دقيق ومقاوم على مواد متنوعة.

نماذج آلات النقش والقطع بالليزر الليفي 3D

رفع قدراتك في الوسم والقطع مع تكنولوجيا الليزر ثلاثي الأبعاد

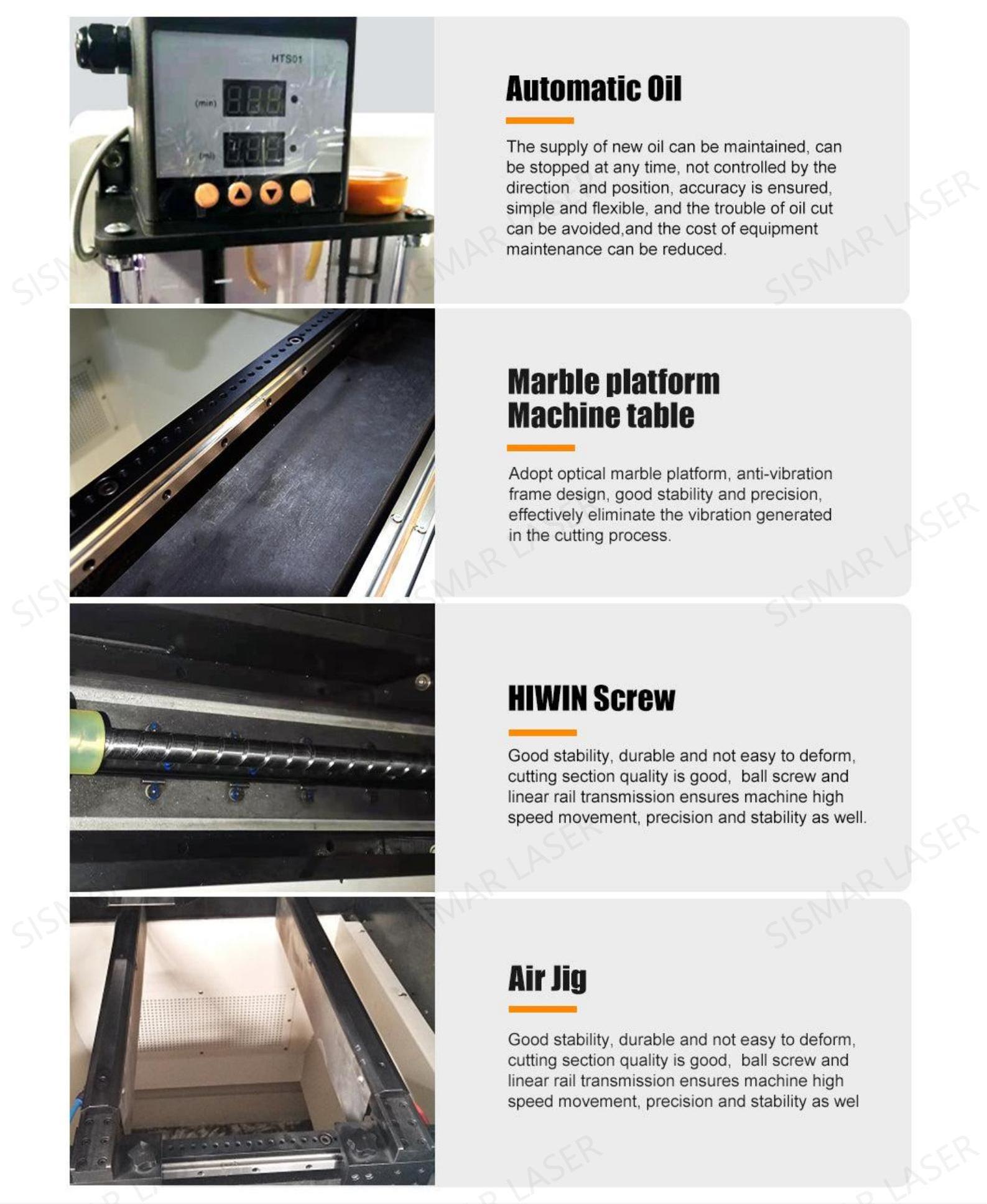

اكتشف أبعادًا جديدة في الدقة والكفاءة مع آلة وسم الليزر الليفي ثلاثي الأبعاد. مصممة للتعامل مع الأسطح المسطحة، التصاميم ثلاثية الأبعاد المعقدة، وحتى المواد الثمينة مثل الذهب والفضة، تقدم هذه الآلة تنوعًا وسرعة لا مثيل لهما.

