Machine de gravure laser pour pierre série D

March 28, 2025 /0 Comments/in Language /by linda

Machine de gravure laser pour pierre série D

4o mini

“Déverrouillez la Précision et l’Efficacité avec la Machine de Gravure Laser CO2 Divisée : La Solution Ultime pour les Projets de Gravure sur Pierre et Personnalisés”

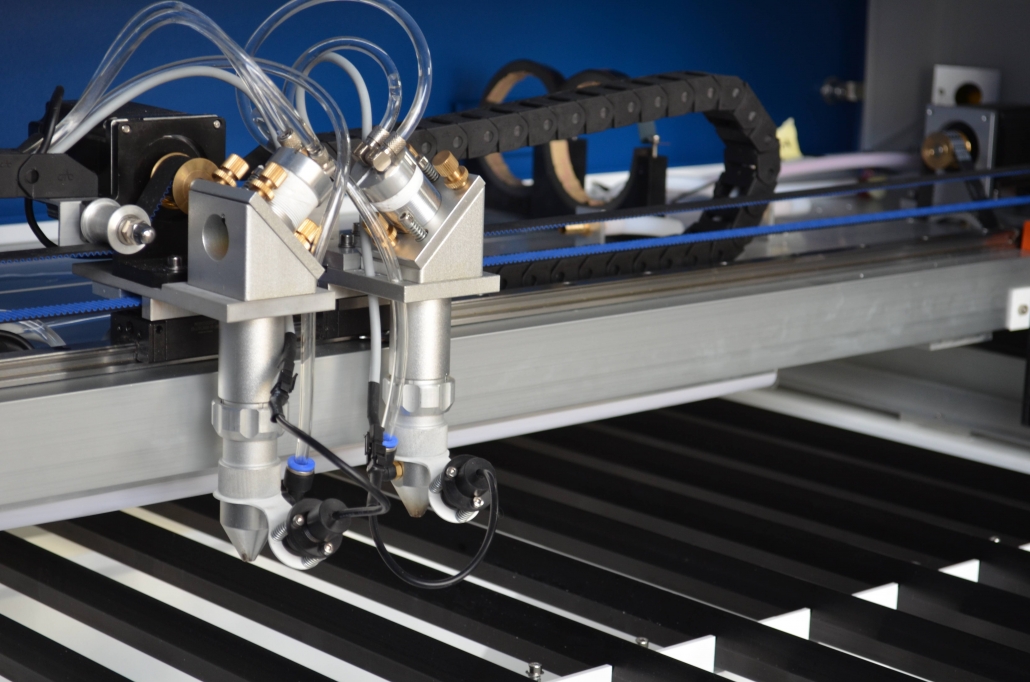

La machine de gravure laser CO2 divisée est une révolution pour les entreprises qui ont besoin de précision, de vitesse et de polyvalence dans leurs travaux de gravure. Contrairement aux machines traditionnelles, celle-ci possède un design divisé avec une partie supérieure et une partie inférieure qui peuvent être séparées pour une flexibilité maximale. Vous pouvez facilement retirer la partie supérieure et la placer directement sur des matériaux grands ou épais — parfaite pour les travaux de gravure difficiles sur pierre, bois ou acrylique.

Imaginez combien de temps vous gagnerez en n’ayant pas à déplacer des matériaux lourds. Ce design résout le problème de la capacité limitée de la plateforme, vous permettant de graver des matériaux lourds en toute facilité. Que vous soyez en train de sculpter des designs complexes sur des monuments en pierre, des pierres tombales ou des œuvres d’art personnalisées, la machine de gravure laser CO2 divisée garantit des gravures nettes et précises à chaque fois.

Grâce à son système de contrôle DSP avancé, vous obtenez des résultats rapides et de haute qualité qui feront passer votre entreprise de gravure au niveau supérieur. De plus, elle s’adapte dans des espaces restreints, ce qui en fait la solution idéale pour les ateliers ayant peu d’espace. Si vous êtes prêt à travailler plus intelligemment, et non plus durement — cette machine est l’amélioration que vous attendiez.

