150W 200W Benchtop Jewelry Laser Welding Machine

/0 Comments/in Products /by linda

BenchTop Jewelry Laser Welding Machine

Introducing our Benchtop Jewelry Laser Welding Machine – the perfect solution for jewelers looking for a space-saving yet powerful tool. This compact machine combines high precision and efficiency, making it ideal for jewelry repair and design in limited spaces without compromising performance.

Key Features:

- Space-Saving Design: Compact size fits perfectly in small workshops, allowing you to maximize workspace while still benefiting from powerful capabilities.

- Precision Welding: Perfect for delicate tasks such as prong, setting, and chain repairs, ensuring clean, accurate welds without damaging surrounding materials.

- Versatile Applications: Ideal for a range of metals including gold, silver, platinum, and titanium, making it perfect for resizing rings, repairing prongs, fixing chains, and addressing porosity issues.

- User-Friendly: Easy to operate, making it suitable for jewelers of all experience levels.

Perfect for small workshops, retail stores, or any space where efficiency and quality are paramount, this machine is designed to enhance your business while saving precious workspace.

BenchTop Jewelry Laser Welding Machine

Introducing the Benchtop Jewelry Laser Welding Machine — the ultimate solution for jewelers looking to elevate their craft. Whether you’re working in a compact space or need something to handle higher demands, this jewelry laser welding machine offers three power options: 100W, 150W, and 200W. No matter the power level you choose, you’ll get precise, reliable welding that suits your needs.

Power Options for Every Need:

100W Model: Perfect for light to medium jewelry repairs, this jewelry laser welding machine works wonders on smaller tasks like resizing rings, repairing prongs, or fixing delicate chains. However, to keep things running smoothly, it’s best to use this model in a well-ventilated room, preferably with air conditioning. It’s not recommended for extended use without proper cooling, as it can overheat, limiting performance.

150W Model: The 150W version strikes a perfect balance — small in size, but big on power. Ideal for jewelers who have limited space but still need reliable performance, this option delivers the precision you need for standard jewelry repairs. It’s a great upgrade from the 100W, offering more power without taking up much more space.

200W Model: Need extra power for bigger, more intricate jobs? The 200W jewelry laser welding machine is your go-to tool. It’s built for high-demand tasks, making quick work of larger repairs or thick metals. If your jewelry shop is bustling with activity and you need something that can handle speed and precision, this is the model for you.

Benchtop Jewelry Laser Welding Machine Specifications

Looking for a powerful, space-saving solution for your jewelry repair and design needs? Our Benchtop Jewelry Laser Welding Machine is available in three models—100W, 150W, and 200W—giving you the flexibility to choose the right machine for your workspace and workload.

| Feature | 100W Model | 150W Model | 200W Model |

|---|---|---|---|

| Laser Type | Nd:YAG 1064 nm | Nd:YAG 1064 nm | Nd:YAG 1064 nm |

| Average Power | 100W | 150W | 200W |

| Peak Power | 3.5 kW | 7.2 kW | 8 kW |

| Energy Range | 0.1 – 80 J | 0.1 – 180 J | 0.1 – 200 J |

| Pulse Duration | 0.1 – 25 milliseconds | 0.1 – 25 milliseconds | 0.1 – 25 milliseconds |

| Welding Frequency | 1 – 30 Hz | 1 – 30 Hz | 1 – 30 Hz |

| Spot Diameter | 0.2 – 2.0 mm | 0.2 – 2.0 mm | 0.2 – 2.0 mm |

| Input Power | 110 or 230 V AC, 50/60 Hz, Single Phase | 110 or 230 V AC, 50/60 Hz, Single Phase | 110 or 230 V AC, 50/60 Hz, Single Phase |

| Dimensions (L×W×H) | 76 × 53 × 56 cm | 76 × 53 × 56 cm | 76 × 53 × 56 cm |

| Weight | ~43 kg | ~43 kg | ~43 kg |

Why Choose Our Benchtop Jewelry Laser Welding Machine?

When you need precision and performance in a compact design, this machine checks all the boxes. Whether you’re running a small workshop or tackling high-demand jobs, here’s what you can expect:

- Compact Yet Powerful: Say goodbye to bulky equipment. These machines offer robust performance without taking up your precious workspace.

- Perfect for Jewelry Repairs: Whether you’re resizing rings, fixing chains, or welding prongs, this machine does it all with laser accuracy.

- User-Friendly: Don’t be intimidated—our easy-to-use interface lets you weld with precision, no matter your skill level.

Which Model Is Right for You?

100W Model: If you’re handling light to medium jewelry repairs and have access to an air-conditioned room for cooling, this is a great choice. It’s perfect for jewelers in smaller, more controlled environments.

150W Model: This one strikes the perfect balance between power and size. Small enough to fit into tight spaces, yet powerful enough for standard repairs. If you’re ready to take your welding to the next level, this is your go-to option.

200W Model: Need speed and power for demanding projects? The 200W machine delivers quick, strong welds for even the toughest tasks. Ideal for high-volume production spaces or complex repairs.

Applications for the Benchtop Jewelry Laser Welding Machine:

- Ring Resizing: Adjust sizes easily and accurately. Perfect fit, every time.

- Prong Repair: Secure your gemstones with precision welding that strengthens prongs.

- Chain Repair: Fix broken chains with seamless welds that restore their original integrity.

- Porosity Filling: Eliminate casting defects and ensure that every piece is structurally sound.

Invest in the Benchtop Jewelry Laser Welding Machine today and start delivering high-quality repairs and designs with ease, precision, and speed. Whether you’re working in a small space or need a powerhouse for high-demand tasks, we’ve got you covered.

Why Choose Our Benchtop Jewelry Laser Welding Machine?

Space-Saving, High-Power Design: Each model is compact, saving you valuable workspace without sacrificing power. Whether you’re welding gold, silver, or titanium, you’ll get top-notch results every time.

Versatility Across Tasks: From resizing rings and fixing chains to repairing prongs and filling porosity, this machine’s versatility makes it perfect for every type of jewelry repair.

Reliable Cooling and Consistent Performance: The 200W model features advanced cooling technology, keeping the machine performing at its peak even during extended use.

No matter which power option you choose, our Benchtop Jewelry Laser Welding Machine ensures that your jewelry repair process is faster, more precise, and space-efficient. Ready to upgrade your shop with the best in jewelry laser welding technology? The choice is simple.

🔧 Why Choose the Benchtop Jewelry Laser Welding Machine?

If you’re looking to level up your jewelry repair and design game, the Benchtop Jewelry Laser Welding Machine could be your secret weapon. It’s not just compact and powerful, it offers several distinct advantages over other types of jewelry laser welding machines. Here’s why this space-saving solution might be the perfect fit for your shop:

1. 🌟 Space-Saving Design – Perfect for Small Spaces

One of the biggest benefits of the Benchtop Jewelry Laser Welding Machine is its small footprint. Unlike larger industrial laser welders, this model doesn’t take up valuable space in your workshop. It’s ideal for jewelers with limited room but who still need precision and power.

💡 Key Benefit: It’s compact enough to fit in tight spaces, making it perfect for small workshops or retail setups.

2. ⚡ Flexible Power Options for Versatile Use

The Benchtop Jewelry Laser Welding Machine comes in three different power configurations: 100W, 150W, and 200W. This range allows you to choose the ideal power level that best suits your needs.

- 100W: Great for light repairs. However, it works best in a controlled, air-conditioned environment.

- 150W: Perfect balance of power and compact design, making it great for standard repairs.

- 200W: Ideal for more demanding tasks and thicker metals. Best for high-performance jobs.

🔑 Tip: Pick the right power to optimize your workflow!

3. 💎 High Precision and Clean Joints

Precision is the core strength of the Benchtop Jewelry Laser Welding Machine. Whether you’re resizing rings, repairing prongs, or fixing delicate chains, expect clean, accurate welds every time.

✔️ Benefits:

- Minimal heat to protect delicate gemstones.

- Focused laser beam ensures perfect bonding without the need for extra filler.

4. 🧑🏫 User-Friendly and Easy to Operate

The Benchtop Jewelry Laser Welding Machine is designed with ease of use in mind. Even beginners can get started quickly, thanks to its intuitive controls. Unlike more complex machines, this model requires no steep learning curve.

5. 🔨 Ideal for Small to Medium Jewelry Jobs

Perfect for custom pieces or delicate repairs, the Benchtop Jewelry Laser Welding Machine is made for small to medium-sized tasks. It’s not for mass production, but precision crafting—ideal for jewelers who specialize in unique or intricate designs.

🔍 Best For:

- Ring resizing

- Prong repairs

- Chain fixes

6. 💰 Affordable and Energy Efficient

Looking for a cost-effective solution? The Benchtop Jewelry Laser Welding Machine offers powerful results without breaking the bank. It’s more energy-efficient than larger models, helping you save on utility costs while delivering high-quality welds.

7. 🔥 Less Heat, Less Risk

Since this machine uses a focused laser beam, there’s significantly less heat than traditional welding methods. This means less risk of warping your metals or damaging gemstones.

💡 Why it matters:

- Stronger, more durable welds.

- No compromise on the integrity of your work.

🌟 Key Takeaways:

The Benchtop Jewelry Laser Welding Machine is a game-changer for jewelers. With its space-saving design, customizable power options, and precision welding, it’s the perfect solution for small to medium-sized jewelry repairs and designs. Whether you’re upgrading your current equipment or just starting, this machine will help you get the job done faster and better.

🔧 Ready to elevate your jewelry business? The Benchtop Jewelry Laser Welding Machine is here to help you create beautiful, intricate jewelry with ease.

💍 Applications of the Benchtop Jewelry Laser Welding Machine

The Benchtop Jewelry Laser Welding Machine is a versatile tool, ideal for a wide range of jewelry repair and design applications. Whether you’re working with gold, silver, platinum, or titanium, this machine’s high precision and efficiency make it perfect for a variety of tasks. Below are some key applications that showcase the power and flexibility of this machine:

1. 🔧 Ring Resizing and Adjustment

The Benchtop Jewelry Laser Welding Machine makes ring resizing a breeze. Whether you’re adding or removing material, you can achieve seamless, strong welds without affecting the ring’s original structure. Perfect for adjusting rings to fit a variety of sizes or creating custom designs.

