Máquina de chorro de arena láser para espejos

February 17, 2025 /0 Comments/in Language /by linda

Máquina de Arenado Láser para Espejos de 1300*2500mm

Máquina de Grabado Láser para Espejos de Gran Formato

Máquina de Arenado Láser para Espejos: Tratamiento de Superficies Rápido, Limpio y Preciso

¿Buscas una máquina de arenado láser para espejos? Esta poderosa herramienta te ofrece acabados frosted perfectos en espejos y vidrio, además de ayudarte con la remoción de pintura, todo sin el desorden.

¿Por qué la necesitas?

- Precisión Láser: Obtén resultados suaves y consistentes cada vez.

- Rápida y Eficiente: Perfecta para producción a gran escala.

- Remoción de Pintura: Elimina recubrimientos y pintura sin causar daños.

- Ecológica: Sin polvo, sin productos químicos, solo trabajo limpio.

- Bajo Mantenimiento: Diseñada para durar con mínimo mantenimiento.

Si buscas una forma confiable de crear acabados frosted impresionantes y eliminar fácilmente la pintura de vidrio o espejos, esta es la máquina perfecta para ti.

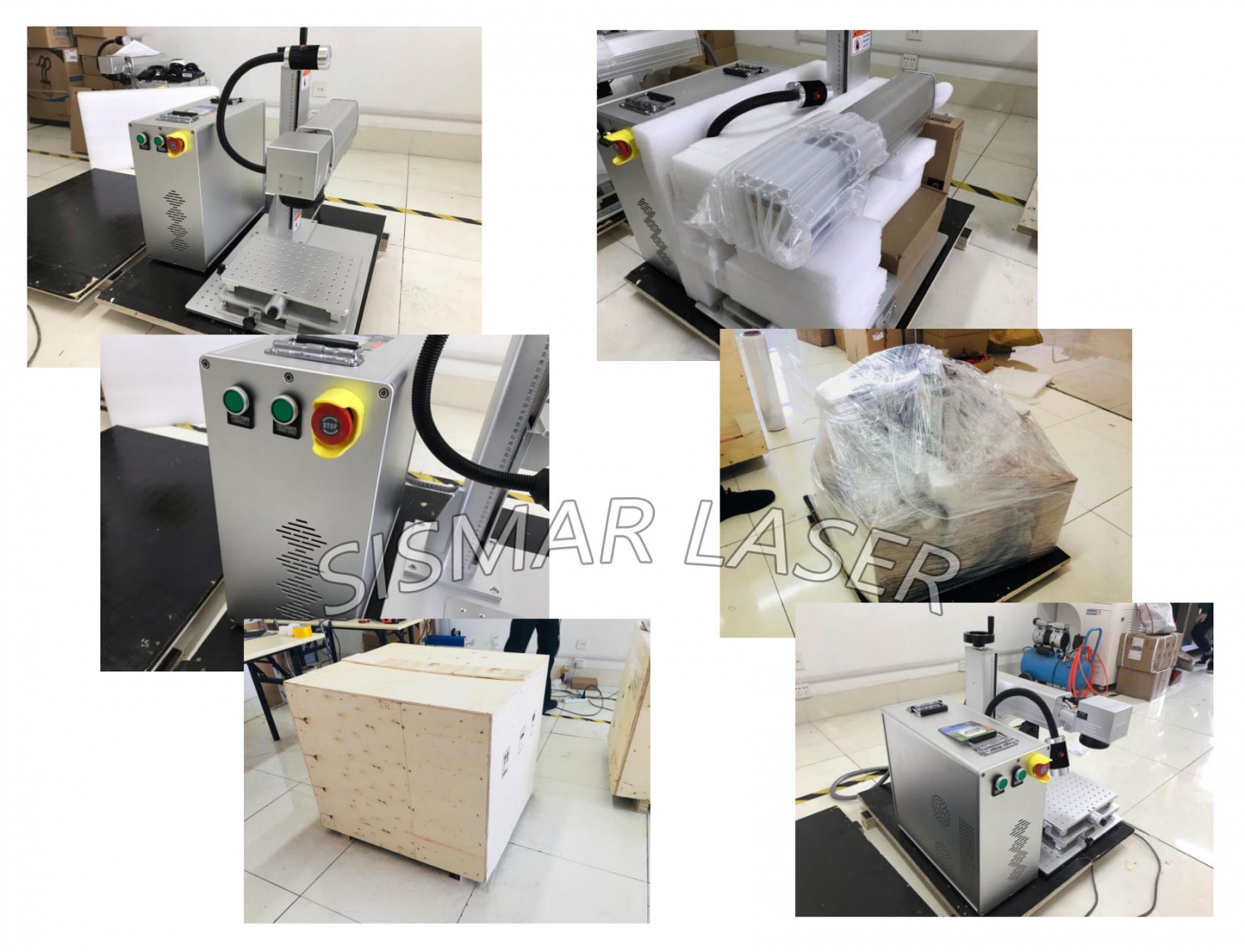

Fotos de la Máquina de Arenado Láser para Espejos

Máquina de Grabado y Perforación Láser en Espejos: La Solución Definitiva para Acabados Esmerilados, Eliminación de Recubrimientos y Perforación de Vidrio