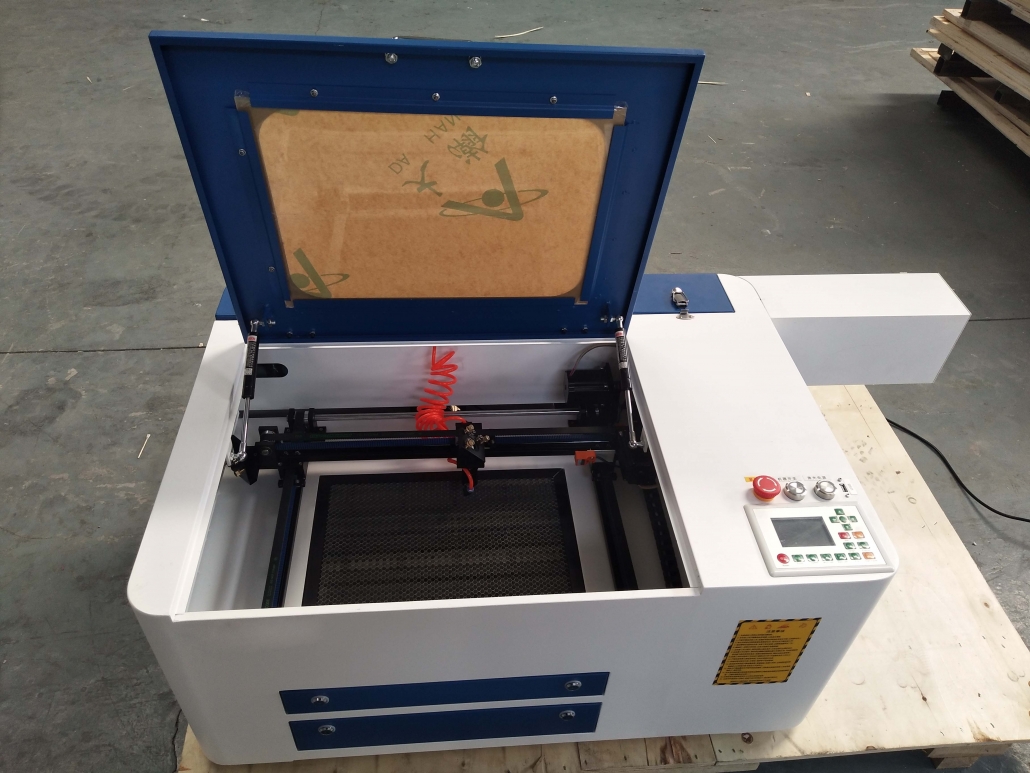

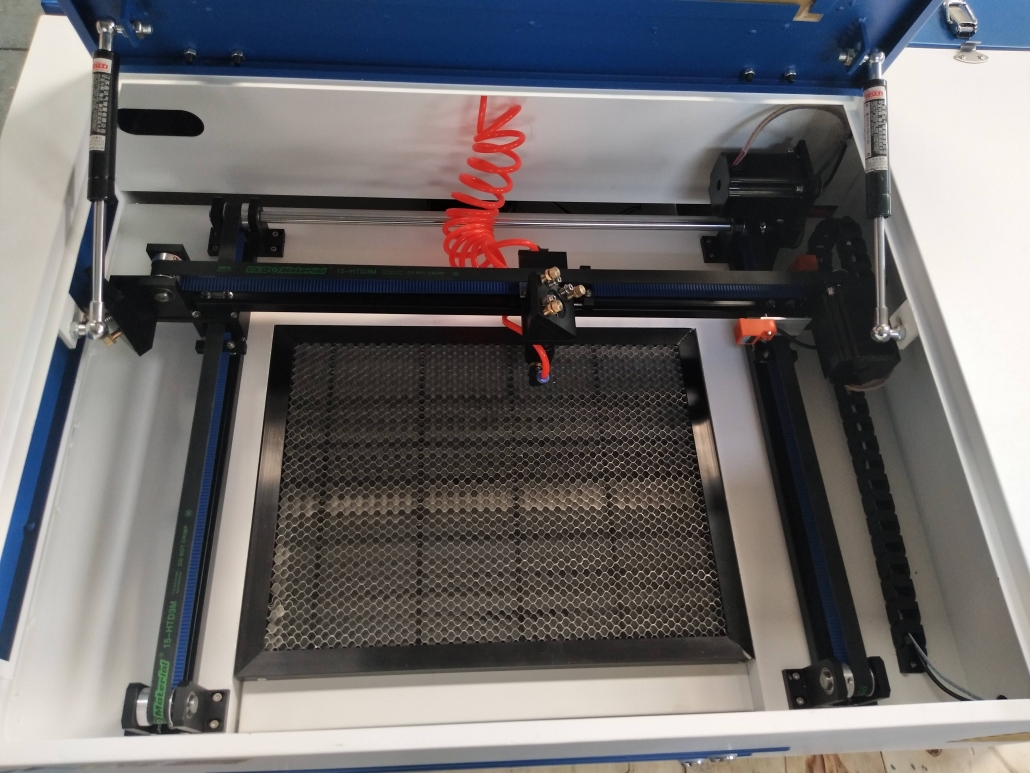

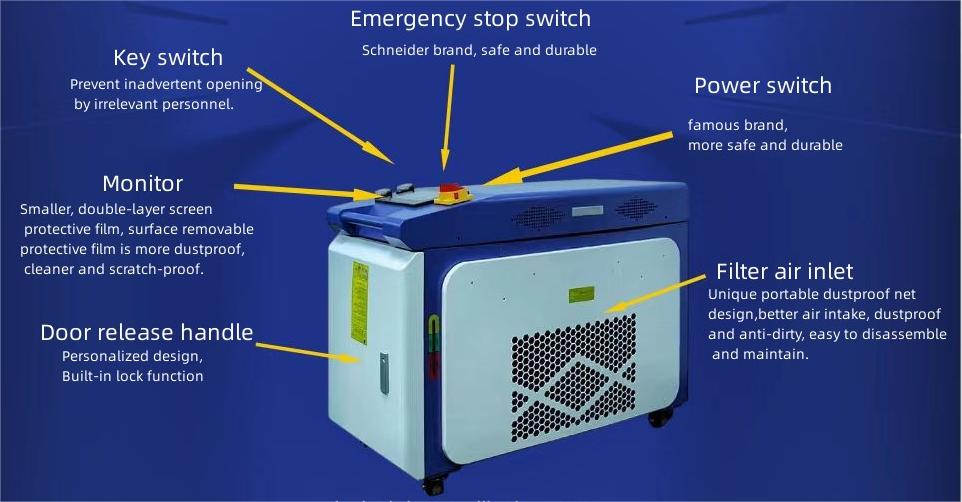

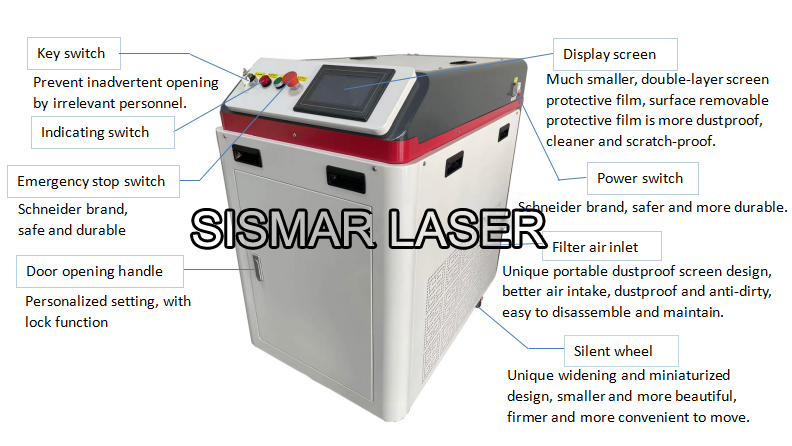

Photos de la machine de gravure et de découpe laser CO2 série XH

La machine de gravure laser pour pierre de type séparé : votre solution pour les sculptures sur pierre lourdes 🏛️

Êtes-vous fatigué de lutter avec des matériaux en pierre lourds qui ralentissent votre processus de gravure ? La machine de gravure laser pour pierre de type séparé est là pour révolutionner la façon dont vous manipulez les grandes sculptures en pierre. Conçue pour répondre aux besoins des entreprises du secteur de la gravure sur pierre, cette machine offre une flexibilité et une efficacité inégalées.

Voici pourquoi c’est l’outil ultime pour votre entreprise de gravure :

1️⃣ Design Modulaire pour une Flexibilité Maximale

La machine de gravure laser pour pierre de type séparé offre une flexibilité comme aucune autre ! Contrairement aux machines traditionnelles, sa partie supérieure est mobile et amovible, vous permettant de la placer directement sur de grands ou lourds matériaux en pierre.

