Machine de Marquage Laser Volante : La Solution Ultime pour un Marquage Rapide et Précis ✨

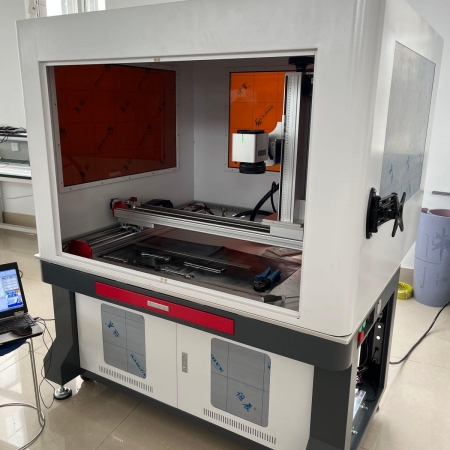

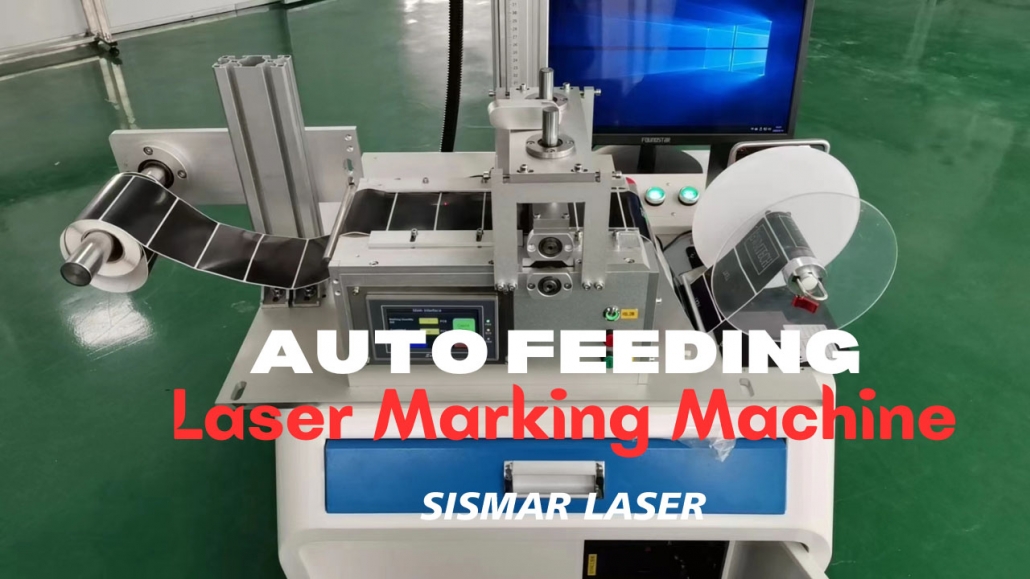

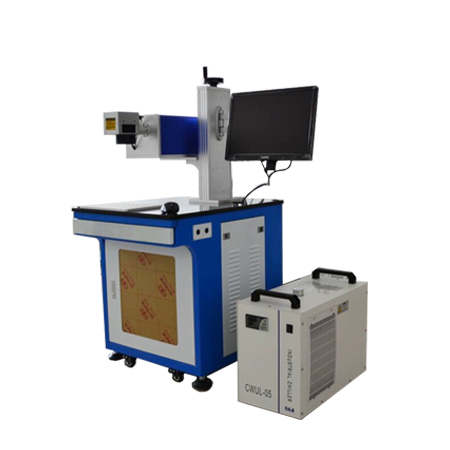

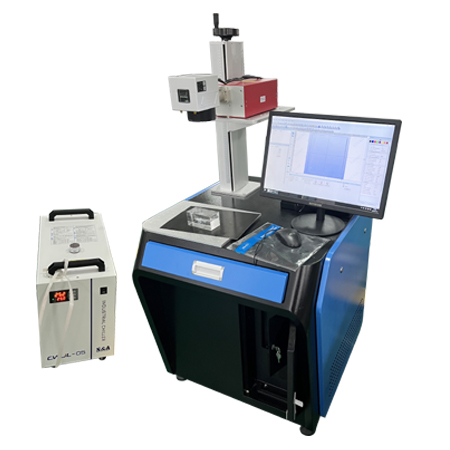

Vous recherchez un marquage précis à grande vitesse qui maintient votre production sans interruption ? La Machine de Marquage Laser Volante est la technologie innovante que vous attendiez. Cette machine puissante est conçue pour marquer divers matériaux tels que les métaux, les plastiques et les composites avec une précision et une vitesse incomparables, ce qui en fait le choix idéal pour des secteurs comme l’électronique, l’automobile et l’emballage.

