Green Laser Marking Machine – Precision and Versatility

Unlock Exceptional Marking Quality with Green Laser Technology

Elevate Your Marking with the Green Laser Marking Machine 🌟

Looking for precision without damaging delicate materials? The Green Laser Marking Machine is your solution!

🌿 Why Green Laser?

- High Precision: Perfect for intricate designs on plastics, glass, and metals with its 532 nm wavelength.

- No Damage: The low thermal energy avoids burns or melting, ensuring clean, sharp marks.

- Versatile Use: Ideal for industries like electronics, medical, automotive, and aerospace.

🔥 Key Benefits:

- Flawless Marking on reflective surfaces.

- Eco-Friendly with low energy consumption.

- Long-lasting durability with minimal maintenance.

Ready to boost your business? Let the Green Laser Marking Machine work its magic!

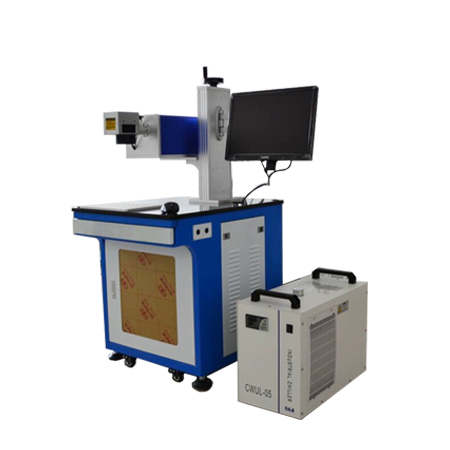

Photos of Flying Laser Marking machine

🌟 Green Laser Marking Machine: Precision, Speed, and Sustainability 🌟

Transform your business with cutting-edge green laser technology that delivers exceptional precision and powerful performance. Whether you’re marking metal, plastic, glass, or ceramics, this machine brings you superior results with unmatched accuracy – all while being energy-efficient and eco-friendly.

Why Choose the Green Laser Marking Machine?

💎 Incredible Precision

Achieve ultra-fine markings on even the most intricate designs. Perfect for small text, barcodes, QR codes, and detailed logos.🌍 Versatile Material Compatibility

This machine works wonders on metals, plastics, ceramics, and glass, making it your go-to solution for a wide range of applications.🌱 Eco-Friendly Efficiency

With a low-power, green laser, you get high-speed marking with minimal energy consumption – saving you both time and money, while reducing your carbon footprint.🛠️ Long-Term Durability

Built to last, this machine requires minimal maintenance, meaning you get reliable performance and consistent results for years to come.💚 Sustainable Technology

The green laser wavelength is gentler on the environment and safer for the eyes, making it an ideal choice for businesses committed to sustainability.

Key Features

🎯 Precision at its Best

Whether you’re marking fine text or complex logos, the green laser provides unparalleled precision that ensures your marks are crisp, clear, and high-contrast.🔧 Superb Versatility

This machine is perfect for a variety of materials, including:- Metal

- Plastic

- Ceramics

- Glass

- And more…

⚡ Speed and Power

Experience fast marking speeds with low power consumption, allowing you to increase productivity and lower operational costs at the same time.🛡️ Durable and Low Maintenance

Designed for high-volume use, this machine offers long-lasting performance with low upkeep, ensuring consistent quality with minimal downtime.🌿 Eco-Friendly Technology

The green laser wavelength is safer for both your team and the planet, ensuring sustainable operations without compromising on power or efficiency.

🚀 Ready to Take Your Marking to the Next Level?

Don’t settle for ordinary. With the Green Laser Marking Machine, you get cutting-edge technology, impressive performance, and eco-friendly benefits all in one package. Ready to boost your production quality and efficiency? Contact us now to learn more or request a demo!

| Wavelength | 532 nm |

| Marking Speed | 250 characters per second |

| Beam Quality M2 | < 1.2 |

| Mark the Minimum Line Width | 30μm-50μm |

| Laser Power | 10, 15, 20 W |

| Marking Field Size | 100mm*100mm |

| The Standard Lens | F160 |

| Laser Safety Level | Class I |

| Electrical Connection | 220V /15A, 50/60 Hz |

| Power Consumed | 1.5 Kw – 2.0 Kw |

| Dimensions | 800mm*950mm*1630mm; |

| Warranty Coverage | 1-year |

Applications of a Flying Laser Marking Machine:

The versatility of a Flying Laser Marking Machine makes it a highly sought-after solution in a variety of industries. Whether you’re working with complex materials or need high-speed, high-quality marks, this technology can significantly improve your production efficiency and product quality. Here’s a look at some key applications:

Automotive Industry

Key Application: Marking vehicle identification numbers (VINs), part numbers, and logos.