- Ideal for: Wedding rings, engagement rings, and other custom jewelry.

2. 💎 Prong Repair and Reinforcement

If a gemstone’s prong becomes loose or damaged, the Benchtop Jewelry Laser Welding Machine allows for precise prong repairs. With laser welding, you can strengthen or replace prongs without disturbing the gemstone or surrounding materials, ensuring that the precious stone stays securely in place.

- Ideal for: Setting or resetting gemstones like diamonds, sapphires, or emeralds.

3. 🔗 Chain Repair and Restoration

Broken chains can now be fixed quickly and efficiently with laser welding. The Benchtop Jewelry Laser Welding Machine offers the precision necessary to restore chains to their original form, eliminating the need for traditional soldering. This results in smoother joints with less heat distortion.

- Ideal for: Gold, silver, and delicate chain repairs.

4. 🔨 Porosity Filling and Casting Repairs

Over time, casting defects such as porosity can weaken jewelry. The Benchtop Jewelry Laser Welding Machine offers a quick, reliable solution by filling voids in the metal. This ensures the structural integrity of your jewelry while maintaining its aesthetic quality.

- Ideal for: Jewelry casting repairs and addressing manufacturing defects.

5. 🪄 Fine Detail Welding

For intricate, detailed jewelry pieces, the Benchtop Jewelry Laser Welding Machine provides superior precision for small, complex welds. Whether you’re creating fine designs or repairing delicate components, the focused laser ensures perfect results every time.

- Ideal for: Filigree, engraving, and detailed custom designs.

6. 🔧 Quick Fixes for Everyday Repairs

The Benchtop Jewelry Laser Welding Machine is perfect for jewelers who need to perform quick repairs without sacrificing quality. Whether it’s a broken clasp, loose setting, or minor crack, this machine allows you to repair jewelry efficiently, saving time and resources.

- Ideal for: Quick fixes for everyday jewelry maintenance.

7. 🏆 Custom Jewelry Creation

For jewelers looking to create custom pieces, this machine offers unmatched flexibility. From adding decorative elements to welding unique designs, the Benchtop Jewelry Laser Welding Machine is the perfect tool for bringing your creative vision to life.

- Ideal for: Jewelry designers and custom shops offering bespoke pieces.

💡 In Summary:

The Benchtop Jewelry Laser Welding Machine is a highly versatile tool that meets the needs of jewelers across various applications. From ring resizing and prong repairs to chain restoration and casting repairs, its precision and power make it an essential asset for both repair and custom jewelry creation. Whether you’re working on small-scale repairs or complex designs, this machine helps ensure your jewelry is crafted to perfection.

FAQ – Benchtop Jewelry Laser Welding Machine

1️⃣ What is a Benchtop Jewelry Laser Welding Machine?

A Benchtop Jewelry Laser Welding Machine is a compact, high-precision welding tool designed for delicate jewelry repairs and fabrication. It uses focused laser energy to weld metals together with extreme accuracy, making it ideal for working on small, intricate pieces such as rings, bracelets, and pendants.

2️⃣ How does a Benchtop Jewelry Laser Welding Machine work?

The machine directs a focused laser beam at the joint area of the metals to be welded. The intense heat from the laser melts the metal, allowing it to fuse together. The process is highly controlled, so you can make precise, strong welds without affecting the surrounding areas of the jewelry.

3️⃣ What materials can be welded with this machine?

Benchtop jewelry laser welders are typically used for welding precious metals like gold, silver, platinum, and their alloys. Some models can also handle base metals such as copper and stainless steel, although the settings may need to be adjusted accordingly.

4️⃣ What are the advantages of a Benchtop Jewelry Laser Welding Machine?

- Precision: The laser’s focused energy allows for precise welds, even on intricate jewelry designs.

- Minimal Heat Affected Zone (HAZ): The heat generated by the laser is concentrated only on the weld area, reducing the risk of damage to surrounding material.

- No Need for Filler Material: In many cases, the laser welding process doesn’t require filler material, which preserves the piece’s aesthetics.

- Clean, Smooth Welds: The welding process produces a clean and smooth finish, eliminating the need for additional finishing work.

- Compact Size: Benchtop models are smaller and more versatile, taking up less space than larger machines, making them ideal for smaller workshops or jewelry stores.

5️⃣ Is the Benchtop Jewelry Laser Welding Machine easy to operate?

Yes, most benchtop models are designed with user-friendliness in mind. They typically feature intuitive touchscreen controls, adjustable power settings, and fine-tuning options for different materials. While training may be required to get familiar with the machine, it is usually quick to learn for most users.

6️⃣ Can the machine be used for jewelry repair?

Absolutely. Benchtop jewelry laser welders are commonly used for repairing jewelry, such as resizing rings, reattaching stones, fixing clasps, and even restoring damaged pieces. Their precision allows for repairs without disrupting the overall design of the jewelry.

7️⃣ What safety measures should be followed when using the machine?

- Eye Protection: Always wear laser safety goggles to protect your eyes from the high-intensity light produced by the laser.

- Ventilation: Ensure proper ventilation in the workspace to eliminate any harmful fumes that may be produced during welding.

- Protective Gear: Wear appropriate gloves and clothing to prevent burns or injury from the laser or molten metal.

- Machine Safety Lock: Many machines have a safety lock feature that prevents accidental activation, enhancing overall safety.

8️⃣ How does the Benchtop Jewelry Laser Welding Machine compare to other types of welders?

Benchtop jewelry laser welders are smaller and more precise than larger industrial laser welders, making them ideal for delicate work on jewelry. They also provide more control over the heat output, which helps preserve the fine details of the jewelry. In comparison to traditional welding methods, the laser welding process is cleaner, faster, and more accurate, with minimal distortion of the material.

9️⃣ What is the price range of a Benchtop Jewelry Laser Welding Machine?

The price of a benchtop laser welding machine typically ranges from $3,000 to $15,000 USD, depending on the brand, features, and power capabilities. While the initial cost may seem high, the machine’s precision, speed, and ability to eliminate the need for additional labor or repairs make it a worthwhile investment in the long run.

🔟 How often should the Benchtop Jewelry Laser Welding Machine be maintained?

Regular maintenance is key to keeping the machine in optimal condition:

- Clean the laser lens and mirrors to ensure clear, effective welding.

- Check and maintain the cooling system to prevent overheating.

- Ensure the machine is properly calibrated for accurate welds.

- Regularly inspect the system for any signs of wear or damage, such as worn-out parts or faulty electrical components.

Jewelry Laser Welding Video

Request a Quote for a Jewelry Laser Welding Machine

SISMAR LASER has laser welding machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser welding system or an excellent choice for your first laser machine.

Request a quote for a high-quality jewelry laser welding machine that exceeds your expectations. You can also schedule a demo to see how jewelry laser welding machine works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

Pedestal Jewelry Laser Welding Machine

/0 Comments/in Products /by linda

200W Jewelry Laser Welding Machine

Pedestal Jewelry Laser Welding Machine

200W Jewelry Laser Welding Machine: Precision and Power 💎

The 200W Jewelry Laser Welding Machine offers high precision and powerful performance for gold, platinum, silver, and titanium welding.

🔹 Key Features:

- 200W Laser for deep, fast welds.

- Precision for intricate repairs and stone setting.

- Ideal for jewelry, electronics, and medical devices.

- Ergonomic design for comfortable operation.

- Advanced cooling system for consistent performance.

Perfect for professionals seeking reliable and precise welding results.

Pedetal jewelry Laser Welding Machine Photo

Transform Your Jewelry Repair with the Pedestal Jewelry Laser Welding Machine ✨

Tired of struggling with traditional welding methods that damage your delicate jewelry? The Pedestal Jewelry Laser Welding Machine is here to revolutionize your repair and crafting process. 🔥

💎 Why This Machine is a Game-Changer:

- Precision & Perfection: Get clean, strong, and accurate welds every time, no matter how intricate the design. No more uneven welds or melted edges—just flawless results.

- Effortless Control: Adjustable power settings allow for precise welding on the finest jewelry, giving you full control over the process.

- Pedestal Design for Flexibility: The pedestal design allows for greater flexibility and ease of use, with the jewelry piece positioned at a comfortable height for the operator. Work with ease, no matter the project.

- High-Precision Microscope: A built-in microscope provides a magnified, crystal-clear view of the welding area, ensuring precise control over every detail of your welding process.

- Optional CCD Camera System: For larger parts, the optional CCD camera system gives you a clear view of the entire marking process, ensuring high-quality results every time.

🚀 Key Benefits:

- Speed & Efficiency: Weld quickly and effectively with minimal heat, preserving the integrity of your pieces.

- Durable Welds: Perfect for repairs and attaching small components without sacrificing strength.

- Compact and Professional: A space-saving pedestal design that integrates seamlessly into your workspace.

Ready to take your jewelry craftsmanship to the next level? The Pedestal Jewelry Laser Welding Machine is the tool you need for precision, speed, and flawless results. Get yours today and start creating the masterpieces you’ve always dreamed of! 🌟

| Category | Details |

|---|---|

| System Platform | Pedestal |

| Welding Chamber Safety Certification Class | Class 1 |

| iWeld Lasing System Class | Class 4 |

| Wavelength | 1,064nm |

| Power Supply | 220V±10%, 50Hz/60HZ |

| Laser Source | ND:YAG |

| Pulse Width | 0.1 – 10ms |

| Average Power | 200 Watts |

| Pulse Length | 0.1 – 50 Milliseconds |

| Pulse Frequency | ≤50Hz |

| Burst / Speed Welding | Optimized to Energy Values |

| Beam Diameter | 0.05mm – 2.00mm |

| Cooling System | Internal Water – To – Air |

| Supply Circuit | 220V±10%, 50Hz/60HZ |

| Binocular Microscope | 15x (optional 25x, 40x) |

| Chamber Illumination System | LED Natural Lighting |

| Observing System | Microscope |

| Parameters Memorization | 10 groups |

| Protection Alert | Yes |

| Language Display Options | English |

| Shield Gas Supply | One line quick connection (argon) |

| Cooling System | Water chiller |

| Running Environment | Temp 5°C – 30°C, Hum 5% – 75% |

| Machine Dimension | 1160X640X1410mm |

| Water Chiller Dimension | 740X600X1090mm |

| Weight (Unpackaged) | 200kg |

Pedestal Jewelry Laser Welding Machine: Precision Meets Performance ✨

Designed with the jewelry professional in mind, the Pedestal Jewelry Laser Welding Machine combines ergonomic design, advanced features, and unmatched precision to deliver flawless results every time.

