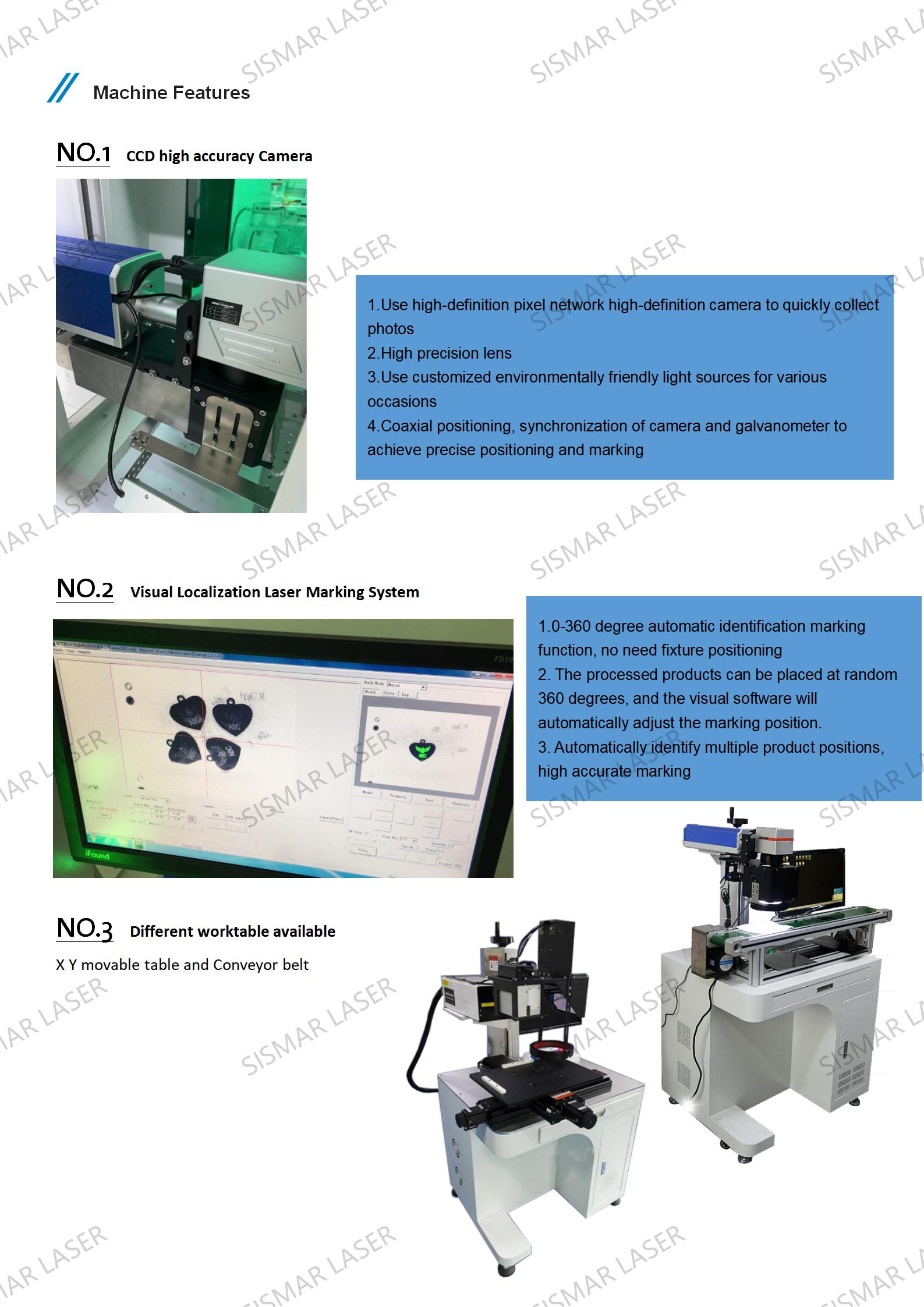

CCD Visual Position Laser Marking Machine

Visual Localization Laser Marking Machine

The Visual Position Laser Marking Machine, also known as the CCD Laser Marking Machine.

It offers high-precision, automated marking without the need for fixtures.

✅ Smart CCD Positioning – Auto-detects part position & angle for perfect alignment.

✅ 0.01mm Ultra-Precision – Ideal for small, irregular, and high-detail marking.

✅ Cost & Time Efficient – Eliminates fixtures, reducing costs & boosting productivity.

Perfect for industries needing fast, accurate, and automated laser marking on small or irregular parts.

