200W 300W Pulsed fiber laser cleaing machine

Safe, Chemical-Free Cleaning for Complex and Delicate Surfaces

Pulsed Fiber Laser Cleaning Machine – Precision, Safety, and Efficiency

Our Pulsed Fiber Laser Cleaning Machine, available in 100W, 200W, and 300W models, uses advanced pulsed laser technology to remove rust, paint, oil, coatings, and contaminants from both metal and non-metal surfaces. Unlike continuous laser systems, it delivers controlled bursts of energy, preventing surface damage and ensuring zero harm to the material.

With its compact, portable, and handheld design, this laser cleaner is easy to move and operate in various settings. It’s perfect for industries requiring high-precision cleaning without chemicals or abrasives, providing eco-friendly, fast, and efficient results.

Whether you’re in need of rust removal or surface restoration, our Laser Rust Remover helps you maintain product quality while driving business growth.

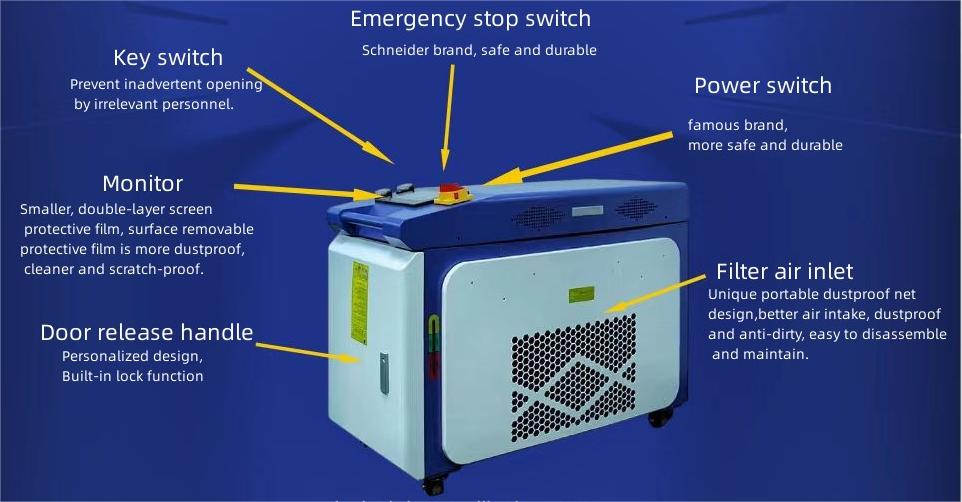

Machine Photos of pulsed laser cleaning machine

SISMAR LASER Pulsed Fiber Laser Cleaning Machine: Precision, No Damage, and Superior Cleaning Solution

In industrial production, surface cleanliness is not just a matter of appearance—it directly impacts product quality and longevity. Traditional cleaning methods often force you to choose between effectiveness and risk: chemical cleaning leads to pollution, while mechanical cleaning can damage delicate surfaces. So, when dealing with stubborn rust or paint removal, have you ever struggled to find a solution that ensures both effectiveness and safety?

SISMAR LASER Pulsed Fiber Laser Cleaning Machine is here to solve your problems.

1.Pain Points:

- You need to remove tough paint and rust but fear damaging the precision components or underlying colors.

- You need cleaning without leaving a trace, especially on intricate parts where even the slightest scratch or damage can affect performance.

- Traditional methods using chemicals or high-pressure could leave secondary contamination or increase post-cleaning costs.

2.Solution:

The SISMAR LASER Pulsed Fiber Laser Cleaning Machine uses high-efficiency pulsed laser beams to precisely remove surface contaminants, including paint, rust, and debris, without the need for chemicals or physical contact. By emitting short, intense laser pulses, it vaporizes contaminants instantly, leaving the base color intact and cleaning with precision. Each cleaning session feels like a delicate restoration of the product’s surface, not a harsh grind. Perfect for high-precision components, electronics, and even artwork.