💎 Key Features of the Pedestal Jewelry Laser Welding Machine:

Ergonomic Design for Comfort: The entire machine is ergonomically designed to meet the jewelry industry’s needs for precision, aesthetic appeal, stable performance, and the ability to handle long-duration and constant processing.

Spacious Interior for Tools & Fixtures: With ample inner space, you can easily store all your tools and fixtures, providing a clutter-free, organized workspace that enhances your productivity.

Smooth & Precise Operation: The machine is equipped with an electric focusing mechanism, digital scale reading display, and a regulating switch for laser parameters, ensuring smoother operation and consistent performance every time.

Easy Maintenance: The replaceable dust screen allows for easy cleaning of the work area, while the recycling system keeps your workspace clean by efficiently handling welding slag.

Clear Visibility for Precision Welding: Featuring an LED ring-shaped astral lamp for bright illumination and a high-quality German-imported microscope, the welding position is crystal-clear, enabling you to see even the finest details.

Precise Light Spot for Perfect Welds: The precise light spot ensures that the machine meets the highest standards of precision welding, making it perfect for delicate jewelry work.

🚀 Why Choose This Machine?

- Effortless Comfort with ergonomic design.

- Crystal-clear Observation for perfect results.

- Advanced Features for flawless, reliable welds.

Step up your jewelry game with the Pedestal Jewelry Laser Welding Machine—your ultimate tool for precision, efficiency, and long-lasting performance. 🌟

Applications of the Pedestal Jewelry Laser Welding Machine ✨

The Pedestal Jewelry Laser Welding Machine is an essential tool for a variety of industries, offering precision welding for a wide range of materials. Its versatility makes it a go-to solution in the following sectors:

💎 Key Applications:

- Aviation & Aerospace: Perfect for welding delicate components in high-precision industries.

- Jewelry: Ideal for silver, platinum, titanium, and stainless steel jewelry, including point welds, fill hole repairs, and setting precious stones and claw feet.

- Sports Equipment: Precision welding for golf club heads and other sporting goods.

- Medical Equipment: Used for welding medical devices and aluminum dentures, ensuring durability and accuracy.

- Electronics & Instruments: Essential for welding electronic parts and precision instruments.

- Automotive: A valuable tool in the automotive industry for welding various parts with precision.

With its advanced features, this machine can tackle even the most demanding welding tasks, making it indispensable across these industries. 🌟

FAQ – Pedestal Jewelry Laser Welding Machine

1️⃣ What is a Pedestal Jewelry Laser Welding Machine?

A Pedestal Jewelry Laser Welding Machine is a specialized device used for precision welding of metal parts, primarily for jewelry manufacturing and repair. It utilizes focused laser beams to melt and fuse metals without damaging the surrounding material, offering clean, precise, and efficient welding.

2️⃣ How does a Pedestal Jewelry Laser Welding Machine work?

The machine emits a highly focused laser beam that targets the joint area of the metals to be welded. The heat generated by the laser beam causes the metals to melt and bond together. It is commonly used for delicate tasks, such as repairing jewelry, resizing rings, or welding small components without disturbing the surrounding material.

3️⃣ What materials can be welded with this machine?

It is primarily used for welding precious metals such as gold, silver, platinum, and palladium, as well as other alloys and materials commonly found in jewelry making. It can also handle some base metals like copper and stainless steel, depending on the machine specifications.

4️⃣ What are the key advantages of using a Pedestal Jewelry Laser Welding Machine?

- Precision: The laser offers highly focused energy, making it ideal for small, delicate welds on intricate jewelry designs.

- Minimal Heat Affected Zone (HAZ): The laser’s precise control ensures minimal distortion and heat damage to the surrounding material.

- No Need for Filler Material: In many cases, the welding can be done without the need for additional filler material, preserving the appearance of the piece.

- Increased Efficiency: Fast welding times and reduced labor costs, leading to improved productivity.

- Clean Finish: The laser beam produces a clean, smooth weld without the need for post-processing.

5️⃣ Is the Pedestal Jewelry Laser Welding Machine easy to use?

Yes, the machine is designed to be user-friendly, with an intuitive control system. Many models come with touchscreens, adjustable settings for different materials, and fine-tuning capabilities for weld depth and power. Training is typically minimal, but learning the best settings for different types of jewelry may take a little practice.

6️⃣ What safety precautions should be taken when using the machine?

- Eye Protection: Always wear specialized laser safety glasses to protect your eyes from the intense light produced by the machine.

- Ventilation: Ensure proper ventilation to avoid inhaling fumes produced during the welding process, especially when working with alloys that may release hazardous fumes.

- Protective Gear: Wear appropriate clothing and gloves to avoid burns or injuries from the laser or hot metal.

7️⃣ Can I repair my jewelry with this machine?

Yes, Pedestal Jewelry Laser Welding Machines are commonly used for jewelry repair, including fixing broken clasps, resizing rings, reattaching stones, and more. Their precision allows for effective repairs without the need for extensive reworking of the piece.

8️⃣ What is the difference between a Pedestal Jewelry Laser Welding Machine and a standard laser welding machine?

The main difference lies in the design and function. A pedestal model is typically more compact and has a more ergonomic design, making it suitable for smaller, delicate pieces like jewelry. Standard laser welders may be larger and intended for more general applications, such as industrial or automotive welding.

9️⃣ How much does a Pedestal Jewelry Laser Welding Machine cost?

The cost varies depending on the brand, features, and specifications of the machine. Prices typically range from $5,000 to $20,000 USD. While the initial investment can be significant, the machine’s efficiency and the quality of the welds it produces can result in long-term savings and a return on investment.

🔟 What maintenance is required for the Pedestal Jewelry Laser Welding Machine?

Regular maintenance is necessary to keep the machine running smoothly:

- Clean the laser lens and mirrors regularly to ensure optimal performance.

- Check the cooling system to prevent overheating.

- Calibrate the machine periodically for accuracy.

- Replace any worn-out parts, such as laser tubes or fuses, as required.

Jewelry Laser Welding video

Request a Quote for a Jewelry Laser Welding Machine

SISMAR LASER has laser welding machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser welding system or an excellent choice for your first laser machine.

Request a quote for a high-quality jewelry laser welding machine that exceeds your expectations. You can also schedule a demo to see how jewelry laser welding machine works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