CCD visual Position Laser Marking Machine Photo

Revolutionize Your Marking Process with the CCD Visual Position Laser Marking Machine

Tired of manual positioning, expensive fixtures, and inconsistent results? The CCD Visual Position Laser Marking Machine is the game-changer you need! Powered by an intelligent CCD vision system, it automatically detects and adjusts to the shape, size, and angle of each part—delivering flawless, ultra-precise laser marking every time.

🚀 Why Choose the CCD Visual Position Laser Marking Machine?

🔥 No More Fixtures!

Forget about costly jigs and fixtures. Unlike traditional laser marking machines that require manual part placement, the CCD camera system instantly locates each workpiece, eliminating setup hassles and saving time & money.

🎯 Precision Like Never Before – 0.01mm Accuracy!

Traditional machines rely on human alignment, leading to errors and wasted materials. The CCD Visual Position Laser Marking Machine ensures pinpoint accuracy—perfect for small, intricate, or high-volume parts.

⚡ Faster Production, Higher Profits

While conventional laser markers require manual adjustments for each item, the CCD vision system works instantly—marking irregular, complex, or even overlapping parts without missing a beat. That means higher efficiency, faster output, and more revenue for your business!

💎 Perfect for Small & Irregular Parts

Ideal for jewelry, electronics, medical tools, auto parts, and precision components, this machine excels where others fail—handling tiny, uneven, or varying shapes with zero positioning errors.

🔄 Smart Automation = Less Labor Costs

No need for skilled operators! The CCD system does the work, reducing labor costs and minimizing human error. Just place the parts on the work area, and the machine does the rest!

Upgrade to the Future of Laser Marking!

Ditch the old-school, time-consuming methods and switch to the CCD Visual Position Laser Marking Machine—where speed, precision, and automation take your business to the next level.

👉 Contact us today to see how this cutting-edge technology can transform your production!

CCD Visual Position Laser Marking Machine – Technical Specifications

| Parameter | Details |

|---|---|

| Laser Type | Fiber Laser (Raycus/JPT) |

| Laser Power Options | 20W / 30W / 50W / 60W / 80W / 100W |

| Laser Wavelength | 1064nm |

| Marking Area | 110×110mm / 150×150mm / 175×175mm / 200×200mm (Customizable) |

| CCD Vision System | High-Precision Industrial Camera |

| Positioning Accuracy | ±0.01mm |

| Marking Speed | ≤7000mm/s |

| Minimum Line Width | 0.01mm |

| Minimum Character Size | 0.15mm |

| Repetition Accuracy | ±0.002mm |

| Cooling Method | Air Cooling |

| Laser Lifespan | ≥100,000 Hours |

| Supported Formats | PLT, DXF, AI, BMP, JPG, PNG, SVG, etc. |

| Compatible Software | EZCAD 2.0 / 3.0 |

| Connectivity | USB |

| Power Supply | AC110V/220V ±10%, 50/60Hz |

| Machine Dimensions | Varies by model |

| Weight | Varies by model |

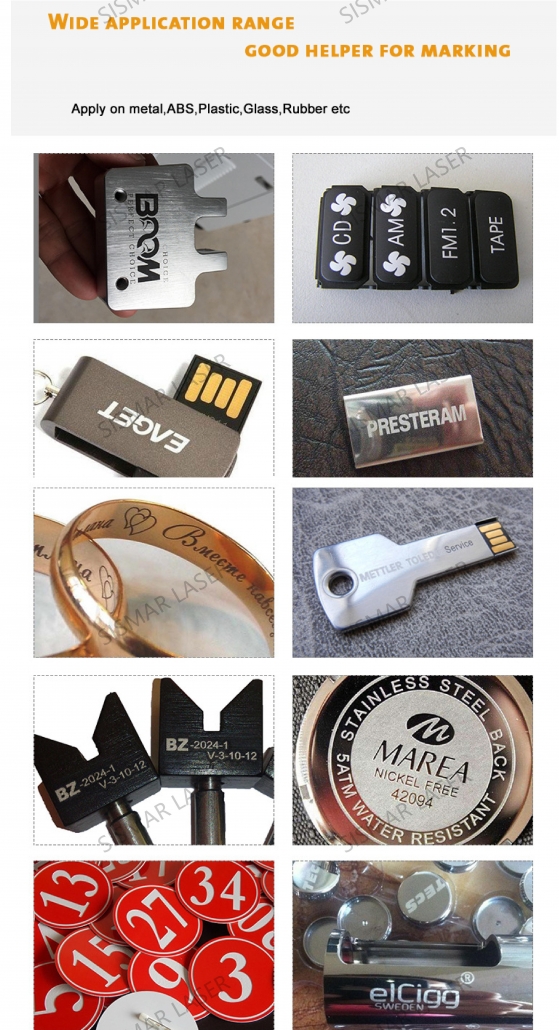

Applications of CCD Visual Position Laser Marking Machine – High-Precision Marking for Every Industry

