Pedestal Jewelry Laser Welding Machine

/0 Comments/in Products /by linda

200W Jewelry Laser Welding Machine

Pedestal Jewelry Laser Welding Machine

200W Jewelry Laser Welding Machine: Precision and Power 💎

The 200W Jewelry Laser Welding Machine offers high precision and powerful performance for gold, platinum, silver, and titanium welding.

🔹 Key Features:

- 200W Laser for deep, fast welds.

- Precision for intricate repairs and stone setting.

- Ideal for jewelry, electronics, and medical devices.

- Ergonomic design for comfortable operation.

- Advanced cooling system for consistent performance.

Perfect for professionals seeking reliable and precise welding results.

Pedetal jewelry Laser Welding Machine Photo

Transform Your Jewelry Repair with the Pedestal Jewelry Laser Welding Machine ✨

Tired of struggling with traditional welding methods that damage your delicate jewelry? The Pedestal Jewelry Laser Welding Machine is here to revolutionize your repair and crafting process. 🔥

💎 Why This Machine is a Game-Changer:

- Precision & Perfection: Get clean, strong, and accurate welds every time, no matter how intricate the design. No more uneven welds or melted edges—just flawless results.

- Effortless Control: Adjustable power settings allow for precise welding on the finest jewelry, giving you full control over the process.

- Pedestal Design for Flexibility: The pedestal design allows for greater flexibility and ease of use, with the jewelry piece positioned at a comfortable height for the operator. Work with ease, no matter the project.

- High-Precision Microscope: A built-in microscope provides a magnified, crystal-clear view of the welding area, ensuring precise control over every detail of your welding process.

- Optional CCD Camera System: For larger parts, the optional CCD camera system gives you a clear view of the entire marking process, ensuring high-quality results every time.

🚀 Key Benefits:

- Speed & Efficiency: Weld quickly and effectively with minimal heat, preserving the integrity of your pieces.

- Durable Welds: Perfect for repairs and attaching small components without sacrificing strength.

- Compact and Professional: A space-saving pedestal design that integrates seamlessly into your workspace.

Ready to take your jewelry craftsmanship to the next level? The Pedestal Jewelry Laser Welding Machine is the tool you need for precision, speed, and flawless results. Get yours today and start creating the masterpieces you’ve always dreamed of! 🌟