-

Plus besoin de déplacer les pierres lourdes—la machine se déplace avec votre matériau.

-

Précision à portée de main—assurez une gravure précise à chaque fois.

Parfait pour les grands projets nécessitant une flexibilité maximale !

2️⃣ Surmontez les Limites des Plateformes Traditionnelles

Les machines de gravure traditionnelles ont souvent du mal avec les matériaux en pierre lourds en raison des limitations de capacité de la plateforme. Mais avec le design de type séparé, vous ne rencontrerez plus ces problèmes.

-

Plus besoin de soulever des pierres lourdes—placez simplement la partie supérieure sur le matériau en pierre et commencez la gravure.

-

Installation efficace—éliminez les limitations des plateformes traditionnelles qui ralentissent votre travail.

Cette machine rend la sculpture sur pierre lourde plus simple et plus efficace.

3️⃣ Gérez Facilement les Variations d’Épaisseur

Gérer des pierres de différentes épaisseurs a toujours été un défi. Ce n’est plus le cas ! Le design ajustable de cette machine vous permet de lever ou d’abaisser les parties supérieure et inférieure, garantissant ainsi un processus de gravure homogène.

-

Fonctionne avec toutes les épaisseurs—gravez des dalles épaisses et des gravures complexes avec facilité.

-

Résultats constants—plus de problèmes de profondeur de gravure inégale.

Vous pouvez maintenant aborder chaque projet sans vous soucier des variations d’épaisseur.

4️⃣ Parfait pour les Sculptures sur Pierre de Forte Intensité

La machine de gravure laser pour pierre de type séparé est spécialement conçue pour les projets de sculpture sur pierre lourds. Grâce à sa capacité à placer la partie supérieure directement sur le matériau, la gravure de grandes pierres devient un jeu d’enfant.

-

Pas de tracas avec les pierres lourdes—gravez des pierres grandes ou épaisses sans souci.

-

Expérience de gravure améliorée—concentrez-vous sur vos designs détaillés, pas sur le poids de la plateforme.

Paramètres de la machine de gravure laser CO2 séparée

| Spécification | Détails |

|---|---|

| Modèle de machine | Machine laser séparée SL-1390 1060 |

| Type de laser | Tube laser CO2 scellé, Longueur d’onde : 10,64 μm |

| Puissance laser | 60W / 90W / 100W |

| Mode de refroidissement | Refroidissement par eau circulante |

| Contrôle de la puissance laser | Contrôle logiciel de 0 à 100% |

| Système de contrôle | Système de contrôle hors ligne DSP, RDC6442S |

| Vitesse de gravure maximale | 60 000 mm/min |

| Vitesse de coupe maximale | 50 000 mm/min |

| Précision de répétition | ≤ ±0.01mm |

| Taille minimale des lettres | Chinois : 1,5 mm, Anglais : 1 mm |

| Taille de la table | 1000×600mm / 1300×900mm |

| Tension de travail | Monophasé 110V/220V, 50-60Hz |

| Conditions de travail | Température : 0-45°C, Humidité : 5%-95% |

| Logiciel de contrôleur | Anglais, Russe, Espagnol, etc. |

| Formats de fichiers pris en charge | *.plt, *.dst, *.dxf, *.bmp, *.dwg, *.ai, *.las, *.doc |

Pourquoi Choisir la Machine de Gravure Laser pour Pierre de Type Séparé ?

✔️ Design personnalisable : La partie supérieure peut être déplacée ou retirée pour un confort maximal.

✔️ Éliminer les restrictions de la plateforme : Plus besoin de vous inquiéter de la capacité de la plateforme.

✔️ Gérer les variations d’épaisseur : Ajustez facilement pour différentes épaisseurs de pierre.

✔️ Idéale pour les sculptures lourdes : Parfaite pour les projets de pierre grands et complexes.

Prêt à Transformer Votre Processus de Gravure sur Pierre ?

Ne laissez pas les matériaux en pierre lourds ou les variations d’épaisseur vous ralentir. La machine de gravure laser pour pierre de type séparé est la clé d’une gravure précise, flexible et efficace sur pierre.