The CCD Visual Position Laser Marking Machine is revolutionizing the way industries approach high-precision laser marking. Equipped with an intelligent CCD vision system, it offers seamless, accurate marking on even the most irregular and small parts—a must-have for businesses in jewelry, electronics, medical devices, automotive, and precision engineering.

💎 Jewelry Industry – Precision Engraving & Cutting

In the jewelry industry, the CCD Visual Position Laser Marking Machine excels in delivering fine, intricate markings with unmatched accuracy and speed.

🔹 Gold & Silver Jewelry – Effortlessly engrave names, logos, and custom designs on rings, necklaces, and pendants.

🔹 Hallmarking & Quality Stamps – Apply regulatory marks and brand logos with perfect precision.

🔹 Micro-Engraving – Engrave detailed patterns, serial numbers, and personalized messages on small jewelry pieces.

Why it’s perfect for jewelry? The CCD visual system eliminates manual adjustments, ensuring flawless results every time.

🔩 Electronics & Semiconductor – Fast & Accurate Component Marking

In the electronics industry, precision is paramount, and the CCD Visual Position Laser Marking Machine is up to the task.

🔹 PCBs & Circuit Boards – Mark QR codes, serial numbers, and component labels with ultra-precision.

🔹 Microchips & ICs – Perfect for tiny, intricate components, ensuring clear identification on minuscule surfaces.

🔹 Casings & Components – Mark trademarks, batch numbers, and tracability data on electronic products.

Why choose it? The CCD system ensures quick, automated marking without costly fixturing or manual labor, speeding up production.

🏥 Medical Devices – Sterile, Permanent Marking

For the medical industry, ensuring precise, permanent markings on surgical tools and devices is crucial.

🔹 Surgical Instruments – Etch serial numbers, safety marks, and brand logos on scalpels, forceps, and more.

🔹 Implants & Prosthetics – Engrave implant identifiers, serial numbers, and UDI codes on titanium and stainless steel.

🔹 Medical Device Labels – Permanently mark UDI codes, batch numbers, and manufacturing dates on devices.

Why it’s ideal? Permanent, non-fading laser marks guarantee sterile, safe, and traceable medical instruments.

🚗 Automotive & Aerospace – Reliable Traceability for Critical Components

For automotive and aerospace industries, the CCD Visual Position Laser Marking Machine is an invaluable tool in marking critical parts.

🔹 Engine Components – Mark VIN numbers, serial numbers, and production data with exceptional accuracy.

🔹 Metal Parts & Tools – Apply compliance marks, barcodes, and part numbers on high-stress automotive components.

🔹 Safety & Regulatory Labels – Engrave warning symbols and regulatory marks on parts.

Why is it a game-changer? The vision system allows fast, error-free positioning, even on the smallest components, improving traceability and safety.

⚙ Hardware & Precision Tools – Marking for Heavy-Duty Use

From industrial tools to hardware components, the CCD Visual Position Laser Marking Machine provides fast, permanent marking for businesses needing high-quality, durable markings.

🔹 Cutting Tools & Blades – Perfect for engraving part numbers and manufacturer marks on knives and blades.

🔹 Industrial Fasteners – Mark batch numbers, tolerance markings, and regulatory labels on nuts, bolts, and washers.

🔹 Machine Plates – Permanently mark metal nameplates and safety instructions.

Why it’s perfect for tools? The CCD visual system guarantees that your markings are always in the right place, no matter the complexity.

💡 Why Choose CCD Visual Position Laser Marking Machine?

✅ No need for costly fixtures or manual adjustments—save on labor costs and reduce setup times.

✅ Unmatched precision for ultra-small, irregular, or complex parts, with accuracy as high as 0.01mm.

✅ High-speed, high-volume production—perfect for industries with large quantities of parts.

✅ Versatile—ideal for marking on a wide range of materials like metal, plastics, and coated surfaces.

The CCD Visual Position Laser Marking Machine is the ultimate solution for industries that demand accuracy, efficiency, and automation.