الميزات الرئيسية:

🔹 وسم الأسطح المنحنية: قم بالوسم بسهولة على الأسطح المنحنية والأجسام الكروية بدقة استثنائية، متجاوزًا طرق الوسم الدوارة التقليدية.

🔹 النقش العميق ثلاثي الأبعاد: احصل على نقوش عميقة ومعقدة على مختلف المواد مثل المعادن، البلاستيك، والخزف بكل سهولة وكفاءة.

🔹 وسم بالليزر بتنسيق كبير: تعامل مع المشاريع الأكبر باستخدام منطقة وسم 300 مم × 300 مم للأسطح المسطحة وقدرة وسم منحني 150 مم × 150 مم × 60 مم، مما يضمن جودة ثابتة عبر الأسطح الواسعة.

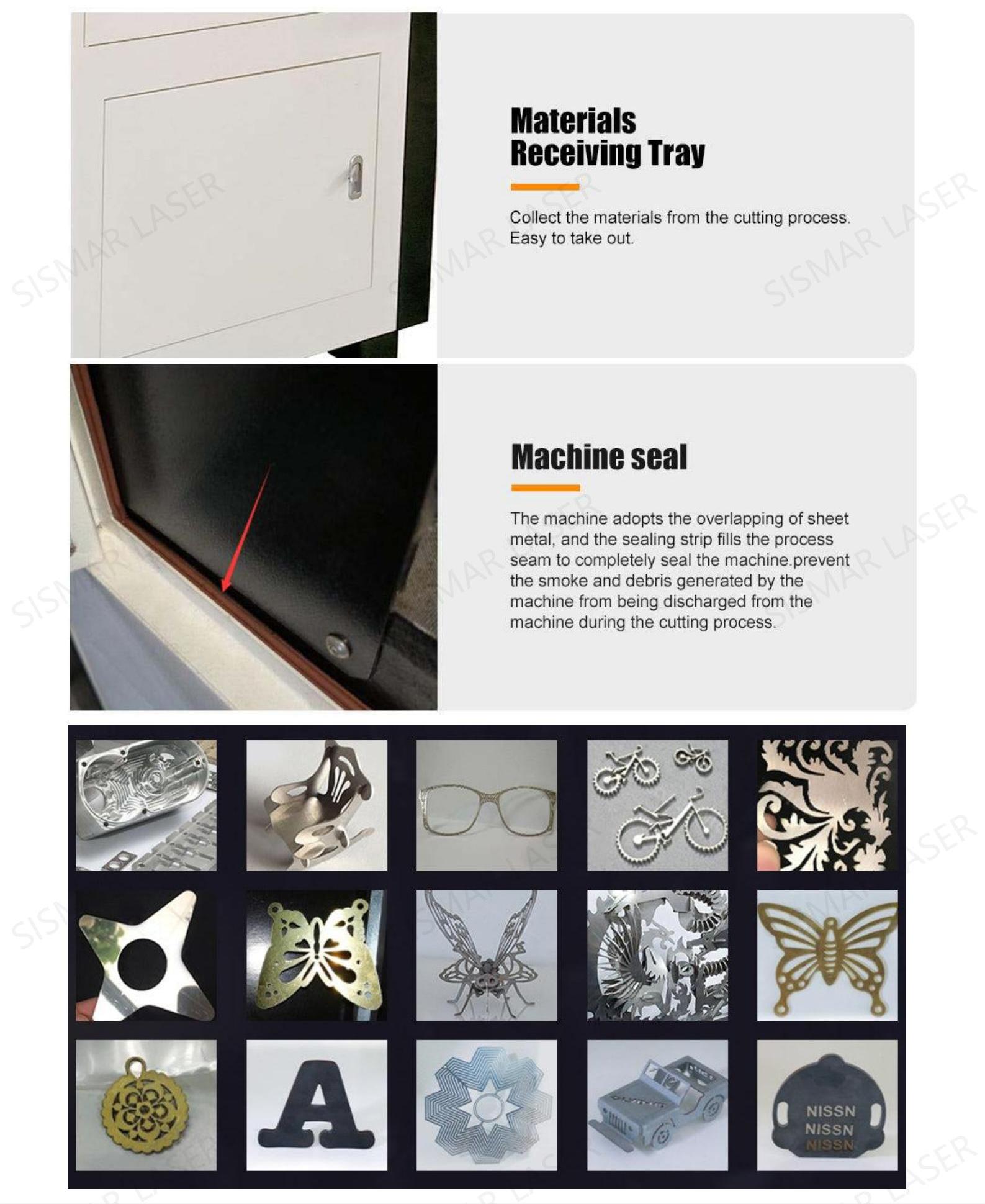

🔹 القطع بالليزر للمواد الثمينة: قطع الذهب، الفضة، والمعادن الثمينة الأخرى بدقة، مما يضمن قطعًا نظيفًا ومستويًا، مثاليًا لصناعة المجوهرات والتصاميم المخصصة.

المزايا مقارنةً بالوسم بالليزر ثنائي الأبعاد التقليدي:

🔹 تتبع التركيز الديناميكي: تتبع حقيقي للمنحنيات العميقة والمناطق المركزة، مما يضمن دقة متسقة عبر الأسطح المعقدة.

🔹 زيادة الكفاءة: اختبر سرعة محسّنة بشكل كبير دون التضحية بالجودة، مما يسهل عملية الإنتاج الخاصة بك.

🔹 أنماط وسم متعددة الاستخدامات: وسم على الأسطح المائلة، المخاريط الدائرية، الأسطح الكروية، والأشكال المنتفخة، مما يعيد تعريف قدرات الوسم التقليدية.

استكشف إمكانيات جديدة مع تكنولوجيا الليزر ثلاثي الأبعاد

احتضن مستقبل النقش والقطع مع آلة وسم الليزر ثلاثي الأبعاد. سواء كنت تقوم بإنشاء نقوش معقدة، أو وسم أسطح معقدة، أو قطع المعادن الثمينة، فإن هذه الآلة توفر دقة، سرعة، وتنوعًا لا مثيل لها. تخلص من قيود الوسم ثنائي الأبعاد التقليدي ورفع عملك إلى آفاق جديدة.

للمزيد من المعلومات أو لطلب عرض توضيحي، تواصل معنا اليوم.