80W/100W/150W Fiber laser welding machine

/0 Comments/in Products /by linda

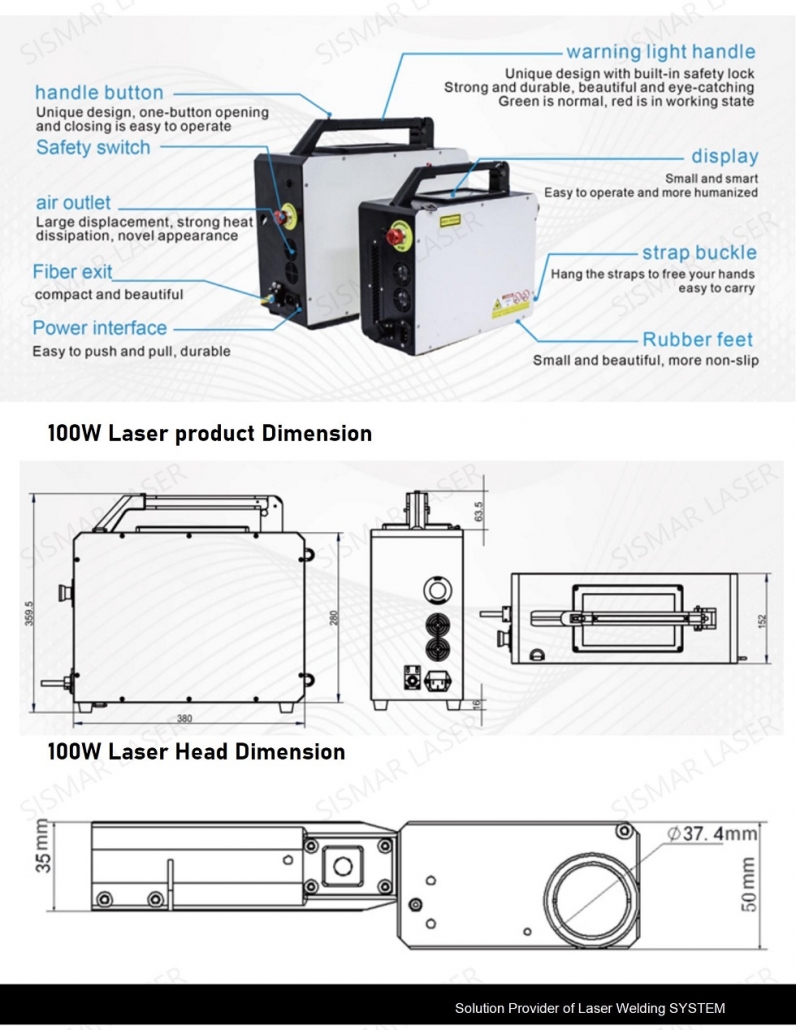

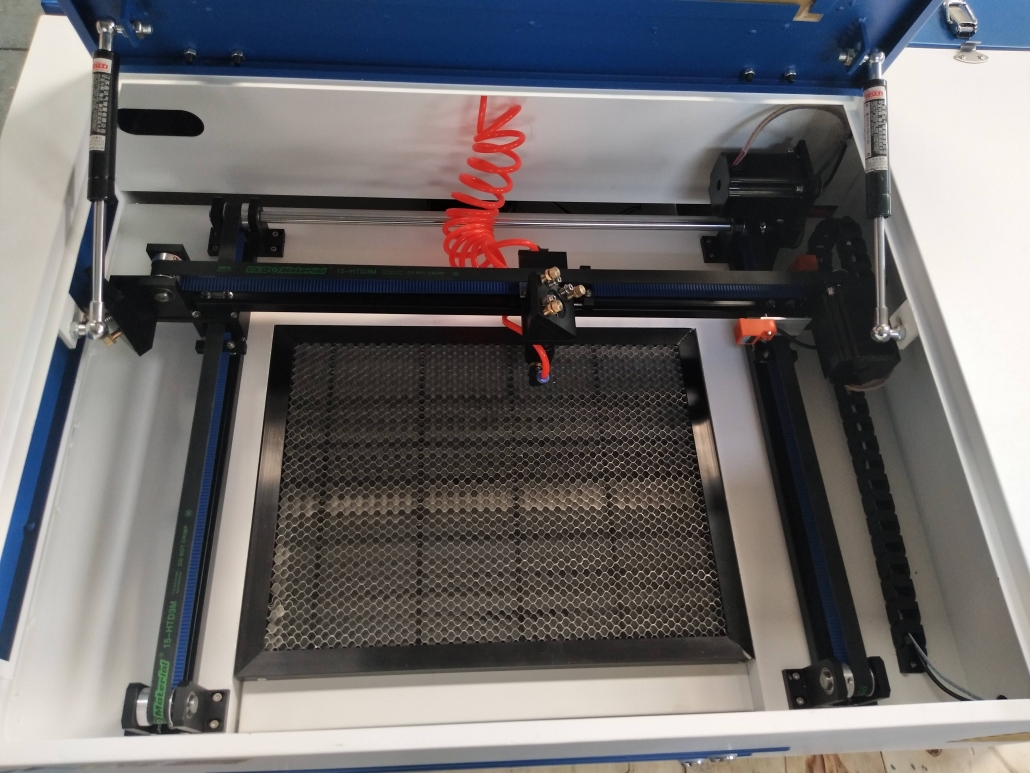

YAG/Fiber Laser Welding Machine Photo

100W fiber laser welding machine adopts imported lasers and cutting heads customized according to the jewelry industry. It has excellent laser beam quality and is suitable for cutting precious metals such as pure gold, 9K-24K gold, 925 silver, and pure silver.

100W Fiber welding machines can weld chains of different thickness and shape.

1. Fiber laser source model,small size,save working space and shipment cost.

2.Optional CCD camera monitoring system, easy to observe and precise positioning.

3. Adapt to a variety of complex welds, spot welding of various devices, and within 1mm sheet of seam welding.

4.High laser energy density, small thermal effect area, not easy deformation, less or no subsequent processing.

5.The unique fiber laser for firing uniformity over time

6.The best of components and electronics to ensure the best mechanical characteristics in each weld

7.Soft and constant spots that do not temper the metal

100W Fiber Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper – brass, titanium – gold, Titanium – molybdenum, nickel – copper and so on.

It can be applied to produce various chains, such as single clasp side chain, bismarck chain, curb chain, double chain, cross chain and twist chain.

Tab Content

Tab Content

100W Fiber Laser Welding Video

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

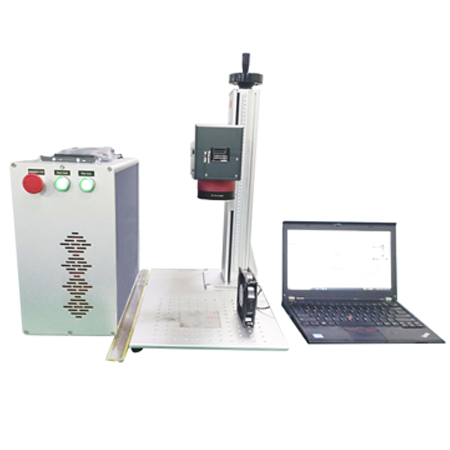

2.5D EZCAD 3.0 Fiber Laser Marking Cutting Machine

/0 Comments/in Products /by linda

2.5D Fiber Laser Marking Machine

2.5D EZCAD 3.0 Fiber Laser Marking Cutting Machine

2.5D EzCAD 3.0 Fiber Laser Engraving Machine

It is the upgrading system based on 2D laser.

Unlock precision with the 2.5D EzCAD 3.0 Fiber Laser. Engineered for 2D and 3D relief engraving on flat surfaces, this machine features motorized Z-axis auto-focus and advanced EZCAD 3.0 software for effortless, high-quality results. Perfect for fine details on metals, plastics, and more.

Note: It’s ideal for flat materials, but not for 3D engraving on curved surfaces.

Hot Selling Model of 2.5D Laser Marking Machine

Mini Fiber Laser

Mini Cover Fiber Laser

2.5D EZCAD 3.0 Laser detail info

2.5D EzCAD 3.0 Fiber Laser Marking & Engraving Machine – Advanced Laser Technology for Precision and Versatility

The 2.5D EzCAD 3.0 Fiber Laser Marking & Engraving Machine is the latest upgrade to the traditional 2D laser system, offering enhanced capabilities for both 2D and 3D laser engraving. This powerful machine integrates advanced features, including a motorized Z-axis auto-focus function and the EZCAD 3.0 software, designed specifically for 3D relief engraving on flat surfaces.

Key Features:

Motorized Z-Axis Auto Focus: This feature automatically adjusts the focus of the laser based on the surface of your material, ensuring optimal precision and consistency in engraving. Say goodbye to manual focus adjustments and save valuable time in your workflow.

EZCAD 3.0 Software: Known for its user-friendly interface, this upgraded software allows for effortless 3D relief engraving. The intuitive controls make it easy for operators to create complex designs, with unparalleled accuracy, on a wide variety of materials.

2D & 2.5D Engraving: While the 2.5D laser engraving machine excels in traditional 2D laser work, it also enables high-quality 3D relief engraving on flat surfaces. This provides added versatility compared to standard 2D systems, making it perfect for a variety of applications, including jewelry, metal, plastics, and more.

What You Need to Know:

2.5D Engraving Limitations: Although the 2.5D fiber laser engraving machine can handle 3D relief engraving on flat plates, it cannot perform true 3D engraving on curved or irregular surfaces. If you need to engrave 3D designs on complex geometries, a specialized 3D laser system may be more suitable.

Ideal for Multiple Industries: Whether you’re in jewelry design, metal engraving, or plastic marking, this machine offers the flexibility to handle a wide range of materials and applications. The combination of 2D precision and 3D relief engraving makes it a versatile tool for professionals looking to take their engraving capabilities to the next level.

Enhanced Productivity: With faster processing times and automated adjustments, the 2.5D fiber laser engraving machine streamlines production, allowing businesses to complete more projects in less time without compromising quality.

Why Choose the 2.5D EzCAD 3.0 Fiber Laser Engraving Machine?

Unmatched Precision: The motorized Z-axis auto-focus and EZCAD 3.0 software ensure perfect results every time, whether you are marking simple 2D designs or intricate 3D relief engravings.

Cost-Effective Solution: For businesses that require a high degree of engraving versatility without the high cost of a full 3D laser system, the 2.5D machine is the ideal compromise, offering a powerful solution for flat-surface 3D relief engraving at a more affordable price point.

Easy Integration into Your Workflow: The user-friendly interface and automated functions make it easy to integrate into existing production lines, boosting productivity without the need for specialized operators.

Parameters for the Mini Fiber Laser Engraving & Cutting Machine for Jewelry:

| Item | Specification |

|---|---|

| Laser Parameters | |

| Optical Maser | JPT M7 |

| Laser Wavelength | 1064nm |

| Average Output Power | 60W |

| Light Isolation | Yes |

| Modulation Frequency Range | 20kHz ~ 80kHz |

| Galvo Parameters | |

| Maximum Speed | 7000mm/s |

| Resolution | 0.001mm |

| Repositioning Precision | ±0.003mm |

| Optical Output Characteristics | |

| Marking Area | 110*110mm |

| Minimum Line Width | 0.01mm |

| Minimum Height of Characters | 0.2mm |

| Cooling System | |

| Cooling Way | Air Cooling |

| System Properties | |

| Laser Power Supply | 0.5KW/AC220V/50Hz~60Hz (optional 110V) |

| Environmental Requirements | 0 ~ 35°C, 90% humidity |

Whether you’re looking for a jewelry laser cutting machine for custom engravings, personalized jewelry marking, or professional gold and silver cutting, the Mini Fiber Laser Marking Machine is the best choice to elevate your business and increase your production capabilities.

Advantages: 2.5D EzCAD 3.0 Fiber Laser Marking & Engraving Machine

Precision Auto-Focus

Equipped with a motorized Z-axis auto-focus, this machine automatically adjusts the focal distance based on the material surface, ensuring optimal engraving results and saving you time on manual adjustments.2D & 3D Engraving Capabilities

The 2.5D machine not only handles 2D laser engraving but also supports 3D relief engraving on flat surfaces, making it ideal for intricate designs on metals, plastics, wood, and more.EZCAD 3.0 Software Integration

Powered by EZCAD 3.0 software, it offers easy-to-use controls and powerful features for creating detailed, high-precision 3D relief effects, allowing you to take your designs to the next level with ease.High-Efficiency Production

With fast engraving speeds, this machine can significantly boost production efficiency, making it perfect for businesses needing high-output with consistent quality.Versatile for Multiple Materials & Industries

Whether you’re working with jewelry, metal plaques, plastic marking, or other materials, the 2.5D EzCAD 3.0 Fiber Laser Machine delivers exceptional performance, making it a versatile solution for various industries.Cost-Effective Solution

Combining 2D and 3D engraving functions into one machine, this solution offers the best of both worlds at a more affordable price than standalone 3D laser systems, giving you more value for your investment.

Applications of the 2.5D EzCAD 3.0 Fiber Laser Marking Machine

The 2.5D EzCAD 3.0 Fiber Laser Marking Machine is designed for high-precision metal marking and engraving, offering both 2D and 3D relief engraving on flat metal surfaces.

Key Applications:

Jewelry Marking: Ideal for engraving intricate designs, logos, and text on metal jewelry like rings and bracelets. It supports 3D relief effects for added detail.

Metal Parts & Components: Perfect for marking serial numbers, barcodes, and logos on metal parts in industries like automotive, aerospace, and electronics.

Plaques & Tags: Engrave nameplates and metal tags with precision and 3D relief effects for enhanced branding.

Industrial & Electronic Marking: Ideal for marking metal parts in industries requiring durability, such as electronics, automotive, and aerospace.

Custom Gifts & Promotional Items: Perfect for engraving personalized metal gifts, trophies, and promotional items with 3D effects for a unique, high-end finish.