With SISMAR LASER Pulsed Fiber Laser Cleaning Technology, you can:

| # | Feature | Description |

|---|---|---|

| 1 | Remove Contaminants Completely | Even the toughest rust and paint are no match. |

| 2 | Preserve the Surface Integrity | Precise control of laser energy ensures no damage to the base color or delicate craftsmanship. |

| 3 | Be Efficient and Eco-Friendly | No chemicals, no high-pressure water—avoiding pollution and additional post-treatment costs. |

| 4 | Enjoy Versatile Applications | Whether it’s steel, aluminum alloys, electronic components, or artwork, SISMAR LASER offers the perfect solution. |

Don’t let traditional cleaning methods limit you. Choose the SISMAR LASER Pulsed Fiber Laser Cleaning Machine and let every detail shine with precision, quality, and efficiency.

What you’re after is more than just cleanliness—it’s perfection without compromise. Experience SISMAR LASER Pulsed Fiber Laser Cleaning Machine today, and make cleaning more efficient, precise, and eco-friendly.

3.Parameter of Pulsed laser cleaning machine

Handheld Laser Rust Remover Parameters | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | SL-C200/300 | |||||||||||

| Laser power | 200W/300W | |||||||||||

| Working Voltage | 110/220V 50/60 HZ | |||||||||||

| Laser Working Mode | Pulse | |||||||||||

| Laser Source | JPT | |||||||||||

| Average Laser Power | >300W | |||||||||||

| Power Instability | <5% | |||||||||||

| Maximum Pulse Energy | 15mJ | |||||||||||

| Pulse Width | 2-500ns | |||||||||||

| Cooling Method | Water Cooling | |||||||||||

| Power Regulation Range(%) | 0-100( Gradient Adjustable) | |||||||||||

| Repeat Frequency(kHz) | 1-4000(Gradient Adjustable) | |||||||||||

| Fiber Cable Length | 5m | |||||||||||

| Cleaning Head Weight (including isolator) | <1.5Kg | |||||||||||

| Working Environment Humidity | ≤80% | |||||||||||

| Working Environment Temperature | 10℃~40℃ | |||||||||||

| Machine Dimensions (Length, width and height) | About 860mm*410mm*700mm | |||||||||||

| Machine Weight | About 80Kg | |||||||||||

Laser Cleaning Head Parameters | ||||||||||||

| Cleaning Head Weight | Less Than 1.25Kg | |||||||||||

| Scanning Width | 0-145mm Optional | |||||||||||

| Scanning Frequency | Not Less Than 300Hz | |||||||||||

| Maximum Scan Line Speed | About 30m/s | |||||||||||

| Maximum Scanning Speed | 20000mm/s | |||||||||||

| Light Transmittance | ≥98% | |||||||||||

| Laser Power Adjustment | 10%-100% | |||||||||||

| Focal Length | Standard configuration 210mm (160mm/254mm/330mm/420mm optional) | |||||||||||

| Incident Spot Diameter | ≤10mm | |||||||||||

| Cable Length | Standard configuration of 10m | |||||||||||

🚀 1️⃣ Why Pulsed Fiber Laser Cleaning Machine is the Future of Surface Cleaning

Are you tired of cleaning methods that are too harsh on your equipment or just don’t deliver the results you need? Traditional cleaning methods—like chemicals, abrasives, or high-pressure washing—can damage your products and lead to costly repairs. If you need an effective, eco-friendly, and precise solution, look no further than the Pulsed Fiber Laser Cleaning Machine.

This cutting-edge technology is revolutionizing the way industries clean their surfaces. From rust removal to coating removal, pulsed fiber laser cleaning offers a safe, efficient, and environmentally friendly approach to cleaning a variety of materials. Let’s dive into how this powerful machine can benefit key industries.

✨ 2️⃣ Key Applications of Pulsed Fiber Laser Cleaning Machine

⚙️ 2.1 Rust and Oxidation Removal in the Metal Industry

Rust and oxidation are a common problem in industries that deal with metal components. Pulsed fiber laser cleaning quickly removes corrosion without damaging the underlying surface, ensuring that your materials stay intact and ready for use. This is especially important for automotive manufacturing, construction, and metal fabrication, where high-quality materials are essential.

Benefits:

- Fast, efficient rust removal

- Preserves material integrity

- No chemicals or abrasive materials involved

⚡ 2.2 Paint and Coating Removal in the Automotive and Aerospace Industries

The Pulsed Fiber Laser Cleaning Machine is ideal for removing paint, coatings, and adhesives without harming delicate surfaces. In industries like automotive manufacturing and aerospace, precise paint removal is necessary to prepare parts for refinishing or further processing.