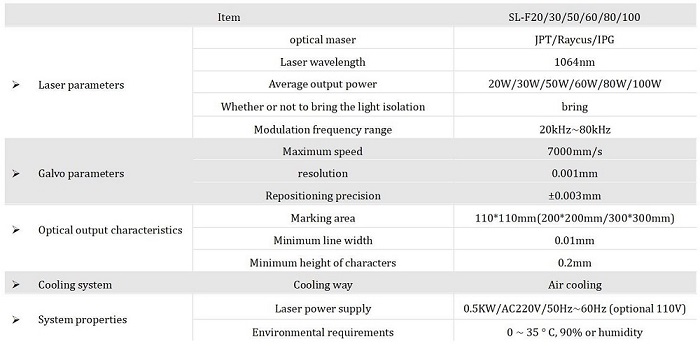

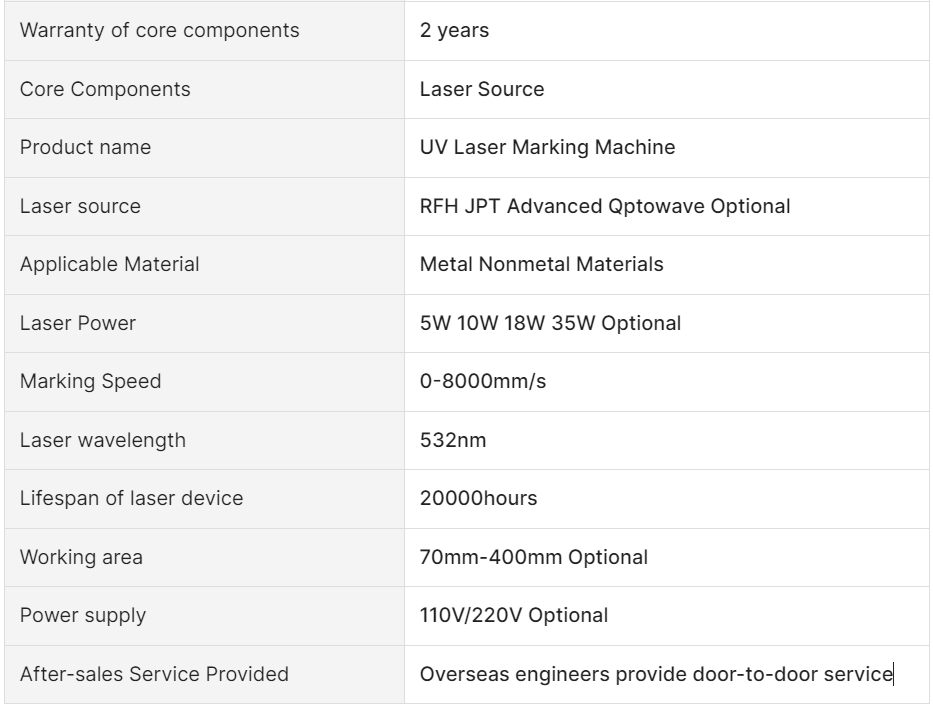

المواصفات الفنية لآلة وسم الليزر ثلاثي الأبعاد

| النموذج | SL-3D30W | SL-3D50W | SL-3D100W |

|---|---|---|---|

| القدرة الخارجة | 30W | 50W | 100W |

| القدرة النبضية | 1MJ | 1MJ | 1MJ |

| معدل التكرار | 30K-200KHZ | 50K-200KHZ | 50K-200KHZ |

| الطول الموجي | 1064nm | ||

| ليزر التوجيه | ضوء أحمر/655nm الطول الموجي/1.0mw خرج | ||

| نطاق الوسم | 140mm*140mm | ||

| نطاق الوسم الاختياري | 70mm70mm/100mm100mm/170mm170mm/200mm200mm/300mm≤400mm | ||

| نطاق الارتفاع/العمق | ±20mm | ||

| نموذج الوسم | التركيز الديناميكي لمحور XYZ | ||

| أقل عرض للخط | 0.03mm | ||

| سرعة الوسم | ≤10000mm/s | ||

| نظام التشغيل | WIN7/WINXP | ||

| الدعم الخطوط | نوع الخط الحقيقي، AUTOCAD، وغيرها | ||

| الرمز الشريطي أحادي البعد | CODE39/CODE128/TIF/CODABAR/EAN/UPC | ||

| الرمز الشريطي ثنائي البعد | QR/PDF417/DATA Matrix(ECC220) | ||

| دعم التنسيقات | PLT/DXF/DWG/SVG/STL/BMP/JPG/PNG/TIF | ||

| بيئة العمل | درجة الحرارة: 10℃-35℃ الرطوبة: 5%-75% | ||

| استهلاك الطاقة | 110v/220v اختياري/50-60HZ | ||

| طريقة التبريد | تبريد هوائي |

1. مقارنة بين أنواع آلات وسم الليزر:

| الخاصية | آلة وسم الليزر ثلاثية الأبعاد | آلة وسم الليزر ثنائية الأبعاد | آلة وسم الليزر 2.5D |

|---|---|---|---|

| مبدأ العمل | تستخدم تتبع التركيز الديناميكي، قادرة على الوسم على الأسطح المعقدة ثلاثية الأبعاد مثل الأسطح المائلة، الكروية، والمقعرة. | تُستخدم بشكل أساسي للأسطح المسطحة أو المنحنية البسيطة، ولا يمكنها التعامل مع الأشكال ثلاثية الأبعاد المعقدة. | مناسبة للوسم ثنائي الأبعاد والنقش المسطح، قادرة على التعامل مع بعض التأثيرات البسيطة للنقش البارز. |

| نوع السطح | يمكنها وسم الأسطح المسطحة، المنحنية، الكروية، المخروطية، وغيرها من الأسطح المعقدة ثلاثية الأبعاد. | فقط الأسطح المسطحة. | مناسبة للنقش البارز المسطح وبعض الأسطح المنحنية البسيطة. |