Why Choose the 2.5D EzCAD 3.0?

- High Precision on metal surfaces.

- 3D relief engraving for added depth and detail.

- Fast, durable, and cost-effective for high-volume production.

Frequently Asked Questions (FAQ) – 2.5D Fiber Laser Marking Machine

1️⃣ What is a 2.5D Fiber Laser Marking Machine?

A 2.5D Fiber Laser Marking Machine is a high-precision laser system that combines the benefits of traditional 2D laser marking with depth control for more complex designs. This technology allows for engraving or marking that includes depth variations, making it ideal for creating 3D-like effects, such as relief marking, logo engraving, and barcodes on curved or uneven surfaces.

2️⃣ How is a 2.5D Fiber Laser Marking Machine different from a 2D system?

While traditional 2D laser marking is flat and only provides surface engraving, a 2.5D fiber laser adds the ability to control the depth of the engraving. This allows for more intricate designs and three-dimensional effects on materials, making it suitable for deep engraving, textured surfaces, or part marking on non-flat objects.

3️⃣ What materials can the 2.5D Fiber Laser Marking Machine process?

This machine is designed to work with a wide range of materials, including:

- Metals: Steel, aluminum, copper, titanium, gold, silver, etc.

- Plastics: ABS, PVC, polycarbonate, etc.

- Ceramics: Tiles, porcelains, etc.

- Glass: For engraving logos or creating 3D designs.

- Composites: Carbon fiber, fiberglass, etc.

The depth control makes it especially effective for processing harder materials and creating intricate details.

4️⃣ How does the depth control work in a 2.5D Fiber Laser Marking Machine?

The depth control works by adjusting the focus and laser power to vary the engraving depth. By precisely controlling the laser’s movement and focus point, the system can create shallow or deep marks, allowing for detailed relief engraving, textures, and logos on uneven or curved surfaces. The machine can also adjust the depth of engraving on multi-layered materials for more complex projects.

5️⃣ What are the key advantages of using a 2.5D Fiber Laser Marking Machine?

- High Precision: Achieve extremely accurate marks with high depth control for a 3D effect on materials.

- Versatile Applications: Ideal for marking or engraving on irregular surfaces such as cylindrical, curved, or 3D parts.

- Deep Engraving: Offers the ability to engrave deeper than traditional 2D machines, perfect for texturing, logos, or serial numbers.

- Clean & High-Quality Results: Produces smooth, clean marks with no residue, reducing the need for post-processing.

- Cost-Effective & Efficient: The fiber laser is energy-efficient, provides fast processing, and ensures long-term durability with minimal maintenance.

6️⃣ What are some common applications for the 2.5D Fiber Laser Marking Machine?

The 2.5D fiber laser is perfect for applications where depth, texture, or relief is required:

- Aerospace: Engraving detailed part markings, serial numbers, or logos on curved or irregular parts.

- Automotive: Marking VIN numbers, engine parts, and custom designs on metal and plastic components.

- Electronics: Creating detailed engravings on circuit boards, chips, and connectors.

- Jewelry: Engraving intricate designs or 3D logos on rings, necklaces, and bracelets.

- Medical Devices: Engraving serial numbers or labels on medical instruments and implants.

- Tooling & Manufacturing: Marking parts and tools with barcodes or technical data.

7️⃣ What is the marking area of the 2.5D Fiber Laser Marking Machine?

The marking area generally ranges from 50mm x 50mm to 300mm x 300mm, depending on the specific model. Some models may offer customizable marking sizes to accommodate larger or more complex components.

8️⃣ Is the 2.5D Fiber Laser Marking Machine easy to operate?

Yes, the 2.5D Fiber Laser Marking Machine comes with user-friendly software and an intuitive control interface. The machine allows for easy depth adjustments, pattern uploads, and real-time monitoring of the engraving process. Additionally, it’s designed to require minimal training, making it suitable for both beginners and professionals.

9️⃣ Can the 2.5D Fiber Laser Marking Machine be used for batch production?

Yes, the 2.5D Fiber Laser Marking Machine is ideal for batch production. Its high-speed operation and precision allow for continuous processing of multiple parts, making it suitable for high-volume production lines. The automatic depth control ensures consistent quality across all pieces.

🔟 How does the machine handle materials of different thicknesses or sizes?

The 2.5D Fiber Laser Marking Machine can easily adjust its focus to accommodate different thicknesses and sizes of materials. The focus lens can be changed, and the laser power can be adjusted to create the desired engraving depth and quality, regardless of the material’s thickness. This flexibility makes it ideal for multi-material production and handling a variety of products.

1️⃣1️⃣ What maintenance is required for the 2.5D Fiber Laser Marking Machine?

Routine maintenance includes:

- Cleaning the lens and mirrors to maintain optimal performance.

- Inspecting the laser for any signs of wear.

- Checking the cooling system to ensure the machine operates at the right temperature.

- Periodically calibrating the system to maintain depth accuracy.

- Software updates for new features or improvements.

1️⃣2️⃣ How much does a 2.5D Fiber Laser Marking Machine cost?

The price varies depending on the laser power, marking area, and specific features such as depth control and additional customizations. Generally, the price range is between $15,000 to $60,000, depending on the configuration and requirements.

2.5D EZCAD 3.0 Fiber Laser Laser Marking Cutting Video

Request a Quote for a Green Laser Marking Machine

SISMAR LASER has green laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

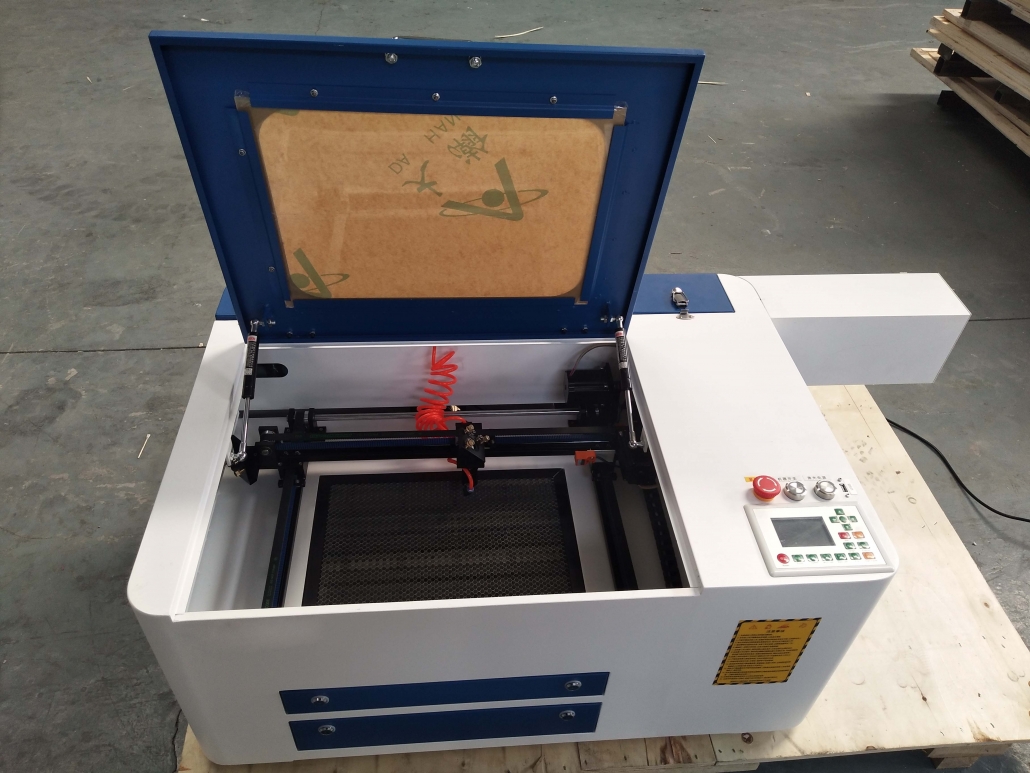

Handheld Laser Cleaning Machine

/0 Comments/in Products /by linda

Portable/Handheld Laser Cleaning Machine

The Backpack handheld pulsed laser cleaning machine for rust paint oil removal portable laser cleaner,also called Laser Rust Removal System.

1. 50w 100W backpack handheld laser cleaning machine is a “Environmental friendly” cleaning machine. It does not need to use any chemicals and cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve chemical cleaning problems.

2. Its biggest advantage is that it is light and portable. Compared with large machines, it is more suitable for home use, does not take up space, and is easy to operate. Using laser technology to quickly peel off rust, oil, paint, and a wide range of applications.

The backpack laser cleaning machine is a pulsed Gaussian laser cleaning machine with the minimum power (50W/100W)

At the same time, it is equipped with the function of a backpack. If you go out for cleaning services, or take it out to meet customers, it is a very good economical pulsed laser cleaning machine.

The weight of the whole machine is not To 8 kg, anyone can learn and use it within 1 hour without any skills and professional skills.

Advantage of Handheld/Portable Laser Cleaning Machine

- It’s a non-contact, non-abrasive process. Home remedies are messy and unhealthy. Scrubbing off rusted surfaces exposes you to impurities which could lead to respiratory complications. Laser cleaning, on the other hand, relies on the laser beam to ablate the surface. There is no physical contact between you and the rust.

- No use of chemicals. Rust remover chemicals can get the job done, but the health implications on their use outweigh their benefit. Such chemicals are not only harsh and abrasive but also emit intense fumes. You will need to wear protective gear such as a respirator, goggles and rubber gloves before using them. However, laser cleaning does not rely on any chemical application. It is the better choice as it does not put your health at risk.

- No secondary waste is produced. Scrubbing off rust from surfaces only disintegrates the rusty particles from the substrate, leaving you with a toxic lump of rust dust at the end of the process. Electrolysis leaves the rust particles floating in the water, which you later have to dispose of. In comparison, laser cleaning is a cleaner process as the rust particles are either vaporized or turned into plasma, leaving no evidence of waste.

- High precision. The focused laser beams have an extremely precise focal edge, allowing you to ablate rust from tough spots that would otherwise be harder to clean with other apparatus. Such include the rust that develops around bolts and rails. Additionally, the high precision allows you to focus the laser beam repeatedly over a specific area to achieve the required depth and result.