1️⃣. Qu’est-ce que la Machine de Marquage Laser Volante ? 🔍

La Machine de Marquage Laser Volante est un système laser de pointe conçu pour marquer en continu les produits lorsqu’ils passent sur la ligne de production. Contrairement aux machines laser traditionnelles qui nécessitent des pièces fixes, ce système laser volant fonctionne sur une cible dynamique et mobile, ce qui en fait le choix parfait pour une fabrication à grande vitesse.

2️⃣. Caractéristiques Clés et Avantages :

| Caractéristique |

Description |

| 2.1 Fonctionnement Continu Sans Interruption ⏩ |

La Machine de Marquage Laser Volante fonctionne à pleine vitesse, marquant les produits en temps réel lorsqu’ils traversent le système. Ce fonctionnement continu élimine les temps d’arrêt, faisant d’elle la solution idéale pour des lignes de production à grande vitesse. |

| 2.2 Dynamique et Flexible 🌍 |

Que vous marquiez des composants petits et détaillés ou de grandes pièces, la Machine de Marquage Laser Volante s’adapte à une variété de matériaux et de tailles grâce à sa table de travail ajustable et sa tête laser avancée. |

| 2.3 Marquage Laser Haute Précision 🎯 |

Découvrez une précision laser supérieure. Des numéros de série aux logos détaillés, la Machine de Marquage Laser Volante crée des marques nettes, claires et durables—idéales pour les produits nécessitant une gravure haute définition. |

| 2.4 Marques Durables et Résistantes 🌟 |

Les marques produites par la Machine de Marquage Laser Volante sont résistantes à l’usure, garantissant que vos marquages ne s’estompent pas au fil du temps. Idéale pour les produits soumis à des conditions environnementales difficiles. |

| 2.5 Productivité Accrue 📈 |

Grâce à la Machine de Marquage Laser Volante, vous pouvez augmenter considérablement votre production. Des vitesses de marquage plus rapides signifient plus de produits traités en moins de temps, augmentant ainsi l’efficacité générale et réduisant les coûts d’exploitation. |

3️⃣. Pourquoi Choisir la Machine de Marquage Laser Volante ? 🤔

Dans des industries où la vitesse et la précision sont cruciales, la Machine de Marquage Laser Volante offre le meilleur des deux mondes. Avec sa technologie avancée, elle vous aide à réaliser des marquages parfaits à des vitesses plus élevées, tout en garantissant que votre production se déroule sans heurts.

Déverrouillez l’Efficacité et la Précision avec la Machine de Marquage Laser Volante 🚀

Si vous cherchez une machine de marquage laser rapide et précise, la Machine de Marquage Laser Volante est exactement ce qu’il vous faut. Que vous travailliez dans la fabrication, l’électronique, l’automobile ou même la bijouterie, cette machine est conçue pour gérer une variété de matériaux et offrir des résultats cohérents et de haute qualité.

Mais qu’est-ce qui rend cette machine si unique ? 🤔

Examinons les principaux paramètres et pourquoi ils sont essentiels pour vous :

| Paramètre |

Description |

Pourquoi c’est important |

| Puissance Laser |

20W, 30W, 50W |

Détermine la vitesse et la profondeur du marquage. Plus de puissance permet un traitement plus rapide et le marquage de matériaux plus résistants. |

| Zone de Marquage |

110mm x 110mm, 150mm x 150mm |

Une zone de marquage plus grande permet de marquer plusieurs articles à la fois ou des pièces plus grandes, améliorant ainsi la flexibilité de la production. |

| Vitesse de Marquage |

7000 mm/s |

Des vitesses de marquage plus rapides augmentent la productivité, permettant de produire plus d’unités par heure. |

| Type de Laser |

Laser à Fibre |

Offre une haute précision et peut traiter divers matériaux (métaux, plastiques, céramiques) avec un entretien minimal. |

| Résolution |

0.001mm |

Permet des détails ultra-fins, essentiels pour des marques nettes et claires telles que des numéros de série ou des designs complexes. |

| Système de Refroidissement |

Refroidissement par air |

Empêche la surchauffe lors d’une utilisation prolongée, garantissant des performances constantes sans systèmes de refroidissement supplémentaires. |

| Qualité du Faisceau |

<1.5M² |

Assure précision et clarté, produisant des marques détaillées et de haute qualité. |

| Dimensions |

800mm x 600mm x 1150mm |

La taille compacte permet une intégration facile dans les installations existantes tout en optimisant l’efficacité de l’espace. |

| Poids |

Environ 70kg |

Une machine plus lourde offre de la stabilité pendant l’opération, réduisant les vibrations pour des résultats constants. |

| Tension |

220V ±10% |

L’exigence de tension standard permet une intégration fluide avec la plupart des installations électriques existantes. |