| التحكم في العمق | توفر التحكم في العمق، مثالية للنقش العميق ثلاثي الأبعاد والنقوش البارزة على الأسطح المنحنية. | مناسبة للنقش العميق التقليدي ولكن لا يمكنها إنشاء تأثيرات بارزة. | مناسبة للنقش البارز المسطح والنقش الضحل، توفر تأثيرات عمق مختلفة. |

| الدقة | دقة عالية، مثالية للنقوش المعقدة ثلاثية الأبعاد والنقوش البارزة على الأسطح المنحنية. | دقة عالية، مثالية للوسم المسطح والنقوش العميقة البسيطة. | دقة عالية، مناسبة للنقوش البارزة المسطحة وبعض النقوش البارزة ثلاثية الأبعاد الأساسية. |

| المواد | يمكن استخدامها على المعادن، البلاستيك، الخزف، وغيرها، خاصة للأسطح المعقدة والنقوش العميقة. | مناسبة للمعادن، البلاستيك، وغيرها، مثالية للوسم المسطح والنقوش العميقة. | مناسبة للمعادن، البلاستيك، الخزف، وغيرها، مثالية للنقوش البارزة المسطحة والنقوش الضحلة. |

| سرعة المعالجة | عمومًا أبطأ، مناسبة للمهام المعقدة مثل النقوش على الأسطح المنحنية والنقوش العميقة. | أسرع، مناسبة لمهام النقش العميق بكميات كبيرة. | سرعة معتدلة، مناسبة للنقوش البارزة المسطحة والنقوش الضحلة. |

| السيناريوهات التطبيقية | مثالية للنقوش البارزة على الأسطح المعقدة، النقوش العميقة، والوسم الدقيق في مجالات مثل المجوهرات، الطيران، المعدات الطبية، وغيرها. | مناسبة للنقوش العميقة التقليدية مثل وسم اللوحات البسيطة، الأدوات، والمنتجات الإلكترونية. | مثالية لتأثيرات النقش البارز المسطح، النقوش الفنية، الوسم الزخرفي، وغيرها. |

2. ملخص:

-

آلة وسم الليزر ثلاثية الأبعاد: قادرة على أداء جميع مهام آلة وسم الليزر 2.5D والنقوش البارزة على الأسطح المنحنية، مثالية للتطبيقات عالية الدقة، النقوش العميقة، والوسم على الأسطح المعقدة.

-

آلة وسم الليزر ثنائية الأبعاد: تستخدم بشكل أساسي لمهام النقش العميق المسطح، أسرع في السرعة، مناسبة لتطبيقات النقش العميق البسيط في الإنتاج الكبير.

-

آلة وسم الليزر 2.5D: تعالج الوسم ثنائي الأبعاد والنقوش البارزة المسطحة، مناسبة للنقوش المسطحة الدقيقة وبعض التطبيقات البارزة الأبسط.

جميع أنواع آلات وسم الليزر يمكن استخدامها لقطع ووسم الذهب والفضة، مما يتيح لك اختيار الآلة الأنسب وفقًا لاحتياجاتك الخاصة.

حوّل وسمك ونقشك مع تكنولوجيا الليزر ثلاثي الأبعاد!

تم تصميم آلة وسم الليزر ثلاثي الأبعاد للتعامل مع الأسطح المعقدة وتقديم نتائج عالية الدقة عبر مجموعة متنوعة من التطبيقات. من النقش المعقد على المجوهرات إلى مكونات الفضاء المتطورة، تعيد هذه الآلة تعريف الطريقة التي تعمل بها مع المواد. دعونا نستكشف أهم التطبيقات:

1. وسم ونقش المجوهرات 💍

دقة لكل قطعة تعد آلة وسم الليزر ثلاثي الأبعاد مثالية لتصميمات المجوهرات المخصصة. تتيح لك النقش بتفاصيل معقدة ووسم الأسطح المنحنية على الخواتم، القلائد، الأساور، وأكثر.

- تصاميم مخصصة على الأشكال الكروية، المسطحة والمعقدة.

- نقش أرقام التسلسل والشعارات بدقة عالية.

2. مكونات الفضاء والسيارات ✈️🚗

وسم الأجزاء المعقدة بسهولة سواء كنت تقوم بوسم شفرات التوربينات أو أجزاء المحرك، فإن آلة وسم الليزر ثلاثي الأبعاد تعالج المعلومات التفصيلية على الأسطح المعقدة.

