Maszyna do grawerowania i cięcia laserowego CO2 z podwójnymi głowicami

Maszyna do grawerowania i cięcia laserowego CO2 z podwójną głowicą | Wysoka prędkość, precyzja podwójnej głowicy

„Zwiększ swoją wydajność i precyzję dzięki naszej nowoczesnej maszynie do grawerowania i cięcia laserowego CO2 z podwójną głowicą. Zaprojektowana z myślą o przemysłach o dużej wydajności, zapewnia szybszy czas przetwarzania bez utraty jakości.”

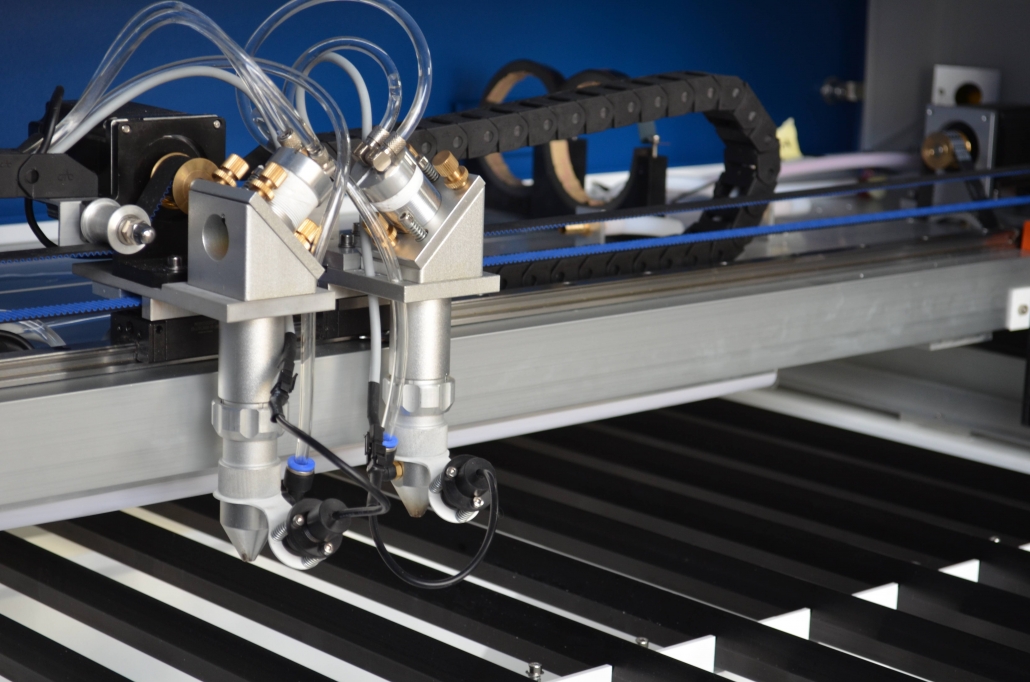

Maszyna do grawerowania i cięcia laserowego CO2 z podwójną głowicą posiada dwie niezależne głowice laserowe działające jednocześnie, co zwiększa wydajność i efektywność.

Oferuje precyzyjną kontrolę nad mocą i prędkością dla różnych materiałów, co czyni ją idealną do produkcji na dużą skalę.

Ta maszyna oszczędza miejsce i koszty w porównaniu do dwóch jednostek z pojedynczą głowicą i jest szeroko stosowana w przemyśle reklamowym, rzemieślniczym i produkcji oznakowań.

Różne rozmiary maszyny do grawerowania i cięcia laserowego CO2 z podwójnymi głowicami

Unlock Your Production Potential with the Double Head CO2 Laser Engraving Cutting Machine

Are you tired of slow production speeds? Struggling to get the precision you need for every project? Say goodbye to inefficiency and hello to faster, more accurate results. The Double Head CO2 Laser Engraving Cutting Machine is here to revolutionize your workflow.

1️⃣ Machine Features:

Double Head Laser Engraving Cutting Machine

Designed for non-metal materials, this machine uses dual heads working simultaneously, delivering double the efficiency and half the time.

Dual CO2 Glass Laser Tubes

Features two CO2 glass laser tubes with various power combinations:

- 80W + 80W,

- 100W + 100W,

- 150W + 150W,

- 180W + 180W,

- 80W + 150W,

- 80W + 180W.

Multiple Size Options

Choose between 130x90cm and 160x100cm working areas. Custom sizes can also be configured with double-head functionality.

Stepper Motor Drive System

Equipped with stepper motors, the machine achieves fast engraving speeds of up to 1200mm/sec, ensuring quick and efficient results.

Dual Heads for Enhanced Efficiency

The dual heads enable the machine to cut and engrave a variety of materials such as wood, acrylic, MDF, plastic, leather, and more.