Optimisation SEO : En intégrant des termes clés comme Machine de Marquage Laser Volante, précision, vitesse de marquage, et marquage laser à fibre, le texte respecte les bonnes pratiques pour le SEO. Le format structuré, avec des sections claires et des informations pertinentes, garantit également une meilleure lisibilité pour les moteurs de recherche.

Ce texte combine l’approche technique détaillée et le style engageant, tout en assurant une expérience utilisateur fluide et informative. Si vous avez d’autres demandes ou des ajustements à faire, je suis à votre disposition !

Les Avantages de la Machine de Marquage Laser Volante 🚀

Si vous cherchez à augmenter l’efficacité et la précision de votre processus de fabrication, la Machine de Marquage Laser Volante pourrait bien être le changement de jeu dont vous avez besoin. Voici pourquoi vous devriez la considérer :

| # |

Avantage |

Description |

Exemple de Cas |

| 1 |

Vitesse Éclair ⚡ |

La Machine de Marquage Laser Volante fonctionne à une vitesse maximale, assurant un marquage continu en temps réel, gardant votre ligne de production en mouvement sans délai. |

Un grand fabricant automobile a utilisé la machine pour marquer les numéros VIN sur des pièces automobiles pendant qu’elles circulaient sur la chaîne de production, respectant des délais serrés sans compromettre la qualité. |

| 2 |

Précision Inégalée 🎯 |

Offre une précision de pointe, garantissant des marques nettes, propres et cohérentes. Idéale pour une variété de matériaux comme les métaux, les plastiques et plus encore. |

Un fabricant de bijoux a gravé des logos détaillés sur des bagues et bracelets, maintenant l’artisanat sans compromettre la surface de la pièce. |

| 3 |

Sans Contact, Sans Problème 🚫 |

Le processus de marquage sans contact élimine les risques de dommages aux surfaces délicates, obtenant des résultats durables sans toucher physiquement le matériau. |

Une entreprise d’électronique a marqué les numéros de série sur des cartes de circuits délicates sans risquer d’endommager les composants sensibles. |

| 4 |

Entretien Minime, Efficacité Maximale ⚙️ |

Nécessite un entretien minimal, sans encres ni consommables chimiques, offrant plus de temps de fonctionnement et moins de réparations. |

Un fabricant de dispositifs médicaux a constaté une diminution des coûts d’entretien et une augmentation de l’efficacité de la production en utilisant la machine pour des composants de haute précision. |

| 5 |

Intégration Parfaite avec l’Automatisation 🔄 |

S’intègre parfaitement aux lignes de production automatisées, réduisant l’intervention manuelle et garantissant un fonctionnement fluide. |

Une entreprise d’emballage a intégré la machine dans sa ligne automatisée pour marquer les dates de péremption sur les produits alimentaires, augmentant la productivité sans interrompre le processus d’emballage. |

| 6 |

Écologique 🌍 |

Fonctionne proprement sans laisser de déchets, offrant une solution respectueuse de l’environnement pour les entreprises souhaitant réduire leur empreinte écologique. |

Une marque de mode durable a utilisé la machine pour graver des designs personnalisés sur des vêtements écologiques, éliminant les teintures chimiques tout en augmentant l’attrait des produits. |

Applications de la Machine de Marquage Laser Volante 🚀

La polyvalence de la Machine de Marquage Laser Volante en fait une solution très demandée dans divers secteurs. Que vous travailliez avec des matériaux complexes ou ayez besoin de marquages rapides et de haute qualité, cette technologie peut améliorer considérablement l’efficacité de la production et la qualité des produits. Voici quelques applications clés :

| Numéro de Série |

Industrie |

Application Clé |

Pourquoi Ça Fonctionne |

Exemple de Cas |

| 1 |

Industrie Automobile 🚗 |

Marquage des numéros d’identification des véhicules (VIN), numéros de pièces et logos. |