Améliorez votre production aujourd’hui pour faire passer votre entreprise de gravure au niveau supérieur ! Découvrez l’efficacité de la gravure comme jamais auparavant ! 🚀

Applications de la machine de gravure laser CO2 séparée

La machine de gravure laser CO2 séparée est un outil polyvalent, idéal pour la gravure sur une large gamme de matériaux avec une grande précision, notamment dans les industries traitant des matériaux lourds ou épais.

1️⃣ Gravure sur Pierre

Parfaite pour la gravure sur pierre, granit, marbre et autres matériaux durs, idéale pour les pierres tombales, plaques commémoratives et pièces décoratives.

2️⃣ Monuments et Mémoriaux

Conçue pour la gravure de monuments, y compris les mémoriaux et tombes, offrant des gravures détaillées et de haute qualité.

3️⃣ Art de Pierre Sur-Mesure

Idéale pour créer des œuvres d’art en pierre personnalisées, y compris des sculptures et des œuvres murales avec des détails fins.

4️⃣ Bijoux et Articles Décoratifs

Utilisée pour graver des pierres précieuses, métaux et autres matériaux avec des designs complexes, logos et inscriptions personnalisées.

5️⃣ Gravure sur Bois

Adaptée pour la gravure du bois dans des projets personnalisés comme les meubles, enseignes et sculptures artistiques.

6️⃣ Gravure sur Verre et Acrylique

Gravez le verre et l’acrylique pour des récompenses personnalisées et des articles décoratifs avec clarté et netteté.

7️⃣ Applications Industrielles

Gravez des pièces métalliques, composants électriques et machines pour le marquage et la numérotation des séries en fabrication.

8️⃣ Publicité et Signalétique

Idéale pour créer des enseignes personnalisées, logos et supports de marque sur pierre, acrylique, bois et métal.

Pourquoi Choisir la Machine de Gravure Laser CO2 Séparée ?

✔️ Matériaux Polyvalents : Grave sur pierre, bois, métal, acrylique, verre et bien plus encore.

✔️ Robuste : Manipule facilement les matériaux lourds ou épais.

✔️ Précision : Réalise des gravures fines et détaillées.

✔️ Design Flexible : Facilité de manipulation des grands objets et des espaces étroits grâce au design séparé.

Parfaite pour les entreprises dans la gravure sur pierre, les bijoux, l’art sur mesure et le secteur industriel, la machine de gravure laser CO2 séparée améliore l’efficacité et la précision de vos gravures.

Machine de gravure et découpe laser séparée vs. Machine de gravure et découpe laser classique : Quelle est la différence ?

Lorsqu’il s’agit de choisir une machine de gravure et de découpe laser, plusieurs facteurs peuvent influencer votre prise de décision, tels que le design, la commodité et l’efficacité. Deux types populaires sur le marché sont la machine de gravure et découpe laser séparée et la machine de gravure et découpe laser classique. Examinons les principales différences entre ces deux options pour vous aider à faire un choix éclairé !

Voici un tableau comparatif entre la machine de gravure et découpe laser séparée et la machine de gravure et découpe laser classique pour mieux comprendre les différences :

| Caractéristique | Machine de gravure et découpe laser séparée | Machine de gravure et découpe laser classique |

|---|---|---|

| Design | Design séparé avec parties supérieure et inférieure pouvant être dissociées, offrant plus de flexibilité et de commodité. La partie supérieure peut être placée directement sur le matériau pour une gravure plus précise. | Design fixe, avec parties supérieure et inférieure intégrées. Plus rigide et adapté à la gravure de matériaux standards. |

| Manipulation des matériaux lourds et grands | Idéale : La partie supérieure peut être placée directement sur des matériaux lourds ou grands, éliminant le besoin de déplacer les matériaux. Parfaite pour la gravure de pierres ou matériaux lourds. | Limitée : Nécessite des outils supplémentaires pour déplacer les matériaux lourds, ce qui rend le traitement plus difficile pour les objets grands ou lourds. |

| Gestion des variations d’épaisseur | Les parties supérieure et inférieure peuvent être ajustées indépendamment, facilitant le travail sur des matériaux de différentes épaisseurs, garantissant une gravure stable. | Moins flexible pour gérer les variations d’épaisseur, nécessitant généralement des ajustements manuels et mieux adapté aux matériaux uniformes. |