- أرقام تسلسل وباركود على الأسطح المنحنية والمعقدة.

- نتائج عالية الجودة للمكونات الهامة في مجالات الفضاء والسيارات.

3. الأجهزة الطبية والمعدات 🏥

ضمان السلامة والامتثال في المجال الطبي، يجب أن يكون كل نقش دقيقًا وموثوقًا. تُستخدم آلة وسم الليزر ثلاثي الأبعاد لنقش أرقام التسلسل، الشعارات، وعلامات الأمان على الأدوات الطبية، الزرعات، والأجهزة التشخيصية.

- التتبع والامتثال للمعدات الطبية.

- النقش على الأسطح المنحنية أو الحساسة بدقة.

4. النقش الفني والمخصص 🎨

افتح خيالك يمكن للفنانين والمصممين إنشاء نقوش ثلاثية الأبعاد معقدة على مجموعة متنوعة من المواد مثل الخشب، الجلد، الزجاج، والمعدن. يجعل الليزر ثلاثي الأبعاد من السهل وسم الأنماط المخصصة والتصاميم الفنية.

- نقش تصاميم ثلاثية الأبعاد مفصلة مع وضوح استثنائي.

- مثالي لقطع الفن الشخصية والفريدة.

5. الإلكترونيات والميكروإلكترونيات 🔌

وسم المكونات الصغيرة بدقة للمكونات الصغيرة مثل PCB، أشباه الموصلات، والموصلات، توفر آلة وسم الليزر ثلاثي الأبعاد علامات لا تشوبها شائبة على المكونات الدقيقة.

- لا ضرر من المواد—مثالي للأجزاء الإلكترونية الحساسة.

- دقة عالية للنقوش المعقدة والصغيرة.

6. وسم الأدوات والقوالب 🛠️

وسم كل أداة وقالب بدقة في التصنيع الصناعي، يعد وسم الأدوات والقوالب بأرقام التسلسل، أرقام الأجزاء، والشعارات أمرًا بالغ الأهمية. تتعامل آلة وسم الليزر ثلاثي الأبعاد مع التفاصيل المعقدة على كل جزء.

- نتائج دائمة للمكونات الصناعية.

- مثالي للتتبع والتحكم في الجودة.

7. المكونات البصرية والعدسات 👓

نقش دقيق للمكونات البصرية سواء كنت تقوم بوسم العدسات، المرايا البصرية، أو الأدوات الدقيقة الأخرى، فإن آلة وسم الليزر ثلاثي الأبعاد توفر نتائج عالية الجودة.

- نقش الشعارات، الباركود، والقياسات الدقيقة.

- مثالي للأسطح البصرية المنحنية.

8. قطع المعادن والمواد الثمينة 💎

القطع الدقيق دون المساس بالجودة تعد آلة وسم الليزر ثلاثي الأبعاد مثالية لقطع الذهب، الفضة، والبلاتين بحواف نظيفة ومستوية.

- قطع دقيق للمنتجات الفاخرة والمجوهرات المخصصة.

- النقش والقطع للمعادن الثمينة دون إلحاق أي ضرر بالمادة.

9. اللوحات والعلامات المخصصة 🏷️

اجعل علامتك التجارية تبرز أنشئ لوحات أسماء، علامات، وملصقات مخصصة مع نقوش معقدة وتفاصيل عالية الدقة.

- تصاميم مخصصة للعلامات التجارية والتخصيص.

- وسم على مجموعة متنوعة من المواد بدقة عالية.

لماذا تختار آلة وسم الليزر ثلاثي الأبعاد؟

تعد آلة وسم الليزر ثلاثي الأبعاد الأداة المثالية للصناعات التي تتطلب الدقة، التنوع، والكفاءة. سواء كنت تقوم بوسم التصاميم المعقدة على المجوهرات، أو قطع المعادن الثمينة، أو نقش الأجزاء المعقدة في مجال الفضاء، فإن هذه الآلة تقدم نتائج مذهلة في كل مرة.

افتح إمكانيات جديدة مع تكنولوجيا الليزر ثلاثي الأبعاد—رفع مستوى وسمك ونقشك إلى آفاق جديدة اليوم! 🚀