Les pièces automobiles doivent être marquées rapidement et précisément pour répondre aux exigences réglementaires. Le système de marquage laser volant permet un marquage continu sur des pièces mobiles telles que les blocs moteurs, les pneus et les composants électriques sans interrompre le processus de fabrication. |

Un grand constructeur automobile a utilisé le système pour marquer les numéros VIN sur diverses pièces pendant l’assemblage. La technologie laser volante a assuré des marquages clairs, précis et durables, même dans des environnements de production à grande vitesse. |

| 2 |

Industrie de l’Électronique et des Semi-conducteurs 💻 |

Marquage des numéros de série, codes QR et logos de produits sur les cartes de circuits imprimés, puces et autres composants délicats. |

La précision du laser volant permet de marquer même les plus petites pièces sans endommager les matériaux. Idéale pour marquer des matériaux comme les PCB (cartes de circuits imprimés), sensibles à la pression mécanique. |

Une entreprise de semi-conducteurs a utilisé la machine de marquage laser volante pour graver des codes de lot sur des micro-puces. Le processus sans contact a assuré que les puces n’étaient pas endommagées tout en maintenant des marques claires et lisibles répondant aux normes de contrôle qualité. |

| 3 |

Dispositifs Médicaux 🏥 |

Marquage des numéros de série, codes-barres et symboles réglementaires sur les instruments chirurgicaux, implants et autres équipements médicaux. |

Dans le secteur médical, la traçabilité et la stérilisation sont essentielles. La machine de marquage laser volante offre des marques propres, durables et inviolables, nécessaires pour se conformer aux réglementations. |

Un fabricant d’instruments chirurgicaux a adopté le système de marquage laser volant pour graver les numéros de série sur des outils en acier inoxydable. Cela a permis de tracer chaque outil tout au long de son cycle de vie sans compromettre son intégrité. |

| 4 |

Industrie de l’Emballage et de l’Alimentaire 🍽️ |

Marquage des dates de péremption, numéros de lots et autres informations sur les matériaux d’emballage, les bouteilles et les contenants. |

Le système de marquage laser volant permet un marquage continu et rapide sur les matériaux d’emballage, garantissant que les produits soient étiquetés avec précision et prêts à être vendus. Il fonctionne sur une variété de matériaux, y compris le verre, le plastique et le carton. |

Une entreprise d’emballage alimentaire a utilisé la machine de marquage laser volante pour imprimer des dates de péremption sur des contenants à grande vitesse. La précision et la rapidité du système ont assuré qu’il n’y ait pas de perturbations dans la chaîne de production à volume élevé. |

| 5 |

Bijoux et Produits de Luxe 💍 |

Gravure de logos, numéros de série et motifs complexes sur des bagues, montres et accessoires. |

Le marquage laser offre la précision nécessaire pour graver des détails fins sur des articles délicats comme les bijoux. Ce processus sans contact garantit que les pièces restent intactes tout en conservant un niveau élevé de détail. |

Une marque de bijoux de luxe a utilisé la machine de marquage laser volante pour graver des codes uniques et des logos sur leurs pièces. Le résultat a été des marques permanentes, de haute qualité et esthétiquement attrayantes, aidant la marque à lutter contre la contrefaçon. |

| 6 |

Industrie Aérospatiale ✈️ |

Marquage des numéros de série, numéros de pièces et données de sécurité critiques sur les pièces métalliques et composites. |

Les composants aérospatiaux nécessitent souvent des marquages précis et durables pour l’identification et la conformité aux normes de sécurité. La machine de marquage laser volante garantit que les marques peuvent résister à des conditions difficiles telles que la chaleur, l’humidité et les vibrations. |

Un fournisseur de composants aérospatiaux a utilisé la machine de marquage laser volante pour graver des codes de lot et des numéros de pièces sur des composants en titane. Le laser a assuré que chaque pièce puisse être tracée lors des inspections de sécurité et des réglementations strictes. |

| 7 |

Électronique Grand Public 📱 |

Marquage des logos, numéros de série et informations sur les produits électroniques et leurs accessoires. |

La machine de marquage laser volante peut fonctionner à grande vitesse, ce qui la rend idéale pour marquer des surfaces plastiques ou métalliques sur des produits tels que des smartphones, des ordinateurs portables et des écouteurs. |