Benefits:

- Removes paint and coatings with laser precision

- No risk of damaging intricate parts

- Eco-friendly solution, no harmful chemicals

💻 2.3 Surface Preparation for Electronics

When it comes to cleaning electronic components, such as circuit boards or delicate parts, the Pulsed Fiber Laser Cleaning Machine offers a non-contact solution. The laser’s ability to clean without physical touch ensures sensitive components are not damaged, making it perfect for the electronics manufacturing industry.

Benefits:

- Non-contact, preserving delicate components

- Precise cleaning without damage

- Ideal for small, complex surfaces

🔧 2.4 Mold and Die Cleaning in Manufacturing

For industries involved in plastic molding or metal casting, keeping molds and dies free from contaminants is crucial. The Pulsed Fiber Laser Cleaning Machine easily removes build-up of rubber, metal, or plastic residue without wear and tear, extending the life of your molds and dies.

Benefits:

- Removes contaminants quickly and effectively

- No abrasive materials, preserving mold quality

- Increases efficiency by reducing downtime

🏺 2.5 Historical Artifact Restoration in Museums and Art Conservation

The gentle yet effective nature of Pulsed Fiber Laser Cleaning makes it the perfect solution for cleaning delicate historical artifacts. Whether it’s removing soot from sculptures or rust from metal objects, this technology helps preserve and restore items in art conservation and museum restoration.

Benefits:

- Safe for delicate, priceless items

- Gentle cleaning process maintains historical value

- Eco-friendly, no chemicals used

🔥 3️⃣ Why Choose Pulsed Fiber Laser Cleaning?

The Pulsed Fiber Laser Cleaning Machine isn’t just another cleaning tool—it’s a game changer. Unlike traditional methods, it offers several unbeatable advantages:

- Precision: Laser cleaning ensures every surface is treated exactly as it needs to be, without damaging the underlying material.

- Efficiency: You can remove rust, coatings, and contaminants faster than ever before.

- Eco-Friendly: No need for harsh chemicals or solvents, making it an environmentally conscious choice.

- Cost-Effective: It reduces the need for manual labor, abrasive tools, and expensive chemicals, saving you money in the long run.

💡 4️⃣ Take Your Cleaning Process to the Next Level

Whether you’re in metal manufacturing, automotive production, or electronics, the Pulsed Fiber Laser Cleaning Machine offers an advanced, reliable, and eco-friendly solution to your cleaning needs. By eliminating the problems of traditional methods and offering precision and efficiency, this machine is set to transform the way industries approach surface cleaning.

Ready to experience the future of cleaning? Choose the Pulsed Fiber Laser Cleaning Machine and ensure your equipment stays in top shape, with minimal environmental impact and maximum efficiency.

FAQ – Pulsed Fiber Laser Cleaning Machine

1. How does the Pulsed Fiber Laser Cleaning Machine work?

Answer:

The Pulsed Fiber Laser Cleaning Machine uses short, high-energy laser pulses to interact intensely with the surface contaminants like rust, paint, and oxides. The laser energy causes these contaminants to evaporate or fragment almost instantly. This non-contact cleaning method effectively removes surface dirt without damaging the base material. Laser cleaning is not only fast and efficient but also free from chemical pollutants.

2. How often does the Pulsed Fiber Laser Cleaning Machine need maintenance?

Answer:

Typically, the maintenance cycle for a Pulsed Fiber Laser Cleaning Machine is every 6 months to 1 year. The exact maintenance schedule depends on usage frequency and environmental conditions. Routine maintenance includes checking the fiber optic cables, laser source, cooling system, and control systems to ensure proper functioning. It’s recommended to regularly clean the machine’s interior and keep the laser output port clean for optimal performance.

3. What types of materials are suitable for cleaning with a Pulsed Fiber Laser Cleaning Machine?

Answer:

The Pulsed Fiber Laser Cleaning Machine is suitable for a wide range of materials, especially metals. Common materials include:

- Steel, aluminum alloys, copper, etc.: Removing rust, paint, oxides, and more.