Why it Works: Automotive parts need to be marked quickly and precisely to meet regulatory requirements. The flying laser marking machine allows for continuous marking on moving parts, such as engine blocks, tires, and electrical components, without interrupting the manufacturing process.

Case Example: A leading car manufacturer used the system to mark VIN numbers on various parts during assembly. The flying laser technology ensured that marks were clear, precise, and durable, even in high-speed production environments.Electronics and Semiconductor Industry

Key Application: Marking serial numbers, QR codes, and product logos on circuit boards, chips, and other delicate components.

Why it Works: The precision of the flying laser ensures that even tiny parts can be marked without causing damage. It’s ideal for marking on materials like PCBs, which are sensitive to mechanical pressure.

Case Example: A semiconductor company utilized a flying laser marking machine to engrave batch codes on microchips. The laser’s non-contact process ensured the chips weren’t damaged while maintaining clear, legible markings that met quality control standards.Medical Devices

Key Application: Marking serial numbers, barcodes, and regulatory symbols on surgical instruments, implants, and other medical equipment.

Why it Works: In the medical field, traceability and sterilization are critical. The flying laser marking machine provides clean, durable, and tamper-resistant markings, essential for regulatory compliance.

Case Example: A manufacturer of surgical instruments adopted flying laser marking for engraving serial numbers on stainless steel tools. This ensured that each tool could be traced and tracked throughout its lifecycle without affecting its integrity.Packaging and Food Industry

Key Application: Marking expiration dates, batch numbers, and other product information on packaging materials, bottles, and containers.

Why it Works: The flying laser system allows for high-speed, continuous marking of packaging materials, ensuring that products are accurately labeled and ready for sale. It works across various materials, including glass, plastic, and cardboard.

Case Example: A food packaging company used the flying laser marking machine to print expiration dates on containers at a rapid pace. The system’s speed and accuracy ensured no interruptions in the high-volume production line.Jewelry and Luxury Goods

Key Application: Engraving logos, serial numbers, and intricate designs on rings, watches, and accessories.

Why it Works: Laser marking offers the precision necessary to engrave fine details on delicate items like jewelry. This non-contact process ensures the pieces remain unscathed while maintaining a high level of detail.

Case Example: A luxury jewelry brand used the flying laser marking machine to engrave unique codes and logos on their pieces. The result was high-quality, permanent markings that were both aesthetically pleasing and secure, helping the brand fight counterfeiting.Aerospace Industry

Key Application: Marking serial numbers, part numbers, and safety-critical data on metal and composite parts.

Why it Works: Aerospace components often require precise and durable markings for identification and safety compliance. The flying laser marking machine ensures that marks can withstand harsh conditions like heat, moisture, and vibrations.

Case Example: A supplier of aerospace components used flying laser marking for engraving batch codes and part numbers on titanium components. The laser ensured that each part could be tracked through rigorous safety inspections and regulations.Consumer Electronics

Key Application: Marking logos, serial numbers, and product information on electronic gadgets and accessories.

Why it Works: The flying laser marking machine can operate at high speeds and is ideal for marking plastic or metal surfaces on products like smartphones, laptops, and headphones.

Case Example: A consumer electronics manufacturer used the flying laser marking system to engrave serial numbers on smartphones. This ensured easy tracking of each device during manufacturing and helped prevent counterfeit products from entering the market.Tool and Hardware Industry

Key Application: Marking logos, model numbers, and batch information on tools, equipment, and hardware products.

Why it Works: Tools and hardware need clear, durable markings to identify the product and provide essential data to users. The flying laser marking machine provides these markings without affecting the surface finish or functionality.

Case Example: A manufacturer of power tools used flying laser marking to engrave model numbers and safety instructions on metal components. The result was clear, permanent markings that remained intact even after extended use.

In Summary:

Flying laser marking machines are incredibly versatile and can be applied across a wide range of industries. Whether you’re in automotive, electronics, medical devices, or luxury goods, this technology can help you achieve high-speed, high-precision marking that enhances your product’s traceability, compliance, and brand identity. It’s the solution you need for continuous, non-contact, and environmentally friendly marking.

Frequently Asked Questions (FAQ) – Green Laser Marking Machine

1️⃣ What is a Green Laser Marking Machine?

A Green Laser Marking Machine uses a 532nm green laser wavelength, specifically designed to mark and engrave materials like gold, silver, copper, plastics, and more. This technology provides high precision and clean marks, making it ideal for industries such as jewelry engraving, electronics, and luxury goods.

2️⃣ What materials can the Green Laser Marking Machine be used on?

The Green Laser Marking Machine excels in marking and engraving on a variety of materials, particularly those that are highly reflective. These include:

- Metals: Copper, gold, silver, stainless steel, aluminum.