| Adaptabilité à l’espace | Grâce à son design séparé, elle peut s’adapter facilement aux espaces restreints, idéale pour les ateliers avec un espace limité. | Nécessite généralement plus d’espace de travail, étant plus volumineuse et adaptée aux environnements spacieux. |

| Efficacité et commodité | Haute efficacité : la partie supérieure amovible réduit le temps passé à manipuler les matériaux et simplifie les opérations, surtout pour les projets de gravure lourds ou grands. | Moins d’efficacité : Nécessite plus de manipulation manuelle et d’ajustements, rendant l’opération plus longue, notamment pour les matériaux lourds. |

| Applications adaptées | Gravure sur pierre lourde, projets de gravure de grande envergure, industries nécessitant une flexibilité et un traitement précis de matériaux lourds ou grands. | Gravure standard, adaptée aux matériaux de taille moyenne à petite, sans nécessités particulières pour la manipulation de matériaux ou la variation d’épaisseur. |

| Prix | Plus élevé : en raison de sa flexibilité et de son design modulaire, elle est généralement plus chère, idéale pour les entreprises nécessitant un équipement haute performance. | Moins cher : généralement plus abordable, adaptée aux petites entreprises ou à celles traitant des tâches de gravure standards avec une complexité moindre. |

1️⃣ Flexibilité du Design

Machine de gravure et découpe laser séparée :

Le design séparé consiste en deux parties distinctes : la partie supérieure et inférieure de la machine. Cette structure modulaire permet une flexibilité accrue, notamment pour les matériaux lourds ou grands. La partie supérieure peut être retirée ou déplacée indépendamment, permettant de la placer directement sur les objets pour une gravure plus précise.

Idéale pour les entreprises ayant un espace limité ou traitant des matériaux lourds ou grands nécessitant de la flexibilité.

Machine de gravure et découpe laser classique :

La gravure laser traditionnelle a un design fixe, avec les parties supérieure et inférieure intégrées, rendant la machine plus rigide et moins adaptable lors de la manipulation de matériaux lourds ou grands.

Toute la machine est généralement stationnaire, ce qui rend parfois le chargement et le déchargement des matériaux plus difficiles, surtout pour les articles plus grands ou plus lourds.

2️⃣ Manipulation des matériaux lourds et grands

Machine de gravure et découpe laser séparée :

Grâce à la partie supérieure amovible, cette machine excelle dans la gestion des matériaux lourds ou grands. La capacité de placer directement la partie supérieure sur les matériaux sans les déplacer réduit l’effort et les risques de dommages pour les matériaux et la machine.

Parfaite pour les tâches de gravure lourdes, comme la pierre, le bois ou les métaux épais.

Machine de gravure et découpe laser classique :

Les gravures traditionnelles ne sont généralement pas conçues pour traiter efficacement les matériaux lourds ou grands. Déplacer des matériaux volumineux nécessite souvent du travail supplémentaire ou des équipements comme un chariot élévateur, ce qui est chronophage et coûteux en main-d’œuvre.

Mieux adapté pour les objets de taille moyenne ou petite où la manipulation des matériaux n’est pas un problème majeur.

3️⃣ Espace et Accessibilité

Machine de gravure et découpe laser séparée :

Le design séparé permet à la machine de s’adapter facilement aux espaces restreints, idéale pour les ateliers avec un espace limité. La possibilité de séparer les deux parties permet de la déplacer dans des zones autrement inaccessibles pour les machines classiques.

Parfaite pour les entreprises avec des portes étroites ou des environnements de travail compacts.

Machine de gravure et découpe laser classique :

Plus grande et plus volumineuse, la machine traditionnelle nécessite généralement plus d’espace, tant pour la machine elle-même que pour les matériaux. Ce design peut être restrictif, surtout pour les entreprises avec des contraintes d’espace ou des portes étroites.

Peut nécessiter un placement dans une zone d’atelier plus ouverte et spacieuse pour s’adapter à sa taille.

4️⃣ Gestion des variations d’épaisseur

Machine de gravure et découpe laser séparée :

L’une des caractéristiques remarquables du design séparé est la capacité de gérer facilement des matériaux de différentes épaisseurs. Les deux parties de la machine sont ajustables, ce qui vous permet de travailler sur des surfaces inégales ou des matériaux ayant des variations d’épaisseur importantes.

Cette fonction garantit une profondeur de gravure uniforme même sur des matériaux variant en hauteur.