- Plastics and rubber: Cleaning surface contaminants or old coatings.

- Precision electronic components: Non-contact cleaning to avoid damage to delicate structures.

- Art and historical artifacts: Gentle cleaning to remove surface dirt while preserving the original appearance.

4. What impact does laser cleaning have on surfaces?

Answer:

The Pulsed Fiber Laser Cleaning Machine has minimal impact on surfaces. Since the cleaning process is non-contact, it doesn’t cause physical abrasion or scratching. By precisely controlling the laser pulses and power, the cleaning action targets only the contaminants without damaging the underlying material, making it ideal for delicate and high-precision cleaning tasks.

5. Is laser cleaning environmentally friendly?

Answer:

Yes, Pulsed Fiber Laser Cleaning is an environmentally friendly method. Unlike traditional chemical cleaning or high-pressure washing, laser cleaning doesn’t require any chemical solvents, and it doesn’t generate harmful waste or pollutants. It reduces the use of chemicals and prevents secondary pollution, aligning with modern eco-friendly standards.

6. Is laser cleaning effective for all types of contaminants?

Answer:

The Pulsed Fiber Laser Cleaning Machine is highly effective in removing a variety of contaminants, including rust, paint, oxides, dirt, adhesives, and other industrial residues. However, some stubborn contaminants (like deeply embedded substances) may require multiple cleaning sessions. Laser power and frequency can be adjusted depending on the cleaning task to optimize results.

7. Is the operation of the Pulsed Fiber Laser Cleaning Machine complex?

Answer:

No, operating the Pulsed Fiber Laser Cleaning Machine is simple and intuitive. Users can control the machine through a touchscreen or computer software. The cleaning process can be performed in automatic mode, reducing the need for specialized skills. Most laser cleaning machines also come with safety features to ensure safe operation throughout the cleaning process.

8. How fast is the cleaning speed of the Pulsed Fiber Laser Cleaning Machine?

Answer:

The cleaning speed of the Pulsed Fiber Laser Cleaning Machine is incredibly fast, typically capable of cleaning several square meters per minute, depending on the type of contaminants and the surface condition. For light contamination, the cleaning speed is faster; for more stubborn stains, it might take a little longer, but laser cleaning still remains much more efficient compared to traditional methods.

9. Does laser cleaning require a special operating environment?

Answer:

The Pulsed Fiber Laser Cleaning Machine is adaptable, but to ensure optimal performance, it is best used in a well-ventilated environment with moderate temperature. Avoid extreme humidity or high temperatures. Most machines are equipped with cooling systems to maintain the device within a suitable operating temperature range.

10. What is the lifespan of the Pulsed Fiber Laser Cleaning Machine?

Answer:

The Pulsed Fiber Laser Cleaning Machine typically lasts over 10 years. The lifespan depends on factors like usage frequency, environmental conditions, and regular maintenance. With proper care and timely repairs, the laser cleaning machine can maintain its high efficiency and continue to provide reliable cleaning service for businesses over the long term.

These FAQs are designed to help you better understand the Pulsed Fiber Laser Cleaning Machine, its benefits, and how it can enhance your cleaning process. Whether you’re in the automotive, manufacturing, or electronics industries, this machine offers a high-performance, eco-friendly solution for your cleaning needs.

Working Video of Pulsed Laser Cleaning Machine

Request a Quote for a Laser cleaning Machine

SISMAR LASER has Laser Cleaning Machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser cleaning system or an excellent choice for your first laser machine.

Request a quote for a high-quality laser cleaning that exceeds your expectations. You can also schedule a demo to see how green laser cleaning works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting/welding machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- EZCAD common errorMarch 18, 2025 - 2:09 am

- Small Business Guide: Navigating the Evolving 3D Crystal Engraving Market in 2025March 12, 2025 - 5:31 am

- “Continuous vs. Pulsed Laser Cleaning: Single Mode vs. Multi Mode LasersFebruary 21, 2025 - 5:54 am

- “Laser precision, zero damage—cleaning rust and paint without harming your product.”February 21, 2025 - 3:08 am

- Why Choose glass laser drilling machineJanuary 31, 2025 - 4:59 am