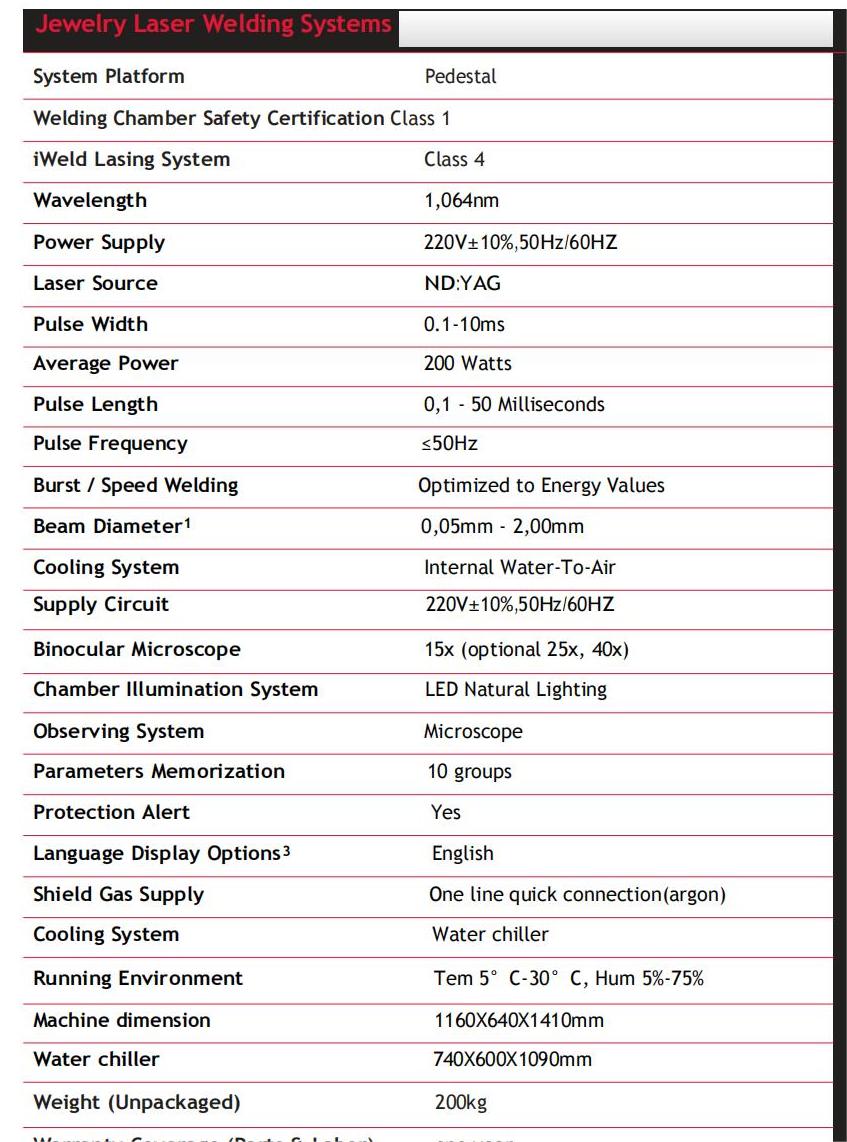

| Category | Details |

|---|---|

| System Platform | Pedestal |

| Welding Chamber Safety Certification Class | Class 1 |

| iWeld Lasing System Class | Class 4 |

| Wavelength | 1,064nm |

| Power Supply | 220V±10%, 50Hz/60HZ |

| Laser Source | ND:YAG |

| Pulse Width | 0.1 – 10ms |

| Average Power | 200 Watts |

| Pulse Length | 0.1 – 50 Milliseconds |

| Pulse Frequency | ≤50Hz |

| Burst / Speed Welding | Optimized to Energy Values |

| Beam Diameter | 0.05mm – 2.00mm |

| Cooling System | Internal Water – To – Air |

| Supply Circuit | 220V±10%, 50Hz/60HZ |

| Binocular Microscope | 15x (optional 25x, 40x) |

| Chamber Illumination System | LED Natural Lighting |

| Observing System | Microscope |

| Parameters Memorization | 10 groups |

| Protection Alert | Yes |

| Language Display Options | English |

| Shield Gas Supply | One line quick connection (argon) |

| Cooling System | Water chiller |

| Running Environment | Temp 5°C – 30°C, Hum 5% – 75% |

| Machine Dimension | 1160X640X1410mm |

| Water Chiller Dimension | 740X600X1090mm |

| Weight (Unpackaged) | 200kg |

Pedestal Jewelry Laser Welding Machine: Precision Meets Performance ✨

Designed with the jewelry professional in mind, the Pedestal Jewelry Laser Welding Machine combines ergonomic design, advanced features, and unmatched precision to deliver flawless results every time.

💎 Key Features of the Pedestal Jewelry Laser Welding Machine:

Ergonomic Design for Comfort: The entire machine is ergonomically designed to meet the jewelry industry’s needs for precision, aesthetic appeal, stable performance, and the ability to handle long-duration and constant processing.

Spacious Interior for Tools & Fixtures: With ample inner space, you can easily store all your tools and fixtures, providing a clutter-free, organized workspace that enhances your productivity.

Smooth & Precise Operation: The machine is equipped with an electric focusing mechanism, digital scale reading display, and a regulating switch for laser parameters, ensuring smoother operation and consistent performance every time.

Easy Maintenance: The replaceable dust screen allows for easy cleaning of the work area, while the recycling system keeps your workspace clean by efficiently handling welding slag.

Clear Visibility for Precision Welding: Featuring an LED ring-shaped astral lamp for bright illumination and a high-quality German-imported microscope, the welding position is crystal-clear, enabling you to see even the finest details.

Precise Light Spot for Perfect Welds: The precise light spot ensures that the machine meets the highest standards of precision welding, making it perfect for delicate jewelry work.

🚀 Why Choose This Machine?

- Effortless Comfort with ergonomic design.

- Crystal-clear Observation for perfect results.

- Advanced Features for flawless, reliable welds.

Step up your jewelry game with the Pedestal Jewelry Laser Welding Machine—your ultimate tool for precision, efficiency, and long-lasting performance. 🌟

Applications of the Pedestal Jewelry Laser Welding Machine ✨

The Pedestal Jewelry Laser Welding Machine is an essential tool for a variety of industries, offering precision welding for a wide range of materials. Its versatility makes it a go-to solution in the following sectors:

💎 Key Applications:

- Aviation & Aerospace: Perfect for welding delicate components in high-precision industries.

- Jewelry: Ideal for silver, platinum, titanium, and stainless steel jewelry, including point welds, fill hole repairs, and setting precious stones and claw feet.