Machine de gravure et découpe laser classique :

Bien que de nombreuses machines traditionnelles puissent traiter différentes épaisseurs de matériaux, les ajustements pour les variations d’épaisseur ne sont pas toujours aussi fluides. Les utilisateurs doivent souvent ajuster manuellement ou repositionner les matériaux, et parfois la plage de la machine peut être limitée, entraînant moins de flexibilité pour des gravures complexes ou inégales.

Moins adaptable pour des projets ayant des variations d’épaisseur significatives.

5️⃣ Efficacité et Commodité

Machine de gravure et découpe laser séparée :

Cette machine est conçue pour une efficacité maximale. La possibilité de déplacer facilement la partie supérieure ou d’ajuster la partie inférieure permet de passer moins de temps à déplacer les matériaux et plus de temps à graver.

Opération rationalisée et réduction de la main-d’œuvre, en particulier pour les projets de gravure lourds ou à grande échelle.

Machine de gravure et découpe laser classique :

Bien que les gravures traditionnelles soient fiables et efficaces, elles ne peuvent pas offrir le même niveau d’efficacité que la version séparée, surtout lors du traitement de matériaux lourds, grands ou ayant des variations d’épaisseur.

Nécessite plus de travail manuel et de gestion de l’espace, ce qui peut ralentir l’opération dans certaines situations.

6️⃣ Coût et Investissement

Machine de gravure et découpe laser séparée :

La flexibilité et le design modulaire rendent la machine séparée une option haut de gamme. Elle est généralement plus chère en raison de sa capacité à traiter des matériaux plus lourds et grands et de ses fonctionnalités d’économie d’espace.

Idéale pour les entreprises qui ont besoin d’investir dans un équipement haute performance pour des tâches lourdes.

Machine de gravure et découpe laser classique :

Plus abordable par rapport au design séparé, ce qui en fait une option attrayante pour les entreprises avec des tâches de gravure moins exigeantes.

Un bon choix si vos opérations se concentrent sur des matériaux plus petits et ne nécessitent pas la flexibilité d’un système séparé.

Quel modèle choisir ?

Optez pour la machine de gravure et découpe laser séparée si vous :

-

Travaillez régulièrement avec des matériaux lourds, grands ou de forme irrégulière.

-

Avez besoin d’une flexibilité supplémentaire dans votre processus de gravure.

-

Recherchez une machine pouvant s’adapter à des espaces plus petits et aux variations d’épaisseur des matériaux.

Choisissez la machine de gravure et découpe laser classique si vous :

-

Travaillez principalement avec des matériaux de taille petite à moyenne.

-

Avez moins d’espace et préférez une option plus simple et plus économique.

-

Ne nécessitez pas la flexibilité d’un design séparé.

Conclusion :

La machine de gravure et découpe laser séparée offre une flexibilité, une efficacité et des caractéristiques économisant de l’espace inégalées, ce qui la rend idéale pour les projets de gravure lourds et à grande échelle. En revanche, la machine de gravure et découpe laser classique est une solution fiable et rentable pour des tâches plus petites ou moins exigeantes. Les deux ont leurs avantages, mais le choix dépendra finalement de vos besoins professionnels et des types de matériaux avec lesquels vous travaillez.

FAQ : Machine de Gravure Laser CO2 Séparée

1️⃣ Qu’est-ce qu’une Machine de Gravure Laser CO2 Séparée ?

La Machine de Gravure Laser CO2 Séparée se distingue par son design unique qui permet de séparer les parties supérieure et inférieure de la machine. Cette conception offre une flexibilité accrue pour graver des matériaux plus grands ou plus épais avec facilité, ce qui la rend idéale pour des industries comme la gravure sur pierre, la création de bijoux et l’art personnalisé.

2️⃣ Quels matériaux la Machine de Gravure Laser CO2 Séparée peut-elle graver ?

Cette machine peut graver une grande variété de matériaux, notamment :

-

Pierre (granite, marbre, etc.)

-

Bois

-

Acrylique

-

Métal

-

Verre

-

Cuir

-

Tissu

3️⃣ Quel est l’avantage du design séparé ?

Le design séparé permet à la partie supérieure d’être mobile ou entièrement amovible, ce qui facilite la manipulation de matériaux lourds ou volumineux. Il permet également à la machine de s’adapter à des espaces restreints et simplifie la gravure d’objets avec des épaisseurs variées.