Un fabricant d’électronique grand public a utilisé le système de marquage laser volant pour graver des numéros de série sur des smartphones. Cela a permis de suivre facilement chaque appareil pendant sa fabrication et de prévenir la contrefaçon des produits. |

| 8 |

Industrie des Outils et du Matériel 🛠️ |

Marquage des logos, numéros de modèles et informations de lot sur les outils, équipements et produits de matériel. |

Les outils et produits de matériel nécessitent des marques claires et durables pour l’identification et pour fournir des données essentielles aux utilisateurs. La machine de marquage laser volante fournit ces marques sans affecter la finition de la surface ni la fonctionnalité. |

Un fabricant d’outils électriques a utilisé la machine de marquage laser volante pour graver des numéros de modèle et des instructions de sécurité sur des composants métalliques. Le résultat a été des marques claires et permanentes qui sont restées intactes même après une utilisation prolongée. |

Résumé : Les machines de marquage laser volantes sont incroyablement polyvalentes et peuvent être appliquées dans une large gamme d’industries. Que vous soyez dans l’automobile, l’électronique, les dispositifs médicaux ou les produits de luxe, cette technologie vous aide à réaliser des marquages rapides et précis qui améliorent la traçabilité, la conformité et l’identité de la marque. C’est la solution idéale pour un marquage continu, sans contact et respectueux de l’environnement. 🌿

Machine de marquage laser traditionnelle vs Machine de marquage laser volante ✨

Lorsqu’il s’agit de technologie de marquage laser, deux des options les plus populaires sont la Machine de Marquage Laser Traditionnelle et la Machine de Marquage Laser Volante. Les deux présentent des avantages, mais elles sont destinées à des besoins de production différents. Analysons leurs principales différences et comprenons dans quel cas chacune est le meilleur choix.

| Critères |

Machine de Marquage Laser Traditionnelle |

Machine de Marquage Laser Volante |

| Vitesse & Efficacité |

Fonctionnement plus lent avec placement manuel des pièces. Rendement plus faible. |

Marquage plus rapide et continu sur des pièces en mouvement. Rendement plus élevé. |

| Précision & Exactitude |

Haute précision, mais affectée par le placement manuel des pièces. |

Précision constante même lors d’opérations continues et à grande vitesse. |

| Compatibilité des matériaux |

Compatible avec divers matériaux (métaux, plastiques, céramiques). |

Fonctionne avec une large gamme de matériaux (métaux, plastiques, verre). |

| Automatisation & Intégration |

Positionnement manuel des pièces. Installation semi-automatisée. |

Entièrement automatisée, s’intègre parfaitement aux lignes de production. |

| Maintenance & Temps d’arrêt |

Nécessite plus de maintenance et d’interventions manuelles. Temps d’arrêt entre les marquages. |

Moins de maintenance avec un marquage continu et moins de temps d’arrêt. |

| Espace & Flexibilité |

Nécessite un espace dédié pour les opérations manuelles. |

Conception compacte, s’intègre facilement dans les lignes de production existantes. |

| Considérations de coût |

Coût initial plus bas, mais coûts d’exploitation potentiellement plus élevés en raison de vitesses plus lentes. |

Coût initial plus élevé, mais rentable pour les opérations à volume élevé. |

| Impact environnemental |

Peut utiliser davantage de consommables (encres/produits chimiques) selon le processus. |

Écologique, sans consommables, processus plus propre. |

1. Vitesse & Efficacité ⚡

Machine de Marquage Laser Traditionnelle : Une machine de marquage laser traditionnelle fonctionne en position fixe, marquant chaque pièce individuellement lorsqu’elle est placée sous le laser. Cela peut être plus lent, surtout dans les environnements de production à volume élevé, car chaque pièce doit être placée manuellement et marquée.

Machine de Marquage Laser Volante : En revanche, la machine de marquage laser volante fonctionne en continu sur des pièces en mouvement, généralement intégrée aux lignes de production automatisées. Elle marque les composants en temps réel à mesure qu’ils se déplacent sur un convoyeur, permettant un marquage beaucoup plus rapide et plus efficace, surtout dans des environnements de production à grande vitesse.

Gagnant : Machine de Marquage Laser Volante (pour des opérations continues et à volume élevé).

2. Précision & Exactitude 🎯

Machine de Marquage Laser Traditionnelle : Les machines traditionnelles offrent une excellente précision et peuvent marquer des conceptions complexes sur une variété de matériaux. Cependant, la précision peut être affectée par le placement manuel des pièces et le processus d’installation.