La Máquina de Grabado y Perforación Láser en Espejos revoluciona el tratamiento de superficies de vidrio al combinar grabado láser, eliminación de pintura y perforación en un solo equipo potente. Logra acabados esmerilados impecables, elimina recubrimientos con eficiencia y perfora con precisión láser, sin el desorden de los métodos tradicionales.

🔹 ¿Cómo Funciona?

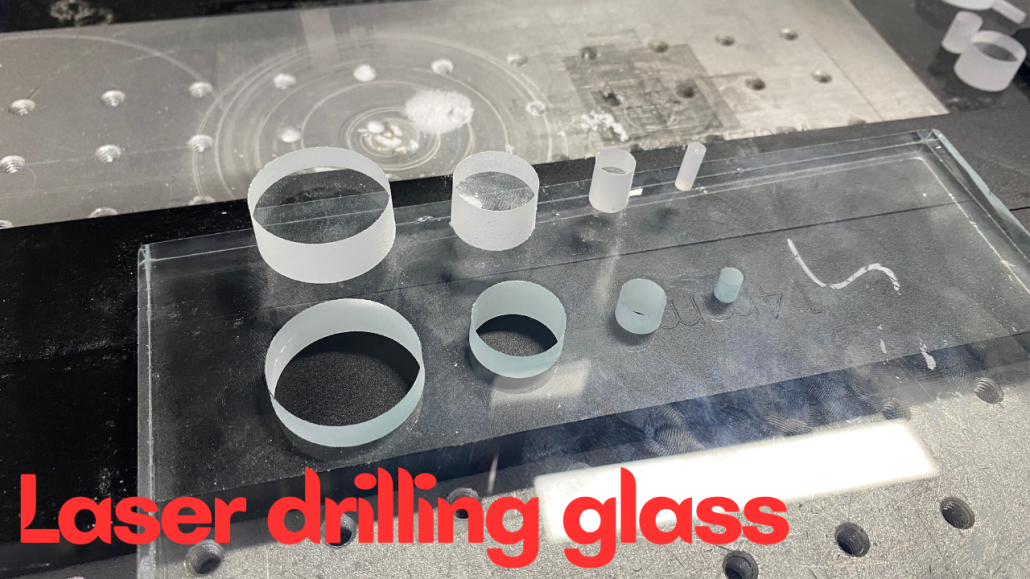

Nuestra máquina utiliza haces láser focalizados para eliminar pintura o recubrimientos de la superficie del vidrio, creando un efecto esmerilado uniforme y suave. Es perfecta para procesar espejos y vidrio decorativo, garantizando resultados precisos sin polvo ni productos químicos. Además, su funcionalidad integrada de perforación láser en espejos y vidrio permite realizar perforaciones y patrones con precisión extrema, ideal para diseños detallados.

🔹 Principales Características ✨

✅ Tecnología Todo en Uno: Combina grabado esmerilado, eliminación de pintura y perforación láser en una sola máquina.

✅ Precisión Láser Avanzada: Acabados homogéneos y detallados con perforaciones exactas para diseños sofisticados.

✅ Procesamiento Ecológico 🌱: Sin polvo ni químicos, un método limpio y seguro para el medio ambiente.

✅ Alta Velocidad de Producción 🚀: Optimiza la producción en grandes volúmenes con mínimos tiempos de inactividad.

✅ Bajo Mantenimiento 🔧: Diseño robusto y duradero, con mínimos requerimientos de mantenimiento.