Optional Functions

Enhance the machine with optional features like a red dot pointer, motorized up-down table, rotary attachment, auto focus, and WIFI, offering more convenience and expanded capabilities.

Enhanced Performance Features:

🔥 1.1 Double Head Operation

Boost your production speed like never before! With dual-head operation, both laser heads work simultaneously to cut and engrave. That means double the efficiency, half the time.

🎯 1.2 High Precision Cutting & Engraving

No more blurry edges or uneven cuts. Our machine delivers laser-sharp precision for all your designs, whether it’s intricate wood carvings, detailed acrylic engravings, or personalized leatherwork.

💡 1.3 Intelligent Control System

Imagine a system that learns and adapts. The smart control system automatically adjusts settings to optimize your cutting and engraving process—easy to use, seamlessly efficient, and reliable.

⏱️ 1.4 Save Time, Save Money

Get more done in less time. The dual heads working in unison will significantly reduce repetitive tasks, helping you save on labor costs and accelerate production timelines.

🛡️ 1.5 Built-in Safety Features

Safety first. Our machine is designed with your peace of mind in mind, featuring an advanced protection system to ensure you stay safe during operations.

2️⃣ Applications That Matter:

🌍 2.1 Industrial Manufacturing

Looking to ramp up your production? This machine is the perfect solution for high-volume production—whether you’re cutting, engraving, or both. Manufacturers love it for its speed and consistency.

🚀 2.2 Advertising Industry

Create eye-catching signage, billboards, and marketing materials in a fraction of the time. Perfect for designers who need high precision and fast turnarounds to stay competitive.

🎨 2.3 Crafting & Customization

Whether you’re designing personalized gifts, unique home decor, or fine art, the CO2 Laser Engraving Cutting Machine helps you bring your vision to life with remarkable detail and efficiency.

🏠 2.4 Home Decor & Personal Projects

From custom wooden signs to leather accessories, this machine is perfect for creating personalized, high-quality pieces that will make a statement in any home or business.

3️⃣ Technical Specifications:

Here’s a table summarizing the specifications for both the LM-1390 and LM-1610 double head CO2 laser engraving and cutting machines:

| Specification | SL-E1390 Double Heads | SL-E1610 Double Heads |

|---|---|---|

| Laser Type | CO2 glass laser tube, wavelength 10.6μm, water-cooled | CO2 glass laser tube, wavelength 10.6μm, water-cooled |

| Working Area | 1300 x 900 mm | 1600 x 1000 mm |

| Laser Power | 100W + 100W, 130W + 130W, 150W + 150W, 150W + 80W, 180W + 80W, 240W + 80W, 300W + 80W | 100W + 100W, 130W + 130W, 150W + 150W, 150W + 80W, 180W + 80W, 240W + 80W, 300W + 80W |

| Engraving Speed | 0-1200 mm/sec | 0-1200 mm/sec |

| Cutting Speed | 0-500 mm/sec | 0-500 mm/sec |

| Repeating Location Accuracy | ±0.01 mm | ±0.01 mm |

| Transmission Type | Belt transmission | Belt transmission |

| Driving System | Stepper motor | Stepper motor |

| Machine Table | Blade table (alternative: honeycomb table) | Blade table (alternative: honeycomb table) |

| Graphic Formats Supported | *.plt, *.dst, *.dxf, *.bmp, *.dwg, *.ai, *.las (supports AutoCAD and CorelDraw) | *.plt, *.dst, *.dxf, *.bmp, *.dwg, *.ai, *.las (supports AutoCAD and CorelDraw) |

| Software Supported | CorelDraw, AutoCAD | CorelDraw, AutoCAD |

| Control System | RuiDa RDC6445G DSP Off-line control system, laser power 0~100% adjustable | RuiDa RDC6445G |

1️⃣ Increased Efficiency and Productivity

The double-head design means you can complete two tasks simultaneously, drastically reducing production time. Whether you’re engraving or cutting, both laser heads work together to ensure faster turnarounds, boosting your overall productivity.

2️⃣ Maximized Precision

Thanks to the dual-head operation, precision is unmatched. Each laser head operates with laser-sharp accuracy, ensuring perfect results on every project. Whether it’s wood, acrylic, leather, or any other material, the machine guarantees flawless outcomes.

3️⃣ Cost and Time Savings

By cutting down the time it takes to complete a project, the double-head laser machine helps you save on labor costs and reduce operational expenses. More work done in less time means greater profitability for your business.

4️⃣ Enhanced Versatility

The double-head configuration offers unmatched flexibility. From large, complex projects to smaller, intricate designs, this machine handles a wide range of non-metal materials with ease, including wood, plastic, leather, acrylic, and MDF.

5️⃣ Streamlined Workflow

With dual lasers working in tandem, your workflow becomes more efficient. Fewer interruptions for reloading, changing settings, or switching materials means you can run continuous, uninterrupted operations, ensuring maximum output.