Machine de Marquage Laser Volante : Le système de marquage laser volante est conçu pour un marquage continu, garantissant que chaque pièce est marquée avec une précision constante. Ces machines sont particulièrement efficaces pour marquer des détails très petits ou complexes sans perdre de précision pendant que la pièce se déplace le long du convoyeur.

Gagnant : Les deux offrent une haute précision, mais la Machine de Marquage Laser Volante excelle dans les opérations continues et à grande vitesse sans sacrifier les détails.

3. Compatibilité des matériaux 🛠️

Machine de Marquage Laser Traditionnelle : Les systèmes traditionnels sont polyvalents et fonctionnent bien avec une large gamme de matériaux, y compris les métaux, les plastiques, les céramiques, etc. Cependant, des ajustements peuvent être nécessaires pour différents matériaux en fonction de la configuration spécifique.

Machine de Marquage Laser Volante : La machine de marquage laser volante est également très adaptable et fonctionne efficacement avec divers matériaux, y compris les métaux, les plastiques et le verre. Elle est souvent utilisée dans des environnements nécessitant un marquage d’articles en mouvement, comme l’industrie automobile ou l’emballage.

Gagnant : Égalité. Les deux sont polyvalentes, mais la machine de marquage laser volante offre plus de flexibilité dans les environnements à grande vitesse.

4. Automatisation & Intégration 🔄

Machine de Marquage Laser Traditionnelle : Les systèmes traditionnels nécessitent souvent une intervention manuelle, surtout pour le positionnement des pièces et l’installation. Bien qu’ils puissent être intégrés dans des systèmes semi-automatisés, ils ne s’adaptent pas aussi facilement aux lignes de production entièrement automatisées.

Machine de Marquage Laser Volante : Un avantage clé des machines de marquage laser volantes est leur capacité à s’intégrer parfaitement aux lignes de production automatisées. Cela permet un marquage automatique pendant que les pièces se déplacent sur des convoyeurs ou à travers des bras robotiques, minimisant l’intervention manuelle et augmentant l’efficacité globale.

Gagnant : Machine de Marquage Laser Volante (idéal pour les lignes de production automatisées à volume élevé).

5. Maintenance & Temps d’arrêt ⚙️

Machine de Marquage Laser Traditionnelle : Les machines traditionnelles ont souvent plus de pièces mobiles nécessitant une maintenance régulière, surtout si le positionnement des pièces est manuel. Le temps d’arrêt entre les opérations de marquage peut également augmenter, affectant l’efficacité globale.

Machine de Marquage Laser Volante : Les systèmes de marquage laser volante ont tendance à avoir moins de pièces mobiles et nécessitent moins de maintenance en raison de leur conception simplifiée. La nature continue de l’opération minimise également les temps d’arrêt, permettant de maintenir les lignes de production en fonctionnement fluide.

Gagnant : Machine de Marquage Laser Volante (pour une maintenance réduite et une opération continue).

6. Espace & Flexibilité 🏠

Machine de Marquage Laser Traditionnelle : Les machines traditionnelles sont généralement plus grandes et peuvent nécessiter un espace dédié pour que l’opérateur place les pièces et gère le système. Le système peut parfois être limité par les contraintes physiques de l’environnement de production.

Machine de Marquage Laser Volante : Les machines de marquage laser volantes sont conçues pour être plus compactes et s’intègrent facilement aux lignes de production automatisées. Étant donné qu’elles marquent des pièces en mouvement, elles économisent de l’espace et peuvent être intégrées dans le flux de production sans nécessiter d’espace supplémentaire pour la gestion manuelle.

Gagnant : Machine de Marquage Laser Volante (plus compacte et adaptable aux environnements automatisés).

7. Considérations de coût 💰

Machine de Marquage Laser Traditionnelle : Les machines de marquage laser traditionnelles sont généralement moins chères à l’achat, car elles ont une conception plus simple et nécessitent moins d’intégration. Cependant, les coûts d’exploitation peuvent être plus élevés dans des environnements à volume élevé en raison des vitesses plus lentes et de la gestion manuelle.

Machine de Marquage Laser Volante : Les machines de marquage laser volantes nécessitent généralement un investissement initial plus élevé, car elles sont conçues pour des environnements automatisés à grande vitesse. Cependant, le retour sur investissement peut être considérable grâce à la productivité accrue, aux coûts de main-d’œuvre réduits et à moins de temps d’arrêt dans les lignes de production à volume élevé.