Aquí tienes las especificaciones técnicas en formato de tabla:

| Especificaciones Técnicas | Detalles |

|---|---|

| 🔹 Nombre | Máquina de Grabado y Perforación Láser en Espejos |

| 📌 Potencia Láser | 120W / 200W |

| 📌 Tipo de Láser | Generador de fibra metálica de alta resistencia |

| 📌 Tamaño Máximo del Material | 1.5m x 3m (personalizable) |

| 📌 Materiales Compatibles | Espejo de plata, espejo de aluminio, espejo ecológico sin cobre, espejo de resina, etc. |

| 📌 Precisión del Procesamiento | 0.01mm |

| 📌 Velocidad de Procesamiento | 0-40m/min |

| 📌 Grosor del Material | 1-50mm |

| 📌 Método de Enfriamiento | Refrigeración por agua a temperatura constante |

| 📌 Sistema de Posicionamiento | Fijación de aluminio de cuatro estaciones |

| 📌 Peso Total | 1500 kg |

🎯 Aplicaciones Versátiles

🔹 Espejos inteligentes y decorativos con efectos esmerilados sofisticados.

🔹 Eliminación de pintura en vidrio sin dañar la superficie.

🔹 Perforaciones precisas para proyectos de diseño en vidrio.

Si buscas acabados esmerilados impecables, perforaciones precisas y una solución ecológica para el procesamiento de vidrio, la Máquina de Grabado y Perforación Láser en Espejos es tu mejor opción. 🌟

📞 Contáctanos hoy mismo para solicitar una demostración y descubrir su potencia en acción. 🚀

🚀 Por Qué el Pulido Láser para Espejos Inteligentes Revolucionará tu Negocio de Vidrio

¿Sigues atrapado en el pasado con chorro de arena tradicional o pintura esmerilada? Es hora de evolucionar. El Pulido Láser para Espejos Inteligentes está aquí para transformar la forma en que procesas el vidrio, ofreciéndote beneficios inigualables frente a los métodos obsoletos. Descubre cómo esta tecnología te ahorrará dinero, aumentará tu productividad y hará que tus productos destaquen.

✅ 1. Reduce Costos: Sin Consumibles, Sin Problemas

🔴 Chorro de Arena Tradicional: Gasto constante en abrasivos como polvo de diamante, arena y granallas. Es una inversión sin fin.

🟢 Pulido Láser: Sin consumibles. Es una inversión única que se amortiza sola. Reduces costos de materiales y minimizas desperdicios. Más ahorro = Más ganancias.

🏗 2. Un Espacio de Trabajo Más Limpio: Sin Polvo, Sin Desorden

🔴 Métodos Tradicionales: Nubes de polvo, residuos por todas partes y la necesidad de equipos de protección. Es un caos y un riesgo para la salud.

🟢 Pulido Láser: Sin polvo, sin escombros. Un proceso limpio y sin contacto que deja tu área de trabajo impecable. Ambiente más seguro y saludable para tu equipo.

🎯 3. Precisión Extrema: Perfecto en Cada Aplicación

🔴 Chorro de Arena: ¿Textura uniforme? Buena suerte… Los resultados son inconsistentes y muchas veces irregulares.

🟢 Pulido Láser: Precisión milimétrica para crear patrones intrincados, texturas complejas y acabados espectaculares en vidrio. Cero errores, cero retoques.

🔥 4. Resultados Duraderos: Belleza Que Perdura

🔴 Pintura Esmerilada: Al principio luce bien, pero con el tiempo se desvanece, se pela y requiere retoques constantes.

🟢 Pulido Láser: El acabado es permanente, resistente al desgaste y no se deteriora con el tiempo. Menos mantenimiento, clientes más felices.

⚡ 5. Ahorra Tiempo y Dinero: Automatización Máxima

🔴 Chorro de Arena: Proceso manual, lento y costoso con ajustes constantes.

🟢 Pulido Láser: Automatización total para tiempos de producción más rápidos, menores costos de mano de obra y máxima eficiencia.

🎨 6. Versatilidad Total en Cualquier Tipo de Vidrio

🔴 Chorro de Arena: No funciona bien en todos los vidrios y los resultados pueden variar.

🟢 Pulido Láser: Compatible con todo tipo de vidrio, desde espejos inteligentes hasta vidrio decorativo, arte y productos para el hogar. Además, se adapta a cualquier diseño sin esfuerzo.