6️⃣ Customizable Power Options

The dual CO2 laser tubes offer various power configurations, giving you the flexibility to adjust based on the material and project size. Whether you need high power for thicker materials or lower power for detailed engravings, this machine can adapt to meet your needs.

7️⃣ Future-Proof Technology

As industries evolve and demand for high-precision engraving and cutting grows, the double-head laser machine is equipped with the latest CO2 laser technology, ensuring it can handle advanced applications for years to come.

8️⃣ User-Friendly Control System

The intelligent control system is designed for ease of use. Even beginners can operate the machine with confidence, as it automatically adjusts settings based on the material and task, allowing you to focus more on creativity and design.

1️⃣ What materials can the Double Head CO2 Laser Engraving Cutting Machine work with?

The machine is designed for non-metal materials, including wood, acrylic, MDF, plastic, leather, rubber, and paper. It is perfect for engraving and cutting materials used in crafting, manufacturing, and signage industries.

2️⃣ What is the difference between single-head and double-head laser machines?

The main difference lies in the dual-head operation. In a double-head laser machine, both heads work simultaneously, cutting and engraving at the same time. This effectively doubles the speed and efficiency compared to single-head machines, leading to higher productivity and faster turnaround times.

3️⃣ How fast can the machine engrave and cut?

The engraving speed can reach up to 1200mm/sec, depending on the material and design complexity. The cutting speed also varies based on material thickness and laser power, but the machine is optimized for high-speed operation, ensuring maximum workflow efficiency.

4️⃣ Can I adjust the power of the laser heads?

Yes, the machine offers multiple laser power configurations. You can select from combinations such as 80W+80W, 100W+100W, 150W+150W, 180W+180W, or mixed power options like 80W+150W and 80W+180W, giving you the flexibility to adjust based on your material and project needs.

5️⃣ What size options are available?

The machine comes in two standard sizes: 130x90cm and 160x100cm. Additionally, custom sizes can be configured to accommodate the double-head functionality, tailored to your specific project requirements.

6️⃣ Is the machine easy to operate?

Absolutely! The intelligent control system simplifies operation by automatically adjusting settings for optimal performance. The user interface is easy to navigate, making it accessible for both beginners and professionals.

7️⃣ How does the dual-head system improve efficiency?

The dual-head system allows both heads to work simultaneously, engraving and cutting on different parts of the material. This reduces setup times, minimizes downtime, and maximizes overall productivity, cutting processing time in half.

8️⃣ What optional features are available for this machine?

You can enhance the machine with several optional functions, including:

- Red dot pointer for precise positioning

- Motorized up-down table for adjusting material height

- Rotary attachment for engraving cylindrical objects

- Auto-focus for improved precision

- WIFI for remote control and monitoring

9️⃣ How do I maintain the machine?

Routine maintenance is simple. Keep the laser tubes clean, check the laser head alignment, and ensure the cooling system is functioning properly. Regular cleaning of the lens and mirrors will also help maintain optimal performance. The machine’s manual provides detailed maintenance instructions.

🔟 What warranty and support are offered?

The machine typically comes with a 1-year warranty, covering parts and labor. After the warranty period, support and parts are available. We also provide online support, technical assistance, and maintenance services to ensure your machine stays in top condition.

Więcej filmów z grawerowaniem i cięciem laserowym

Poproś o wycenę maszyny do grawerowania i cięcia laserowego CO2

SISMAR LASER oferuje maszyny do grawerowania i cięcia laserowego CO2 oraz inne rozwiązania dla wielu zastosowań przemysłowych. Nasze rozwiązania mogą stanowić ulepszenie dla istniejącego systemu grawerowania i cięcia laserowego CO2 lub doskonały wybór na pierwszą maszynę laserową.

Poproś o wycenę wysokiej jakości maszyny do grawerowania i cięcia laserowego CO2, która przekroczy Twoje oczekiwania. Możesz także umówić się na demonstrację, aby zobaczyć, jak działa maszyna do grawerowania i cięcia laserowego CO2.

Witamy w SISMAR Laser. Bardzo chętnie odpowiemy na wszelkie pytania dotyczące naszych maszyn do znakowania i cięcia laserowego włókna.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- EZCAD common errorMarch 18, 2025 - 2:09 am

- Small Business Guide: Navigating the Evolving 3D Crystal Engraving Market in 2025March 12, 2025 - 5:31 am

- “Continuous vs. Pulsed Laser Cleaning: Single Mode vs. Multi Mode LasersFebruary 21, 2025 - 5:54 am

- “Laser precision, zero damage—cleaning rust and paint without harming your product.”February 21, 2025 - 3:08 am

- Why Choose glass laser drilling machineJanuary 31, 2025 - 4:59 am