Gagnant : Machine de Marquage Laser Traditionnelle (pour un coût initial plus bas), mais la Machine de Marquage Laser Volante peut être plus rentable dans les opérations automatisées à volume élevé.

8. Impact environnemental 🌱

Machine de Marquage Laser Traditionnelle : Les systèmes traditionnels utilisent souvent plus de consommables, tels que des encres ou des produits chimiques, selon le processus de marquage. Cela peut entraîner plus de déchets et un impact environnemental plus élevé.

Machine de Marquage Laser Volante : Le marquage laser volant est une option plus écologique car il ne nécessite pas de consommables, ce qui n’entraîne aucun déchet d’encre ou de produit chimique. La nature sans contact du processus le rend également plus propre.

Gagnant : Machine de Marquage Laser Volante (plus écologique, sans consommables).

Résumé :

Les Machines de Marquage Laser Traditionnelles sont idéales pour des opérations à faible volume, offrant une précision fiable et une grande polyvalence à un coût inférieur. Elles sont parfaites lorsque le placement manuel des pièces et un marquage plus lent mais plus précis sont acceptables.

En revanche, les Machines de Marquage Laser Volantes excellent dans des environnements de production à haute vitesse et à volume élevé où l’automatisation est une priorité. Elles sont plus rapides, plus efficaces et s’intègrent parfaitement aux lignes automatisées, ce qui en fait le meilleur choix pour des industries comme l’automobile, l’électronique, l’emballage, et plus encore.

En conclusion, si vous travaillez avec un haut débit et avez besoin d’un marquage continu et précis avec une intervention manuelle minimale, la Machine de Marquage Laser Volante est le choix évident. Pour des projets plus petits et personnalisés, la Machine de Marquage Laser Traditionnelle pourrait être une meilleure option.

AQ – Foire Aux Questions

1️⃣ Qu’est-ce qu’une Machine de Marquage Laser Volant en Ligne ?

Une Machine de Marquage Laser Volant en Ligne est un système de marquage laser spécialisé, conçu pour marquer en continu et à grande vitesse des produits qui se déplacent le long d’une chaîne de production. Contrairement aux machines laser traditionnelles stationnaires, ce système utilise une optique volante qui marque les articles pendant leur déplacement, ce qui le rend idéal pour les processus de fabrication à grand volume dans des secteurs comme l’emballage, l’automobile, l’électronique, et l’agroalimentaire.

2️⃣ Comment fonctionne la Machine de Marquage Laser Volant en Ligne ?

Cette machine utilise un faisceau laser dirigé par des optiques volantes qui se déplacent en synchronisation avec le convoyeur ou la ligne de production. Lorsque les produits passent dans la zone de marquage, le laser les marque en temps réel. La synchronisation du système avec la ligne de production assure que chaque produit est marqué avec précision, qu’il s’agisse de codes-barres, de QR codes, de numéros de série ou de logos, sans ralentir la vitesse de production.

3️⃣ Quels secteurs bénéficient de l’utilisation de la Machine de Marquage Laser Volant en Ligne ?

La Machine de Marquage Laser Volant en Ligne est parfaite pour les secteurs où les produits doivent être marqués rapidement et de manière constante en se déplaçant le long d’une ligne de production, tels que :

-

Emballage (marquage de logos, numéros de lots, dates de péremption)

-

Automobile (marquage de pièces ou numéros de série)

-

Électronique (gravure de codes-barres, numéros de modèles, logos)

-

Agroalimentaire (marquage des emballages avec les dates de production ou de péremption)

-

Pharmaceutique (marquage des flacons de médicaments avec des codes-barres et des identifiants)

4️⃣ Quels matériaux peuvent être marqués avec la Machine de Marquage Laser Volant en Ligne ?

Cette machine peut marquer une grande variété de matériaux, notamment :

Elle est idéale pour de nombreux processus de fabrication nécessitant un marquage précis et rapide.

5️⃣ Qu’est-ce qui distingue la Machine de Marquage Laser Volant en Ligne des systèmes de marquage laser traditionnels ?

La principale différence réside dans le fait que la Machine de Marquage Laser Volant en Ligne est conçue pour fonctionner sur des produits en mouvement, alors que les systèmes laser traditionnels nécessitent que les produits soient stationnaires pendant le marquage. Cette machine est idéale pour les environnements à fort débit, où la vitesse et l’efficacité de la production sont essentielles. Elle s’intègre également facilement aux systèmes automatisés pour une opération fluide.