🚀 El Futuro del Procesamiento de Vidrio Está Aquí

Si estás cansado de métodos sucios, ineficientes y obsoletos, es hora de dar el salto al Pulido Láser para Espejos Inteligentes. Es más rápido, limpio, preciso y duradero.

💰 Ahorra costos

⚡ Aumenta tu producción

🎯 Logra acabados impecables

🔥 No te quedes atrás. Adopta la tecnología láser y lleva tu negocio de vidrio al siguiente nivel. 🔥

❓ Preguntas Frecuentes (FAQ)

1️⃣ ¿Para qué se utiliza la Máquina de Arenado Láser para Espejos?

La Máquina de Arenado Láser para Espejos se usa principalmente para crear acabados de espejo, realizar arenados en superficies y eliminar pintura de metal, vidrio y otros materiales. Permite obtener superficies lisas y brillantes, además de eliminar recubrimientos como pintura, óxido y capas de óxido.

2️⃣ ¿Puede esta máquina eliminar pintura de cualquier superficie?

✅ Sí, la Máquina de Arenado Láser para Espejos es altamente efectiva para eliminar pintura de metal, vidrio, plástico y piedra. Es ideal para decapado de pintura, limpieza de superficies y restauración sin dañar el material subyacente.

3️⃣ ¿Qué tipos de materiales pueden tratarse con esta máquina?

🔹 Metal, vidrio, plástico, piedra y cerámica.

🔹 Ideal para industrias como automotriz, construcción, restauración de arte y metalurgia, donde el tratamiento de superficies y la eliminación de pintura son esenciales.

4️⃣ ¿Cómo crea un acabado tipo espejo?

La máquina usa tecnología láser avanzada para realizar el arenado de superficies, logrando un acabado reflejado, liso y brillante. Ajustando la configuración del láser, se pueden obtener diferentes niveles de brillo o acabado mate según las necesidades del proyecto.

5️⃣ ¿Deja residuos o daña la superficie?

🚫 No, la máquina está diseñada para ser precisa y delicada. Su sistema de arenado láser no genera residuos ni daña el material tratado. Además, el proceso de eliminación de pintura es no abrasivo, garantizando la integridad de la superficie.

6️⃣ ¿Qué tan efectiva es para eliminar pintura?

🛠 Extremadamente eficiente. Puede eliminar capas de pintura, óxido y oxidación de piezas automotrices, estructuras metálicas, equipos industriales y maquinaria sin afectar el material base.

7️⃣ ¿Es adecuada para uso industrial?

✅ Sí, está diseñada para cumplir con los requisitos industriales y manejar proyectos de gran escala con alta eficiencia. Es ideal para sectores como automotriz, construcción, manufactura y restauración de arte.

8️⃣ ¿Cómo funciona el proceso de eliminación de pintura?

La máquina utiliza ablación láser, donde el haz láser descompone la pintura o el recubrimiento sin químicos ni abrasivos. Es un proceso ecológico y seguro para múltiples entornos.

9️⃣ ¿Es fácil de operar?

🖥 Sí, cuenta con una interfaz intuitiva que permite ajustar potencia, velocidad y frecuencia del láser, facilitando su uso incluso para principiantes.

🔟 ¿Qué mantenimiento requiere?

🔧 Mantenimiento mínimo:

✔ Limpieza regular de la lente.

✔ Revisión del sistema láser.

✔ Mantenerla en un área bien ventilada para un rendimiento óptimo.

1️⃣1️⃣ ¿Cuál es la vida útil de la máquina?

🔹 Larga duración con el mantenimiento adecuado.

🔹 Su sistema láser está diseñado para uso continuo y alto rendimiento durante muchos años.

1️⃣2️⃣ ¿Cuánta energía consume?

⚡ El consumo varía según el modelo y material tratado, pero la tecnología láser es más eficiente energéticamente que los métodos abrasivos tradicionales, reduciendo los costos operativos.

1️⃣3️⃣ ¿Puede trabajar con diseños detallados o áreas intrincadas?

🎨 Sí, la máquina permite alta precisión en grabados y arenados, logrando detalles finos para aplicaciones exigentes.

1️⃣4️⃣ ¿Es ecológica?

🌱 ¡Absolutamente! La máquina elimina la necesidad de químicos y abrasivos utilizados en el arenado y eliminación de pintura convencional. Además, genera menos residuos, promoviendo un entorno más limpio y sostenible.

🚀 Optimiza tus procesos con la Máquina de Arenado Láser para Espejos y lleva tu producción al siguiente nivel.