- Jewelry: Ideal for engraving intricate designs on precious metals.

- Plastics: Works on certain plastics used in electronics and consumer products.

- Ceramics: Suitable for marking ceramic surfaces.

- Coated Materials: Great for anodized aluminum, painted surfaces, and more.

3️⃣ What industries benefit from using a Green Laser Marking Machine?

- Jewelry Industry: Perfect for engraving delicate luxury items, such as rings, necklaces, and watches.

- Electronics: Used for marking PCBs, semiconductors, and small components.

- Luxury Goods: Engraves logos, serial numbers, and branding on high-end items.

- Automotive & Aerospace: Marks metal parts with precision for traceability and identification.

- Medical Devices: Ensures traceability and certification for medical equipment.

4️⃣ What is the difference between a Green Laser Marking Machine and other laser machines?

Unlike fiber laser or CO2 laser machines, the Green Laser Marking Machine uses a 532nm green wavelength, which makes it more effective for reflective metals like gold and silver. It is ideal for applications requiring high contrast, fine detail, and high precision on luxury items or small components.

5️⃣ What is the marking speed of the Green Laser Marking Machine?

The typical marking speed of the Green Laser Marking Machine ranges from 1000 mm/s to 8000 mm/s. This varies depending on the material, complexity of the design, and the laser power. For detailed designs or engraving on hard materials, the speed may be slower to achieve the best results.

6️⃣ How deep can the Green Laser Marking Machine engrave?

The depth of engraving largely depends on the material and laser power. Generally, the Green Laser Marking Machine is suitable for surface engraving or shallow engraving. For deeper engravings or cutting thicker materials, higher-powered fiber lasers may be more suitable.

7️⃣ What are the advantages of using a Green Laser Marking Machine?

- High Precision: Ideal for fine details and intricate designs.

- Effective on Reflective Metals: Superior at marking gold, silver, and copper.

- Permanent Marks: Produces high-contrast, durable marks that last.

- Clean Engraving: Ensures sharp, clean edges without burning or discoloration.

- Eco-Friendly: Low power consumption and no consumables (ink or chemicals).

8️⃣ Can the Green Laser Marking Machine be used for cutting?

While the Green Laser Marking Machine is primarily designed for engraving, it can be used for cutting thin metals, plastics, and other materials in specific cases. However, for thicker materials or heavy-duty cutting, a fiber laser with higher power would be more effective.

9️⃣ Is the Green Laser Marking Machine easy to operate?

Yes, the Green Laser Marking Machine is designed for ease of use. With an intuitive interface and simple software, you can quickly upload designs, adjust settings, and start marking. Even if you’re new to laser technology, you’ll find it user-friendly and easy to get started with.

🔟 How long does the Green Laser Marking Machine last?

The laser source of the Green Laser Marking Machine can last up to 50,000 hours, making it a durable investment. Regular maintenance like cleaning the lenses, replacing filters, and updating the software will help extend the lifespan and ensure consistent performance.

1️⃣1️⃣ How much does a Green Laser Marking Machine cost?

The price of a Green Laser Marking Machine can range from $15,000 to $45,000, depending on factors like laser power, marking area, and features. It’s a good investment for businesses that require high-precision engraving and marking on high-value materials like jewelry, luxury goods, and electronics.

1️⃣2️⃣ What maintenance is required for the Green Laser Marking Machine?

Routine maintenance for the Green Laser Marking Machine includes:

- Cleaning the lens and mirrors to maintain optimal performance.

- Checking the air filter and replacing it as needed.

- Regular software updates to ensure smooth operation.

- Ensuring the cooling system is functioning properly.

These tasks are simple and usually do not require professional help.

1️⃣3️⃣ Can the Green Laser Marking Machine handle large-scale production?

Yes, the Green Laser Marking Machine is designed for both low and high-volume production. Its fast marking speeds, coupled with its durability and low maintenance, make it suitable for industries that require large-scale, high-precision marking, such as electronics manufacturing and luxury goods engraving.

Request a Quote for a Green Laser Marking Machine

SISMAR LASER has green laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- EZCAD common errorMarch 18, 2025 - 2:09 am

- Small Business Guide: Navigating the Evolving 3D Crystal Engraving Market in 2025March 12, 2025 - 5:31 am

- “Continuous vs. Pulsed Laser Cleaning: Single Mode vs. Multi Mode LasersFebruary 21, 2025 - 5:54 am

- “Laser precision, zero damage—cleaning rust and paint without harming your product.”February 21, 2025 - 3:08 am

- Why Choose glass laser drilling machineJanuary 31, 2025 - 4:59 am