- It’s effective on all surfaces. Unlike other rust removal procedures, laser cleaning works on all surfaces that are prone to rusting, including stones, concrete, iron, aluminum (bauxite) or copper.

- It does not degrade the substrate. Scrubbing rusted surfaces significantly degrades the substrate due to friction. Rust removing chemicals, on the other hand, are harsh and corrosive, causing wear and tear that could spoil delicate metals or even weaken their robustness. Laser cleaning in comparison ablates the surface while leaving the substrate untouched.

- It is a long-term solution. A laser cleaning machine will serve you longer than any scrubber or rust removing chemical will. The laser does not suffer any wear or tear, and thus can be used and reused over its lifetime.

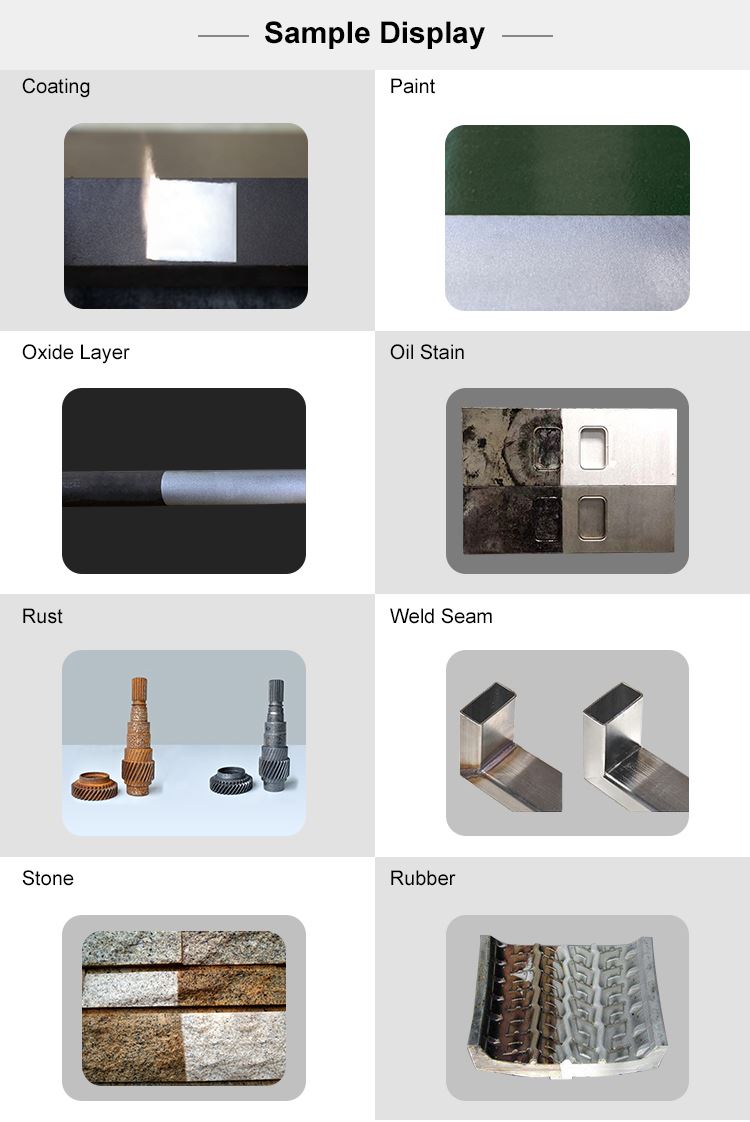

1.Metal surface rust,

2.Surface paint stripping treatment,

3.Surface oil, stains, dirt cleaning,

4.Surface coating, coating removal,

5.Welding surface / spray surface pretreatment,

6.Stone surface dust and attachments removed,

7.Rubber mold residue cleaning.

Videos of Backpack laser cleaning machine

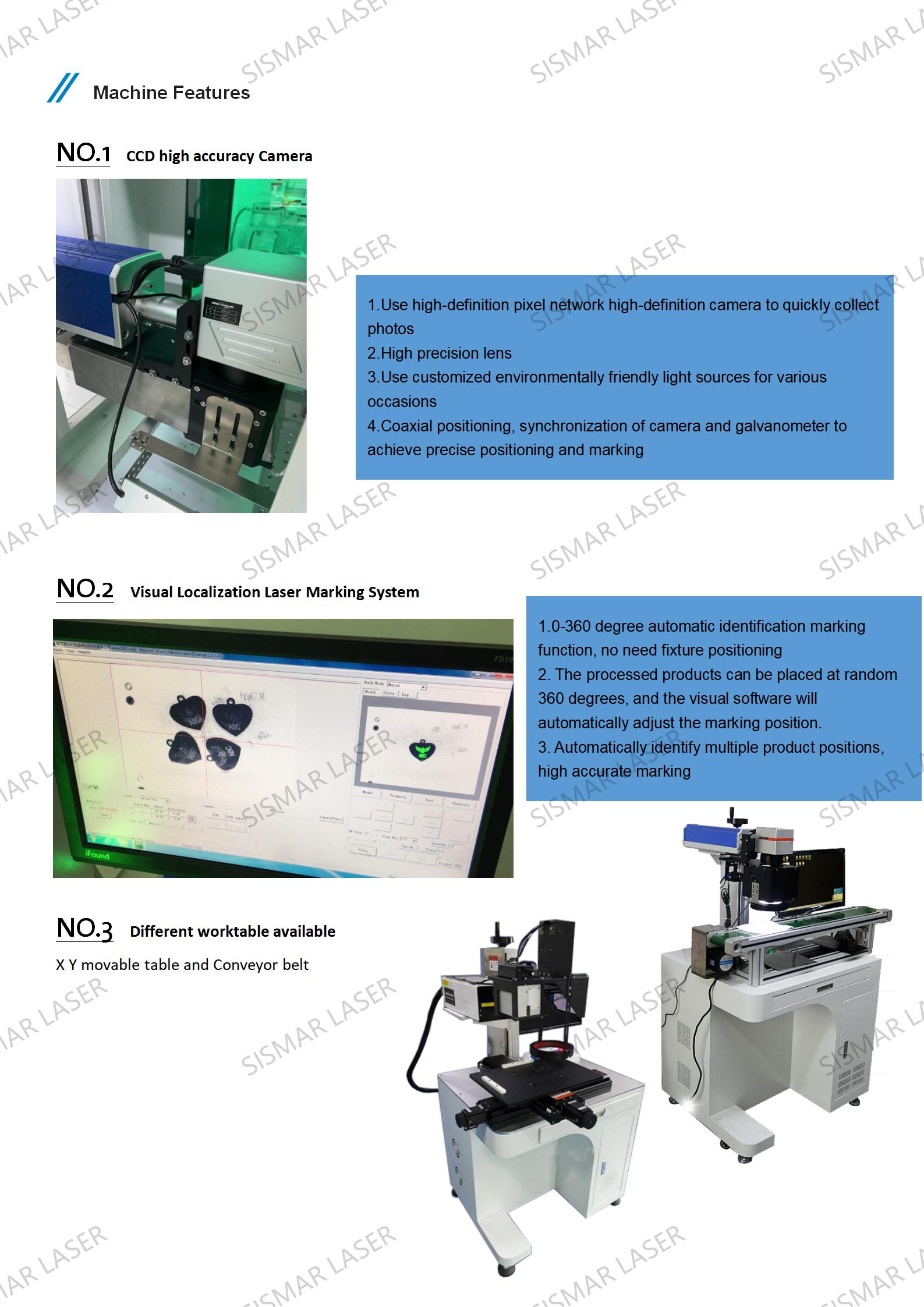

CCD Visual Localization Laser Marking Machine

/0 Comments/in Products /by linda

CCD Visual Position Laser Marking Machine

CCD Laser Marking Machine: The Ultimate Solution for Zipper Manufacturers

Is your zipper marking process plagued by low efficiency and high costs? Our CCD Laser Marking Machine is the ultimate solution designed specifically for zipper manufacturers.

The core advantage of this machine lies in its CCD vision recognition system, which automatically locates and precisely marks zippers without any manual placement. This means you can say goodbye to tedious manual operations and achieve fully automatic batch production for your zippers.

It’s not only incredibly fast but also highly precise, capable of marking intricate patterns and tiny text on zippers with clarity and permanence. Choosing our CCD Laser Marking Machine means choosing higher efficiency, lower costs, and superior product quality for every zipper you produce.

CCD visual Position Laser Marking Machine Photo

As a zipper manufacturer, are you looking for a solution to overcome traditional marking challenges, improve production efficiency, and enhance product quality? You may be facing these common pain points:

Low Efficiency: Traditional marking methods require manual, step-by-step operation, which is slow and significantly impacts delivery times, especially for large orders.

Insufficient Precision: Manual operation often leads to positional deviations and inconsistent, blurry patterns, affecting product aesthetics and leading to rework and material waste.

Batch Processing Difficulties: Different sizes and shapes of zippers require frequent jig changes, preventing automated, continuous production.

High Labor Costs: Over-reliance on manual labor increases costs and raises the defect rate due to operator errors.

We understand your frustrations. That’s why we bring you the CCD laser marking machine, specifically tailored for zipper manufacturers. It’s not just a piece of equipment; it’s a complete solution to boost your core competitiveness.

How the CCD Laser Marking Machine Solves Your Pain Points

1. Core Advantage: Fully Automatic Recognition & High-Speed Marking

Our CCD laser marking machine for zipper is equipped with an advanced visual positioning system. It automatically captures and precisely identifies different workpieces like zipper pulls and sliders, allowing for jig-free marking. Simply load zippers in bulk, and the machine will automatically recognize and mark them, achieving a truly automated, unmanned production model.

2. Core Advantage: A Perfect Blend of Speed and Precision

The machine uses high-speed galvanometer technology, with marking speeds far exceeding traditional methods, capable of marking hundreds or even thousands of zippers per minute. At the same time, the laser marking precision reaches the micron level, ensuring that complex logos, tiny text, and high-definition QR codes are permanently and clearly marked on the zipper surface, significantly enhancing your product’s premium feel and anti-counterfeiting capabilities.

3. Core Advantage: Versatile and Highly Adaptable

This zipper laser marking solution is not only suitable for various materials like metal, plastic, and nylon but also easily handles different sizes, shapes, and colors of zippers. The software interface is intuitive and easy to use, allowing you to quickly switch between different marking tasks without complex adjustments.

