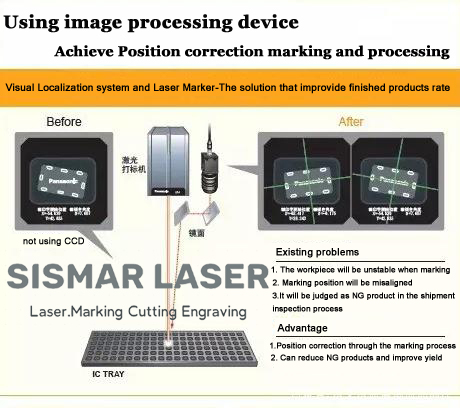

CCD Camera Laser Marking Machine With Visual Localization System

Traditional Laser Marking Machine Industry description

During the marking process, the processed parts must be in a fixed position and must not be shaken during the process.

The processed patterns can be processed to the designated position of the product. These are our common knowledge of the processing technology of traditional laser marking machines.

In the process of product marking, traditional laser marking machines need to customize simple or complex jigs for positioning, and will encounter the following problems.

1. Using precision jigs: New products require new precision jigs, which increases the cost and extends the production cycle.

2. Using simple jigs: the marking efficiency of manual operation is low, and if it is a little careless, it will be biased, affecting the aesthetics of the product.

When the traditional laser marking machine needs to realize automatic production, it has high requirements on mechanical accuracy. Making a complex automation supporting line can only be applied to one or a few products. For new products, it is necessary to make new production lines, which is not only long-term but also very unfavorable to the cost management of the factory.

During the marking process, the processed parts must be in a fixed position and must not be shaken during the process.

The processed patterns can be processed to the designated position of the product. These are our common knowledge of the processing technology of traditional laser marking machines.

In the process of product marking, traditional laser marking machines need to customize simple or complex jigs for positioning, and will encounter the following problems.

1. Using precision jigs: New products require new precision jigs, which increases the cost and extends the production cycle.

2. Using simple jigs: the marking efficiency of manual operation is low, and if it is a little careless, it will be biased, affecting the aesthetics of the product.

When the traditional laser marking machine needs to realize automatic production, it has high requirements on mechanical accuracy. Making a complex automation supporting line can only be applied to one or a few products. For new products, it is necessary to make new production lines, which is not only long-term but also very unfavorable to the cost management of the factory.

Principle of CCD vision Laser marking machine:

Based on the foundation of the traditional Laser marking machine, a high-precision CCD camera is used to capture the current position of the product, and the position information of one or more products collected in real time is sequentially transmitted to the marking card through the computer to achieve accurate marking .

The core function of the CCD visual positioning laser marking machine is the CCD visual positioning function, which can automatically identify product features for laser marking to achieve rapid positioning, and even small objects can also be marked with high precision, without the need to use fixtures, reducing With manual participation, work efficiency is improved.

The use of CCD visual positioning laser marking machine will not cause missed or broken light. It can mark multiple products at one time, and it can also be automatically loaded on the assembly line. After rough positioning, visual positioning marking is performed, which saves labor and It can improve production efficiency, easily realize an automatic production line compatible with multiple products, and save a lot of costs for the factory.

The CCD vision laser marking machine uses the principle of visual positioning.

First develop the template of the product, determine the shape of the product, save it as a standard template, take pictures of the product to be processed during normal processing, and compare and position the template by the computer to quickly compare the template machining.

The CCD vision laser marking machine uses the principle of visual positioning.

First develop the template of the product, determine the shape of the product, save it as a standard template, take pictures of the product to be processed during normal processing, and compare and position the template by the computer to quickly compare the template machining.

The shape of the processed product can be round, square or irregular.

This process is particularly suitable for small products, which can eliminate the processing of positioning trays and fixed fixtures.

Greatly save the laser marking processing cycle.

Since then, the small size products no longer become the pain that laser marking dare not touch.

With the addition of CCD visual positioning, “small” becomes “large”, and the accuracy problems that traditional marking machines cannot control are solved here.