4️⃣ Comment la Machine de Gravure Laser CO2 Séparée gère-t-elle les matériaux épais ?

Le design séparé facilite le placement direct de la partie supérieure sur des matériaux épais comme la pierre, contournant ainsi les limites des machines de gravure traditionnelles. Les parties supérieure et inférieure peuvent être ajustées pour gérer des épaisseurs variées, garantissant des gravures précises et stables.

5️⃣ La Machine de Gravure Laser CO2 Séparée peut-elle être utilisée dans des espaces réduits ?

Oui, le design séparé est parfait pour les ateliers avec des portes étroites ou des espaces limités. Les parties supérieure et inférieure peuvent être utilisées séparément, permettant à la machine de s’installer dans des zones où les équipements conventionnels pourraient ne pas s’adapter.

6️⃣ La Machine de Gravure Laser CO2 Séparée est-elle facile à utiliser ?

Absolument ! La machine est équipée d’un système de contrôle DSP avancé, ce qui la rend conviviale et permet un fonctionnement à grande vitesse. Elle est également conçue pour un montage facile, vous faisant gagner du temps et améliorant votre flux de travail.

7️⃣ Quelles industries bénéficient de la Machine de Gravure Laser CO2 Séparée ?

La machine est largement utilisée dans les industries suivantes :

-

Gravure sur pierre (pierres tombales, monuments, sculptures)

-

Création de bijoux (gravure sur métaux, pierres précieuses)

-

Art personnalisé (œuvres d’art en pierre ou bois personnalisées)

-

Publicité (signalisation, logos, supports de branding)

-

Fabrication (pièces métalliques, numéros de série, marquage)

8️⃣ Comment la machine améliore-t-elle l’efficacité de la gravure ?

La Machine de Gravure Laser CO2 Séparée offre une gravure à grande vitesse, permettant aux entreprises de réaliser davantage de projets en moins de temps. Sa précision garantit des résultats de haute qualité, faisant d’elle un outil puissant pour améliorer la productivité et la production.

9️⃣ Quelles sont les exigences en matière de puissance pour la Machine de Gravure Laser CO2 Séparée ?

Les exigences en matière de puissance varient en fonction du modèle et de la taille, mais en général, la machine nécessite des sources d’alimentation industrielles standard. Pour des spécifications détaillées, veuillez consulter le manuel du produit ou contacter le fabricant.

🔟 Un support technique est-il disponible pour la machine ?

Oui, un support technique est fourni par le fabricant. Si vous rencontrez des problèmes, vous pouvez accéder à l’assistance client par e-mail, téléphone ou chat en direct. De plus, la machine est accompagnée d’un manuel d’utilisation complet pour le dépannage.

1️⃣1️⃣ Comment entretenir la Machine de Gravure Laser CO2 Séparée ?

Pour maintenir des performances optimales, nettoyez régulièrement la machine, en particulier les lentilles et miroirs. Assurez-vous que le système de refroidissement fonctionne correctement et vérifiez qu’il n’y a pas de pièces desserrées. Le fabricant peut également fournir des recommandations de maintenance supplémentaires spécifiques au modèle.

1️⃣2️⃣ Une formation est-elle disponible pour utiliser la machine ?

Oui, de nombreux fabricants proposent des sessions de formation pour les nouveaux utilisateurs, comprenant à la fois des ressources en ligne et une formation sur site. Cela garantit que vous tirez le meilleur parti de votre Machine de Gravure Laser CO2 Séparée.

Plus de vidéos de gravure et découpe laser

Demandez un devis pour une machine de gravure et découpe laser CO2

SISMAR LASER propose des solutions de gravure et découpe laser CO2 ainsi que d’autres équipements pour de nombreuses applications industrielles. Nos solutions peuvent servir de mise à niveau pour votre système de gravure et découpe laser CO2 existant ou être un excellent choix pour votre première machine laser.

Demandez un devis pour une machine de gravure et découpe laser CO2 de haute qualité qui dépassera vos attentes. Vous pouvez également planifier une démonstration pour découvrir comment fonctionne la machine de gravure et découpe laser CO2.

Bienvenue chez SISMAR LASER. Nous sommes ravis de répondre à toutes vos questions concernant nos machines de marquage/découpe laser à fibre.