1.The birth of 3D laser marking machine

In the traditional plane marking machine, the workpiece must be placed on the same plane, and the processing surface must also be on the same plane, in order to achieve one-time marking, and cannot complete the surface marking.

With the increasing demand for individualization and customization in the manufacturing industry, the 3D laser marking machine came into being. The surface shape of the processed object is no longer limited to a plane-like surface, and can be extended to a three-dimensional surface to achieve high-efficiency laser graphic marking and surface microstructure manufacturing of three-dimensional curved objects. 3D printing once attracted much attention because it can realize the integrated molding of various shapes.

2.The principle of 3D laser marking machine

Second, the principle of 3D laser marking machine

A high-energy density laser is used to locally irradiate the workpiece to vaporize the surface material or undergo a chemical reaction of color change, thereby leaving a permanent mark.

Laser marking can mark a variety of characters, symbols and patterns, etc., and the size of the characters can even reach the order of microns.

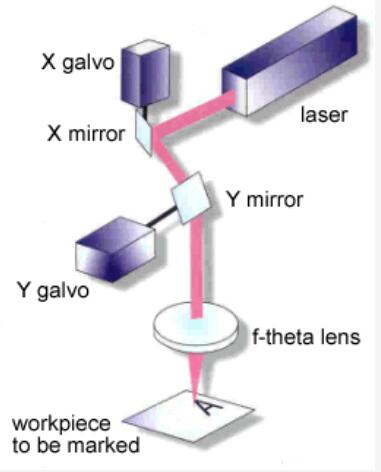

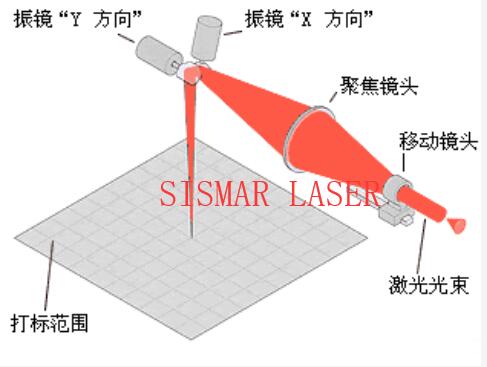

The laser beam used for laser marking is generated by a laser. After a series of optical transmission and processing, the beam is finally focused by an optical lens, and then the focused high-energy beam is deflected to the specified position on the surface of the object to be processed, forming a permanent depression trace.

Traditional 2D laser marking uses a rear focus method, and generally can only perform flat marking within a specified range.

The advent of the new 3D laser marking machine has solved the long-standing inherent defect of the 2D laser marking machine. The 3D laser marking machine adopts an advanced front gathering method and has more dynamic focus seats. This adopts optical principles, similar to The working principle of candle imaging is to control and move the dynamic focus lens through software, and perform variable beam expansion before the laser is focused, so as to change the focal length of the laser beam to achieve accurate surface focusing processing on objects of different heights.

3.3D laser marking machine structure

The 3D laser marking machine has high photoelectric conversion rate, long service life, easy maintenance, and fast marking speed, which greatly improves the processing efficiency. High-precision three-dimensional positioning technology, high-speed focusing on the scanning system, laser beam fundamental mode, short pulse, high peak power, high repetition rate, bring perfect marking effect to customers.

4.3D laser marking application

1). Large-scale marking

3D marking can be divided into two types: front focus and back focus. When the front focus mode is used, the main purpose is to achieve a larger marking range. Generally, a larger X, Y axis deflection lens is used to allow the incident laser spot to be more Larger, a smaller focused spot is obtained, and the energy density is higher; thereby meeting the requirements of a larger area.

As long as the shape of the workpiece is set in advance, only switching settings can correspond to the focal length, marking position and shape changes of different product positions. It can be completed without moving the workpiece multiple times or laser marking.

2). Deep engraving

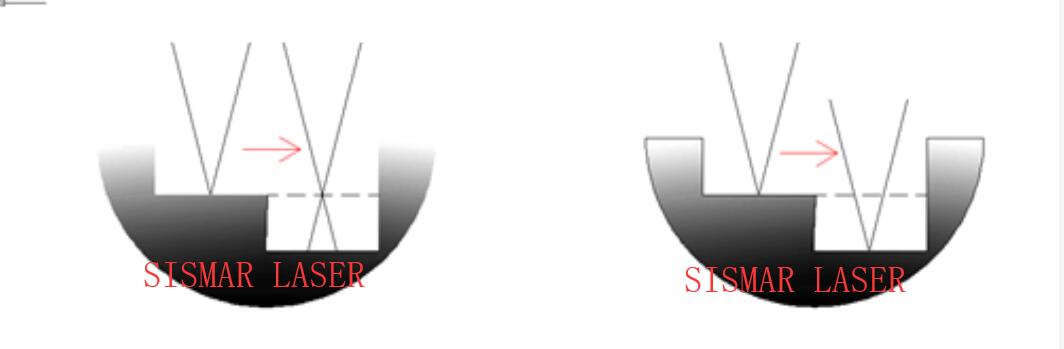

Traditional 2D marking has inherent defects in deep engraving of the object surface. As the laser focus moves up during the engraving process, the laser energy acting on the actual surface of the object will drop sharply, which seriously affects the effect and efficiency of deep engraving.

3D marking for deep engraving processing does not have the above problems, which not only ensures the effect, but also improves the efficiency. The 3D laser marking machine enhances the technical application range for laser marking processing and expands the demand for surface marking.

As the laser scribing progresses, the processed surface gradually moves away from the focus, entering a state where energy cannot be completely transferred. Automatically adjust the focus while scoring. The processed surface is always marked with the highest density energy.

3). High and low surface marking

Since 3D marking can quickly change the laser focal length and laser beam position, it becomes possible to mark curved surfaces that were not possible in 2D in the past. After using 3D marking, the cylindrical marking in the light projection range can be completed at one time, which greatly improves the processing efficiency.

Furthermore, the surface shape of many parts of industrial products is not just a flat surface. It is really powerless for 2D marking processing. At this time, 3D marking is easier to achieve, achieving accurate focus at any time and ensuring sharpness and uniformity. The engraving effect. There is no need to worry about poor marking caused by focus shift, so there is no need to set a strong laser output beyond the normal range. It not only ensures stable marking quality, but also helps reduce the load on the device and realize energy-saving operation.

5.Application areas

It is suitable for the laser marking of various metal or non-metal products with three-dimensional curved surfaces, and is widely used in the laser three-dimensional marking of products in the industries of mobile phone manufacturing, three-dimensional circuits, medical equipment, molds, 3C electronics, auto parts, and electronic communications.