Product Specifications (For Reference)

| Parameter | Technical Specification |

| Laser Type | Fiber Laser |

| Laser Power | 50W |

| Marking Area | 110mm x 110mm (Customizable) |

| Marking Speed | ≤ 7000mm/s |

| Marking Precision | ±0.001mm |

| Working Voltage | AC220V±10% / 50Hz |

| Cooling Method | Air Cooling |

| Vision System | CCD Automatic Recognition and Positioning System |

| Supported File Formats | PLT, DXF, BMP, JPG, CDR, AI, etc. |

| Software System | Dedicated Laser Marking Software |

Broad Range of Applications

Our CCD laser marking machine is not just the perfect zipper manufacturer solution; it’s also ideal for the following industries and products:

Apparel Accessories: Marking on buttons, belt buckles, hardware, etc.

Electronic Products: Marking on phone cases, chargers, data cables, headphones, etc.

Hardware Tools: Marking on screws, wrenches, knives, bearings, etc.

Jewelry: Engraving patterns and text on rings, necklaces, bracelets, etc.

Medical Devices: Marking on scalpels, screws, etc., for traceability and branding.

Zipper Marking: A Comprehensive Comparison Between CCD Laser Marking and Traditional Methods

In the zipper manufacturing industry, choosing the right marking technology is crucial for boosting efficiency and product value. Traditional methods like ink printing and mechanical engraving have significant performance differences when compared to the modern CCD Laser Marking Machine. Here’s a detailed comparison of the two across key production aspects.

1. Automation and Production Efficiency

Traditional Methods (Ink Printing / Mechanical Engraving)

Highly reliant on manual labor: Requires workers to manually place and align zippers one by one, making automation impossible.

Low efficiency: The cumbersome process significantly slows down overall production, especially for large-volume orders, affecting delivery times.

CCD Laser Marking Machine

Fully automated and unmanned: Thanks to its CCD vision recognition system, the machine automatically captures and locates zippers scattered on a tray or conveyor belt, eliminating the need for manual alignment.

Ultra-fast batch production: It can mark multiple zippers within its field of view simultaneously, enabling a “load and mark” automated workflow that increases production efficiency by several times.

2. Marking Quality and Precision

Traditional Methods (Ink Printing / Mechanical Engraving)

Limited precision: Ink printing often results in blurry patterns and unclear edges, affecting the product’s aesthetic. Mechanical engraving can leave burrs and scratches, damaging the zipper’s surface.

Non-durable marks: Ink marks can easily fade, wear off, or rub away due to friction and cleaning, failing to provide a permanent solution.

CCD Laser Marking Machine

High precision with no deviation: The laser beam has a micron-level spot size, allowing it to precisely mark complex logos, tiny text, or QR codes. Each mark is flawless and sharp.

Permanent marking: The laser creates a mark by physically or chemically altering the material’s surface. This makes the marks highly resistant to wear, corrosion, and weathering, ensuring they never fade and enhancing the product’s quality and anti-counterfeiting features.

3. Cost and Maintenance

Traditional Methods (Ink Printing / Mechanical Engraving)

High consumable costs: Requires a continuous purchase of ink, solvents, printing plates, or cutting tools, leading to high long-term operational costs.

Complex maintenance: Equipment needs regular cleaning, and parts like blades or plates need to be replaced, making maintenance time-consuming and cumbersome.

CCD Laser Marking Machine

Zero consumables: As a non-contact process, laser marking produces no consumables, significantly reducing operational costs.

Simple maintenance: The machine has a stable structure. Routine maintenance is minimal, usually just requiring periodic lens cleaning, with virtually no additional maintenance expenses.

4. Flexibility and Environmental Impact

Traditional Methods (Ink Printing / Mechanical Engraving)

Low flexibility: Changing the marking content or design requires new plates or tooling, which is time-consuming and costly.

Environmental pollution: Ink and solvents contain volatile organic compounds (VOCs) that are harmful to the environment and worker health.

CCD Laser Marking Machine

Highly flexible: You can quickly change marking content in the software without any physical adjustments, allowing you to adapt to diverse order requirements easily.

Eco-friendly and pollution-free: The marking process doesn’t produce any chemical waste or pollutants, making it a clean and environmentally friendly manufacturing method.

Conclusion:

The CCD Laser Marking Machine has become the preferred solution for zipper marking due to its clear advantages in automation, precision, low cost, and environmental friendliness. It helps businesses significantly boost production efficiency and product quality while effectively reducing operational costs, allowing them to stay ahead in a competitive market.

Frequently Asked Questions (FAQ)

1. What’s the difference between a CCD laser marking machine and a regular one?

The biggest difference is the CCD vision system. Regular laser markers require a worker to manually align each part, one at a time, which is slow. A CCD laser marker uses its vision system to automatically identify and locate multiple or irregularly placed items at once, enabling true automated batch production.

2. Will laser marking damage the zipper’s surface or material?

No, it won’t. Laser marking is a non-contact process. It uses a high-energy laser beam to create a permanent mark on the material’s surface without causing any physical damage or deformation to the zipper itself. We offer different laser types for various materials like metal, plastic, and nylon to ensure a flawless, non-destructive mark.

3. Will the laser mark fade or wear off over time?

No. Laser marking is permanent. It alters the material’s surface through a physical or chemical reaction, making the mark highly resistant to wear, corrosion, and weathering. The mark won’t fade over time, which also helps with product authenticity and traceability.

4. Is the equipment’s maintenance expensive?

The maintenance cost is very low. A laser marker is a no-consumable device, meaning you won’t need to buy ink, solvents, or cutting tools. Routine maintenance is simple, typically only requiring you to clean the lens, so there are virtually no extra maintenance costs.

5. Is the machine difficult to operate? Will my workers learn quickly?

The software interface is simple and intuitive, making the machine very easy to operate. We provide comprehensive manuals, video tutorials, and professional training to ensure your workers can quickly learn to use the equipment efficiently.

6. What kind of after-sales service do you offer if the equipment has an issue?

We provide a complete after-sales service system, which includes remote technical support, online diagnostics, and on-site repair services. Our professional technical team will respond quickly to ensure your production line runs smoothly and reliably.

7. What types of zippers can your equipment mark?

Our equipment can mark all kinds of zippers and materials, including metal, resin, and nylon zippers, as well as various special shapes of zipper pulls and sliders.

CCD Visual Position Laser Marking Video

Request a Quote for a CCD Visual Position Laser Marking Machine

SISMAR LASER has CCD visual Position laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

3D Fiber Laser Marking Machine

/0 Comments/in Products /by linda

3D Laser Marking Solutions

Precision 3D Laser Marking Machines for Industrial Applications

3D Fiber Laser Marking Machine

The 3D Fiber Laser Marking Machine is the ultimate solution for marking on complex surfaces. It combines all the benefits of a 2D laser system and adds the ability to mark on spherical objects, curved surfaces, and even 45-degree angles. With high precision and dynamic focus adjustment, this machine delivers detailed, durable markings on a wide range of materials, including metal, plastic, and ceramics. Perfect for industries requiring versatile and high-quality laser engraving.

3D Fiber Laser Engraving Cutting Machine Models

Elevate Your Marking and Cutting Capabilities with 3D Laser Technology

Unlock new dimensions in precision and efficiency with our 3D Fiber Laser Marking Machine. Designed to handle flat surfaces, intricate 3D designs, and even precious materials like gold and silver, this machine offers unparalleled versatility and speed.

Key Features:

Curved Surface Marking: Effortlessly mark on curved surfaces and spherical objects with exceptional precision, surpassing traditional rotary marking methods.

3D Deep Engraving: Achieve deep, intricate engravings on various materials, including metal, plastic, and ceramic, with ease and efficiency.

Large Format Laser Marking: Handle larger projects with a 300mm x 300mm plane marking area and 150mm x 150mm x 60mm curved marking capacity, ensuring consistent quality across extensive surfaces

Laser Cutting for Precious Materials: Precisely cut gold, silver, and other precious metals, ensuring clean, smooth cuts ideal for jewelry making and custom designs.

Advantages Over Traditional 2D Laser Marking:

Dynamic Focus Tracking: Real-time tracing of deep curves and precise focusing areas ensures consistent accuracy across complex surfaces.

Enhanced Efficiency: Experience significantly improved speed without compromising quality, streamlining your production process.

Versatile Marking Modes: Mark on oblique planes, circular cones, spherical surfaces, and extruded shapes, redefining traditional marking capabilities.

Explore New Possibilities with 3D Laser Technology

Embrace the future of engraving and cutting with our 3D Laser Marking Machine. Whether you’re creating intricate engravings, marking complex surfaces, or cutting precious metals, this machine offers unmatched precision, speed, and versatility. Break free from the limitations of traditional 2D marking and elevate your work to new heights.