- Sports Equipment: Precision welding for golf club heads and other sporting goods.

- Medical Equipment: Used for welding medical devices and aluminum dentures, ensuring durability and accuracy.

- Electronics & Instruments: Essential for welding electronic parts and precision instruments.

- Automotive: A valuable tool in the automotive industry for welding various parts with precision.

With its advanced features, this machine can tackle even the most demanding welding tasks, making it indispensable across these industries. 🌟

FAQ – Pedestal Jewelry Laser Welding Machine

1️⃣ What is a Pedestal Jewelry Laser Welding Machine?

A Pedestal Jewelry Laser Welding Machine is a specialized device used for precision welding of metal parts, primarily for jewelry manufacturing and repair. It utilizes focused laser beams to melt and fuse metals without damaging the surrounding material, offering clean, precise, and efficient welding.

2️⃣ How does a Pedestal Jewelry Laser Welding Machine work?

The machine emits a highly focused laser beam that targets the joint area of the metals to be welded. The heat generated by the laser beam causes the metals to melt and bond together. It is commonly used for delicate tasks, such as repairing jewelry, resizing rings, or welding small components without disturbing the surrounding material.

3️⃣ What materials can be welded with this machine?

It is primarily used for welding precious metals such as gold, silver, platinum, and palladium, as well as other alloys and materials commonly found in jewelry making. It can also handle some base metals like copper and stainless steel, depending on the machine specifications.

4️⃣ What are the key advantages of using a Pedestal Jewelry Laser Welding Machine?

- Precision: The laser offers highly focused energy, making it ideal for small, delicate welds on intricate jewelry designs.

- Minimal Heat Affected Zone (HAZ): The laser’s precise control ensures minimal distortion and heat damage to the surrounding material.

- No Need for Filler Material: In many cases, the welding can be done without the need for additional filler material, preserving the appearance of the piece.

- Increased Efficiency: Fast welding times and reduced labor costs, leading to improved productivity.

- Clean Finish: The laser beam produces a clean, smooth weld without the need for post-processing.

5️⃣ Is the Pedestal Jewelry Laser Welding Machine easy to use?

Yes, the machine is designed to be user-friendly, with an intuitive control system. Many models come with touchscreens, adjustable settings for different materials, and fine-tuning capabilities for weld depth and power. Training is typically minimal, but learning the best settings for different types of jewelry may take a little practice.

6️⃣ What safety precautions should be taken when using the machine?

- Eye Protection: Always wear specialized laser safety glasses to protect your eyes from the intense light produced by the machine.

- Ventilation: Ensure proper ventilation to avoid inhaling fumes produced during the welding process, especially when working with alloys that may release hazardous fumes.

- Protective Gear: Wear appropriate clothing and gloves to avoid burns or injuries from the laser or hot metal.

7️⃣ Can I repair my jewelry with this machine?

Yes, Pedestal Jewelry Laser Welding Machines are commonly used for jewelry repair, including fixing broken clasps, resizing rings, reattaching stones, and more. Their precision allows for effective repairs without the need for extensive reworking of the piece.

8️⃣ What is the difference between a Pedestal Jewelry Laser Welding Machine and a standard laser welding machine?

The main difference lies in the design and function. A pedestal model is typically more compact and has a more ergonomic design, making it suitable for smaller, delicate pieces like jewelry. Standard laser welders may be larger and intended for more general applications, such as industrial or automotive welding.

9️⃣ How much does a Pedestal Jewelry Laser Welding Machine cost?

The cost varies depending on the brand, features, and specifications of the machine. Prices typically range from $5,000 to $20,000 USD. While the initial investment can be significant, the machine’s efficiency and the quality of the welds it produces can result in long-term savings and a return on investment.

🔟 What maintenance is required for the Pedestal Jewelry Laser Welding Machine?

Regular maintenance is necessary to keep the machine running smoothly:

- Clean the laser lens and mirrors regularly to ensure optimal performance.

- Check the cooling system to prevent overheating.

- Calibrate the machine periodically for accuracy.

- Replace any worn-out parts, such as laser tubes or fuses, as required.

Jewelry Laser Welding video

Request a Quote for a Jewelry Laser Welding Machine

SISMAR LASER has laser welding machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser welding system or an excellent choice for your first laser machine.

Request a quote for a high-quality jewelry laser welding machine that exceeds your expectations. You can also schedule a demo to see how jewelry laser welding machine works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.