📩 Contact us now for more information on how the CCD Visual Position Laser Marking Machine can transform your marking process and help your business thrive!

Why You Need the CCD Visual Laser Marking Machine – A Game Changer for Your Business!

Are you tired of dealing with production errors? Wasting time on manual adjustments? Or struggling with inconsistent product quality? The CCD Visual Laser Marking Machine is here to change the game. This powerful piece of technology is exactly what your business needs to level up, boost efficiency, and maximize profits.

1. Precision Like You’ve Never Seen Before

Imagine your laser marking system aligning and focusing with absolute precision—every single time. No more wasted time. No more mistakes. The CCD Visual Laser Marking Machine uses cutting-edge vision technology to capture real-time images of your workpieces. This means that whether you’re marking intricate designs, barcodes, or serial numbers, the laser hits exactly where it’s supposed to, every time.

This unmatched accuracy eliminates errors and gives you peace of mind, knowing that your products will always meet the highest standards.

2. Save Time, Save Money: Boost Your Productivity

Time is money, and the CCD Visual Laser Marking Machine is all about saving both. With its automated alignment system, you don’t need to waste hours on manual setup or adjustments. The machine automatically detects the exact position of each item and adjusts the laser for optimal results.

The result? Faster setup, quicker production cycles, and the ability to process more orders in less time. Imagine getting your products out the door faster, increasing your output, and dramatically boosting your revenue.

3. Versatility for Every Job, Every Material

Whether you’re marking metal, plastic, glass, or other materials, this machine handles it all. The CCD vision system automatically adjusts to different shapes, sizes, and surfaces, making it perfect for any project you throw at it. You don’t have to buy multiple machines for different materials or products.

With the CCD Visual Laser Marking Machine, you can seamlessly switch between projects without sacrificing quality. It’s the kind of versatility that saves you time, money, and resources.

4. Eliminate Mistakes – Consistency You Can Count On

The best part? The CCD Visual Laser Marking Machine is designed to virtually eliminate human error. Forget about those frustrating misaligned markings or errors that cost you both time and money. This machine ensures perfect consistency with every single product.

With its real-time feedback system, if something’s wrong, the machine will catch it immediately and make adjustments. That means no more costly rework or returns. You’re delivering high-quality products every time.

5. Increase Your ROI with a Single Machine

This isn’t just an investment in new technology—it’s an investment in your bottom line. With its low maintenance, high speed, and exceptional reliability, the CCD Visual Laser Marking Machine will pay for itself in no time.

Fewer mistakes, faster production, and improved product quality all translate into higher profits. Think about it: fewer resources spent on rework, reduced waste, and more products shipped out the door—all leading to higher customer satisfaction and repeat business.

6. A Tool That Grows with Your Business

Whether you’re a small business just starting out or a large enterprise with high-volume needs, this machine adapts to any scale of operation. It’s built to grow with you, handling everything from low-run custom jobs to high-speed mass production.

It’s the future-proof investment that ensures you stay competitive, efficient, and profitable for years to come.

Why Wait? Elevate Your Business with the CCD Visual Laser Marking Machine Today!

The CCD Visual Laser Marking Machine is not just a tool—it’s the solution to your production headaches. Faster, more accurate, and more efficient than anything else on the market, it will change the way you work.

Take action now! Don’t let your competitors get ahead by staying stuck in the past with outdated equipment. Upgrade today and experience the speed, precision, and versatility that will help your business soar to new heights.

Ready to see the difference? [Order your CCD Visual Laser Marking Machine now!]

Frequently Asked Questions (FAQ) – CCD Visual Position Laser Marking Machine

1️⃣ What is a CCD Visual Position Laser Marking Machine?

A CCD Visual Position Laser Marking Machine uses a CCD camera system for accurate positioning and alignment of the laser on the material’s surface. This machine combines laser marking with visual recognition technology, ensuring high precision when marking complex or irregularly shaped objects. The system automatically adjusts the laser’s position based on the camera’s feedback, making it perfect for high-accuracy tasks such as component marking, serial number engraving, and logo positioning.

2️⃣ How does the CCD camera assist in laser marking?

The CCD camera in the machine provides real-time feedback, allowing the system to accurately detect and align the material and the design to be marked. It enables precise placement of the laser on complex or non-flat surfaces by detecting reference points and contours of the objects. This ensures that each marking is perfectly positioned, even on irregular or hard-to-align parts.

3️⃣ What are the key benefits of using a CCD Visual Position Laser Marking Machine?

- High Precision: The CCD camera ensures accurate laser positioning, even for small or irregularly shaped items.