6️⃣ Quels sont les avantages de la Machine de Marquage Laser Volant en Ligne ?

-

Marquage à grande vitesse sur les produits en mouvement, s’adaptant aux lignes de production rapides.

-

Marquage sans contact, garantissant que le produit ne soit pas endommagé pendant le processus.

-

Haute précision et constance, même sur des formes complexes et des matériaux variés.

-

Entretien minimal et faibles coûts d’exploitation, réduisant les temps d’arrêt et améliorant le retour sur investissement (ROI).

-

Marquages personnalisables, y compris des codes-barres, des QR codes, des numéros de série et des logos.

7️⃣ La Machine de Marquage Laser Volant en Ligne est-elle facile à intégrer dans une ligne de production existante ?

Oui, cette machine est conçue pour être facilement intégrée dans des lignes de production automatisées existantes. Elle peut être synchronisée avec des systèmes de convoyeurs et de contrôle de mouvement pour garantir un minutage et une coordination précis. Le système est généralement fourni avec un logiciel compatible avec les contrôleurs PLC, permettant une opération fluide sans perturber les flux de travail existants.

8️⃣ La Machine de Marquage Laser Volant en Ligne peut-elle gérer une production à grande échelle ?

Absolument ! La Machine de Marquage Laser Volant en Ligne est construite pour un marquage continu à grande vitesse, ce qui la rend idéale pour des environnements de production à fort volume. Elle peut marquer des centaines voire des milliers de produits par heure, garantissant que les processus de fabrication à grande échelle restent efficaces sans compromettre la qualité.

9️⃣ Quel type d’entretien est nécessaire pour la Machine de Marquage Laser Volant en Ligne ?

Bien que la machine nécessite peu d’entretien, il est important de :

-

Nettoyer régulièrement les lentilles et les miroirs pour garantir des performances optimales du laser.

-

Vérifier l’alignement du système pour maintenir un marquage précis.

-

Surveiller le système de refroidissement pour éviter la surchauffe, en particulier lors des applications à grande vitesse.

-

Vérifier que la courroie du convoyeur ou d’autres pièces mobiles fonctionnent correctement.

🔟 Quelle est la durée de vie d’une Machine de Marquage Laser Volant en Ligne ?

La Machine de Marquage Laser Volant en Ligne est conçue pour durer longtemps lorsqu’elle est correctement entretenue. La source laser à fibre dure généralement entre 20 000 et 30 000 heures d’exploitation continue, selon le modèle et les conditions d’utilisation. Cela en fait une solution rentable pour les environnements de fabrication à fort volume sur le long terme.

1️⃣1️⃣ Est-ce difficile de programmer la Machine de Marquage Laser Volant en Ligne ?

Pas du tout ! La machine est généralement livrée avec un logiciel facile à utiliser, permettant de programmer des conceptions et du texte personnalisés. Vous pouvez importer directement des fichiers CAD, des logos ou d’autres fichiers image dans le système. Le logiciel fournit des outils simples pour ajuster la taille, l’orientation et le placement du texte, ce qui permet de l’adapter facilement à vos besoins de production.

1️⃣2️⃣ Quels types de marques la Machine de Marquage Laser Volant en Ligne peut-elle créer ?

La Machine de Marquage Laser Volant en Ligne peut produire une variété de marques, y compris :

Ces marques sont permanentes, très lisibles et résistantes à l’usure et aux facteurs environnementaux, ce qui les rend idéales pour les produits nécessitant une traçabilité et une identification.

1️⃣3️⃣ La Machine de Marquage Laser Volant en Ligne peut-elle être utilisée pour graver et découper ?

Cette machine est principalement conçue pour le marquage et la gravure. Cependant, certains modèles plus puissants peuvent également réaliser des découpes légères de matériaux plus tendres, tels que les plastiques et les métaux fins. Elle n’est pas généralement utilisée pour des découpes profondes, mais elle peut effectuer efficacement des gravures et des marquages en surface.

1️⃣4️⃣ Quelles options de puissance sont disponibles pour la Machine de Marquage Laser Volant en Ligne ?

La Machine de Marquage Laser Volant en Ligne est disponible avec plusieurs options de puissance, allant de lasers de 20W à 100W, en fonction de l’application et du matériau à traiter. Les modèles plus puissants sont adaptés pour marquer les métaux et les matériaux plus durs, tandis que les modèles moins puissants conviennent mieux aux plastiques et aux étiquettes.