For more information or to request a demonstration, contact us today.

model | SL-3D30W | SL-3D50W | SL-3D100W |

Output power | 30W | 50W | 100W |

Pulse power | 1MJ | 1MJ | 1MJ |

Repetitive Rate | 30K-200KHZ | 50K-200KHZ | 50K-200KHZ |

Wavelength | 1064nm | ||

Guide laser | Red light/655nm wavelength/output1.0mw | ||

Marking range | 140mm*140mm | ||

Optional marking range | 70mm*70mm/100mm*100mm/170mm*170mm/200mm*200mm/300mm≤400mm | ||

Hight/Depth range | ±20mm | ||

Marking model | XYZ axis dynamic focusing | ||

Min line width | 0.03mm | ||

Marking speed | ≤10000mm/s | ||

Operate system | WIN7/WINXP | ||

Support font | True type,AUTOCAD,Others | ||

1D barcode | CODE39/CODE128/TIF/CODABAR/EAN/UPC | ||

2D barcode | QR/PDF417/DATA Matrix(ECC220) | ||

Support format | PLT/DXF/DWG/SVG/STL/BMP/JPG/PNG/TIF | ||

Working environment | Temperature:10℃-35℃ Humidity 5%/75% | ||

Power consumption | Single phase 110v/220v optional/50-60HZ | ||

Cooling way | Air cooling | ||

1. Comparison of Laser Marking Machine Types:

| Feature | 3D Laser Marking Machine | 2D Laser Marking Machine | 2.5D Laser Marking Machine |

|---|---|---|---|

| Working Principle | Uses dynamic focus tracking, capable of marking complex 3D surfaces like inclined, spherical, and concave surfaces. | Primarily used for flat or simple curved surfaces, not capable of handling complex 3D shapes. | Suitable for 2D marking and flat relief, able to handle simpler relief effects. |

| Surface Type | Can mark flat, curved, spherical, conical, and other complex 3D surfaces. | Only flat surfaces. | Suitable for flat relief and some simple curved surface marking. |

| Depth Control | Offers depth control, perfect for deep 3D engraving and curved surface relief. | Suitable for regular deep engraving but cannot create relief effects. | Suitable for flat relief and shallow engraving, providing different depth effects. |

| Precision | High precision, ideal for complex 3D engravings and curved surface relief. | High precision, ideal for flat marking and simple deep engravings. | High precision, suitable for flat relief and some basic 3D relief. |

| Materials | Can be used on metals, plastics, ceramics, etc., especially for complex surfaces and deep engravings. | Suitable for metals, plastics, etc., ideal for flat marking and deep engraving. | Suitable for metals, plastics, ceramics, etc., ideal for flat relief and shallow engravings. |

| Processing Speed | Generally slower, suitable for complex curved surface and deep engraving tasks. | Faster, suitable for large-volume deep engraving tasks. | Moderate speed, suitable for flat relief and shallow engraving tasks. |

| Application Scenarios | Ideal for complex surface relief, deep engraving, and fine marking tasks such as jewelry, aerospace, medical equipment, etc. | Suitable for regular deep engraving, such as marking simple signage, tools, and electronic products. | Ideal for flat relief effects, artistic engraving, decorative marking, etc. |

2. Summary:

- 3D Laser Marking Machine: Capable of performing all the tasks of 2.5D and curved surface relief, perfect for high-precision, deep engraving, and complex surface marking applications.

- 2D Laser Marking Machine: Primarily used for flat deep engraving tasks, faster speed, suitable for simple deep engraving applications in large-scale production.

- 2.5D Laser Marking Machine: Handles 2D marking and flat relief, suitable for fine flat engravings and simpler relief applications.

All three types of laser marking machines can be used for cutting and marking gold and silver, allowing you to choose the right machine based on your specific needs.

Transform Your Marking & Engraving with 3D Laser Technology!

The 3D Laser Marking Machine is designed to handle complex surfaces and deliver high-precision results across a variety of applications. From intricate jewelry engraving to cutting-edge aerospace components, this machine redefines the way you work with materials. Let’s explore the top applications:

1. Jewelry Marking & Engraving 💍

Precision for Every Piece

The 3D Laser Marking Machine is perfect for custom jewelry designs. It allows you to engrave intricate details and mark curved surfaces on rings, necklaces, bracelets, and more.

- Custom designs on spherical, flat, and complex shapes.

- Engraving serial numbers and logos with high accuracy.

2. Aerospace & Automotive Components ✈️🚗

Mark Complex Parts with Ease

Whether you’re marking turbine blades or engine parts, the 3D Laser Marking Machine handles detailed information on complex surfaces.

- Precise serial numbers and barcodes on curved and intricate surfaces.

- High-quality results for critical aerospace and automotive components.

3. Medical Devices & Equipment 🏥

Ensuring Safety & Compliance

In the medical field, every engraving must be precise and reliable. The 3D Laser Marking Machine is used to engrave serial numbers, logos, and safety markings on medical tools, implants, and diagnostic devices.

- Traceability and compliance for medical-grade equipment.

- Engraving on curved or delicate surfaces with precision.

4. Custom & Artistic Engraving 🎨

Unleash Your Creativity

Artists and designers can create intricate 3D engravings on a variety of materials, including wood, leather, glass, and metal. The 3D laser makes it easy to mark custom patterns and artistic designs.

- Engrave detailed 3D designs with exceptional clarity.

- Perfect for personalized and one-of-a-kind art pieces.

5. Electronics & Microelectronics 🔌

Marking Tiny Components with Precision

For small parts like PCBs, semiconductors, and connectors, the 3D Laser Marking Machine provides flawless markings on micro-sized components.

- No material damage—perfect for delicate electronic parts.

- High precision for tiny, complex engravings.

6. Tool & Mold Marking 🛠️

Mark Every Tool & Mold with Precision

In industrial manufacturing, marking tools and molds with serial numbers, part numbers, and logos is crucial. The 3D Laser Marking Machine handles intricate details on every part.

- Long-lasting results for industrial components.

- Perfect for traceability and quality control.

7. Optical Components & Lenses 👓

Precision Engraving for Optical Components

Whether you’re marking lenses, optical mirrors, or other precision instruments, the 3D Laser Marking Machine delivers high-quality results.

- Engrave logos, barcodes, and precision measurements.

- Perfect for curved optical surfaces.

8. Metal & Precious Material Cutting 💎

Precision Cutting Without Compromise

The 3D Laser Marking Machine is ideal for cutting gold, silver, and platinum with clean, smooth edges.

- High-precision cutting for luxury items and custom jewelry.

- Engraving and cutting precious metals with zero material damage.

9. Custom Nameplates & Tags 🏷️

Make Your Brand Stand Out

Create personalized nameplates, tags, and labels with intricate engravings and high-definition details.

- Custom designs for branding and personalization.

- Marking on a variety of materials with high precision.

Why Choose the 3D Laser Marking Machine?

The 3D Laser Marking Machine is the ultimate tool for industries that demand precision, versatility, and efficiency. Whether you’re marking intricate designs on jewelry, cutting precious metals, or engraving complex aerospace parts, this machine delivers outstanding results every time.

Unlock new possibilities with 3D Laser Technology—take your marking and engraving to the next level today! 🚀

Frequently Asked Questions (FAQ)

1️⃣ What is a 3D Fiber Laser Marking Machine?

A 3D Fiber Laser Marking Machine uses advanced fiber laser technology to engrave, mark, and etch three-dimensional designs on various materials. Unlike traditional 2D marking machines, it allows for intricate and precise 3D engraving on curved, uneven, or complex surfaces like metal, plastic, ceramics, and more.

2️⃣ How does a 3D Fiber Laser Marking Machine work?

The machine utilizes a fiber laser beam that focuses on the surface of the material. It then scans the surface in multiple directions to create deep, detailed engravings. The 3D aspect comes from its ability to work with three-dimensional surfaces, enabling engraving on curved, angled, or contoured items without compromising precision.

3️⃣ What materials can a 3D Fiber Laser Marking Machine mark?

This machine is highly versatile and can mark a wide range of materials, including:

- Metals (stainless steel, aluminum, gold, silver, etc.)

- Plastics (ABS, PC, PVC)

- Ceramics

- Glass

- Wood

- Leather

- Anodized metals

It can handle both hard and soft materials, making it perfect for industrial and personalized applications.

4️⃣ How is 3D marking different from traditional 2D marking?

While 2D laser marking is limited to flat surfaces, the 3D Fiber Laser Marking Machine can work on curved, angled, and uneven surfaces, enabling the creation of intricate, three-dimensional designs. This opens up possibilities for highly detailed engravings on complex parts, including jewelry, tools, and medical devices.

5️⃣ What industries benefit from using a 3D Fiber Laser Marking Machine?

The 3D Fiber Laser Marking Machine is used across many industries, including:

- Automotive (marking serial numbers, logos, and part numbers)

- Aerospace (engraving technical markings on parts)

- Jewelry (custom engravings on rings, bracelets, and pendants)

- Medical (marking surgical instruments, implants)

- Electronics (engraving serial numbers, barcodes, and logos)

- Tooling & Manufacturing (engraving part numbers and dimensions on tools)

6️⃣ Can the 3D Fiber Laser Marking Machine handle high-volume production?

Yes, this machine is ideal for high-volume production. It provides fast engraving speeds while maintaining high precision over long periods of operation. With automated controls, it can mark hundreds to thousands of parts quickly and consistently, making it perfect for industrial applications.

7️⃣ How precise is the engraving on a 3D Fiber Laser Marking Machine?

The 3D Fiber Laser Marking Machine offers exceptional precision, with the ability to engrave detailed micro-sized patterns (down to 0.01mm). The focus and resolution of the laser beam ensure that highly intricate designs are replicated with great accuracy on both flat and 3D surfaces.

8️⃣ What are the benefits of using a 3D Fiber Laser Marking Machine?

Some of the key benefits include:

- High precision for detailed and intricate designs

- Ability to engrave complex 3D shapes without distortion

- No material wear like traditional engraving methods

- Minimal heat-affected zone for delicate materials

- Low maintenance costs compared to other engraving methods

- Long lifespan of the fiber laser source, reducing long-term costs

9️⃣ Is it easy to operate a 3D Fiber Laser Marking Machine?

Yes, the 3D Fiber Laser Marking Machine comes with user-friendly software that allows for easy setup and operation. The system often includes pre-programmed templates and the option to import CAD files for seamless design integration. Training is typically quick and straightforward, making it accessible for both beginners and experienced users.

🔟 What power options are available for the 3D Fiber Laser Marking Machine?

The 3D Fiber Laser Marking Machine is available in various power ranges to suit different applications, typically ranging from 20W to 100W. Higher power models are ideal for deep engraving or cutting harder materials, while lower power models are perfect for fine detail engraving on softer materials.

1️⃣1️⃣ Can I use the machine for both engraving and cutting?

Yes, the 3D Fiber Laser Marking Machine can both engrave and cut materials, depending on the power and settings. While it is primarily designed for engraving, higher-powered machines can also cut through thin metals, plastics, and other materials with precise edges.

1️⃣2️⃣ What are the maintenance requirements for the 3D Fiber Laser Marking Machine?

The 3D Fiber Laser Marking Machine requires minimal maintenance. Regular cleaning of the lens and checking the cooling system are essential. It’s important to maintain the machine’s laser module and focus lens for optimal performance. Additionally, ensuring the system is free from dust and debris will help keep the machine running smoothly.

1️⃣3️⃣ What types of software are compatible with the 3D Fiber Laser Marking Machine?

The 3D Fiber Laser Marking Machine typically supports various design software such as:

- CorelDRAW

- AutoCAD

- Adobe Illustrator

- LightBurn