- Automatic Alignment: The machine automatically adjusts the laser’s position, eliminating manual setup and reducing human error.

- Increased Efficiency: With the visual system, the machine can mark a wide variety of shapes and sizes quickly, improving productivity.

- Versatility: It can mark on a range of materials, including metal, plastic, glass, and ceramics, providing broad application potential.

- Minimized Downtime: Automatic alignment reduces setup time, making it ideal for high-volume production environments.

4️⃣ What materials can the CCD Visual Position Laser Marking Machine handle?

This machine is capable of marking a wide variety of materials, including:

- Metals (steel, aluminum, copper, etc.)

- Plastics (ABS, PVC, etc.)

- Ceramics

- Glass

- Leather

- Wood

- Rubber

It is ideal for industries such as electronics, automotive, medical devices, packaging, and consumer products that require precise marking on a range of materials.

5️⃣ Can the CCD Visual Position Laser Marking Machine handle complex designs?

Yes, the machine is highly effective for complex designs, including detailed logos, serial numbers, barcodes, QR codes, and even 3D patterns. The CCD camera system ensures that even intricate or non-standard designs are aligned perfectly, guaranteeing high-quality results without the need for manual adjustments.

6️⃣ What is the marking area of the CCD Visual Position Laser Marking Machine?

The marking area typically ranges from 50mm x 50mm to 300mm x 300mm, depending on the machine model. Some machines also offer optional larger marking areas for applications requiring more extensive marking on large parts.

7️⃣ How does the system handle different sizes and shapes of materials?

The CCD Visual Position Laser Marking Machine is designed to work seamlessly with irregularly shaped or non-flat materials. Thanks to the camera system, the machine automatically adjusts the laser’s position to ensure accurate marking, regardless of the shape or orientation of the material. This feature is especially useful for marking curved surfaces, small parts, or objects with variable dimensions.

8️⃣ Is the machine easy to operate?

Yes, the CCD Visual Position Laser Marking Machine comes with user-friendly software and an intuitive interface. The system can automatically detect and align the laser for quick setup and operation. The software also allows for easy design uploading, real-time adjustments, and position monitoring, making it suitable for both novice and experienced users.

9️⃣ What industries benefit from using the CCD Visual Position Laser Marking Machine?

- Electronics: Marking of circuit boards, IC chips, and components.

- Automotive: Engraving serial numbers, VINs, and logos on car parts.

- Medical Devices: Marking instruments, implants, and equipment.

- Consumer Products: Personalizing items like gadgets, accessories, and tools.

- Packaging: Engraving barcode or QR codes on plastic or metal packaging.

- Jewelry: Engraving intricate designs on rings, pendants, and other accessories.

🔟 What is the maintenance required for the CCD Visual Position Laser Marking Machine?

Routine maintenance involves:

- Cleaning the lenses and mirrors to ensure optimal laser performance.

- Checking the alignment of the CCD camera and laser to ensure precision.

- Ensuring the cooling system is functioning properly to prevent overheating.

- Inspecting the system for wear on components like belts and motors.

- Periodically updating the software to ensure compatibility with the latest designs and functions.

1️⃣1️⃣ Can the CCD Visual Position Laser Marking Machine be integrated with automated production lines?

Yes, the CCD Visual Position Laser Marking Machine can be integrated with automated systems, such as conveyor belts, robots, or assembly lines. This makes it ideal for high-speed production environments where precise marking needs to be performed on items moving through a production line.

1️⃣2️⃣ What is the price range for the CCD Visual Position Laser Marking Machine?

The price for the CCD Visual Position Laser Marking Machine varies depending on the laser power, marking area, and additional features. Generally, the price range is between $15,000 to $100,000, depending on the customization and specific requirements for your applications. Pricing may also depend on the software and integration features selected.

CCD Visual Position Laser Marking Video

Request a Quote for a CCD Visual Position Laser Marking Machine

SISMAR LASER has CCD visual Position laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- EZCAD common errorMarch 18, 2025 - 2:09 am

- Small Business Guide: Navigating the Evolving 3D Crystal Engraving Market in 2025March 12, 2025 - 5:31 am

- “Continuous vs. Pulsed Laser Cleaning: Single Mode vs. Multi Mode LasersFebruary 21, 2025 - 5:54 am

- “Laser precision, zero damage—cleaning rust and paint without harming your product.”February 21, 2025 - 3:08 am

- Why Choose glass laser drilling machineJanuary 31, 2025 - 4:59 am